Printed board switching test method

A test method and technology for printed boards, applied in the field of testing, can solve problems such as poor practicability, and achieve the effects of good practicability, improved work efficiency, and rapid and accurate judgment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

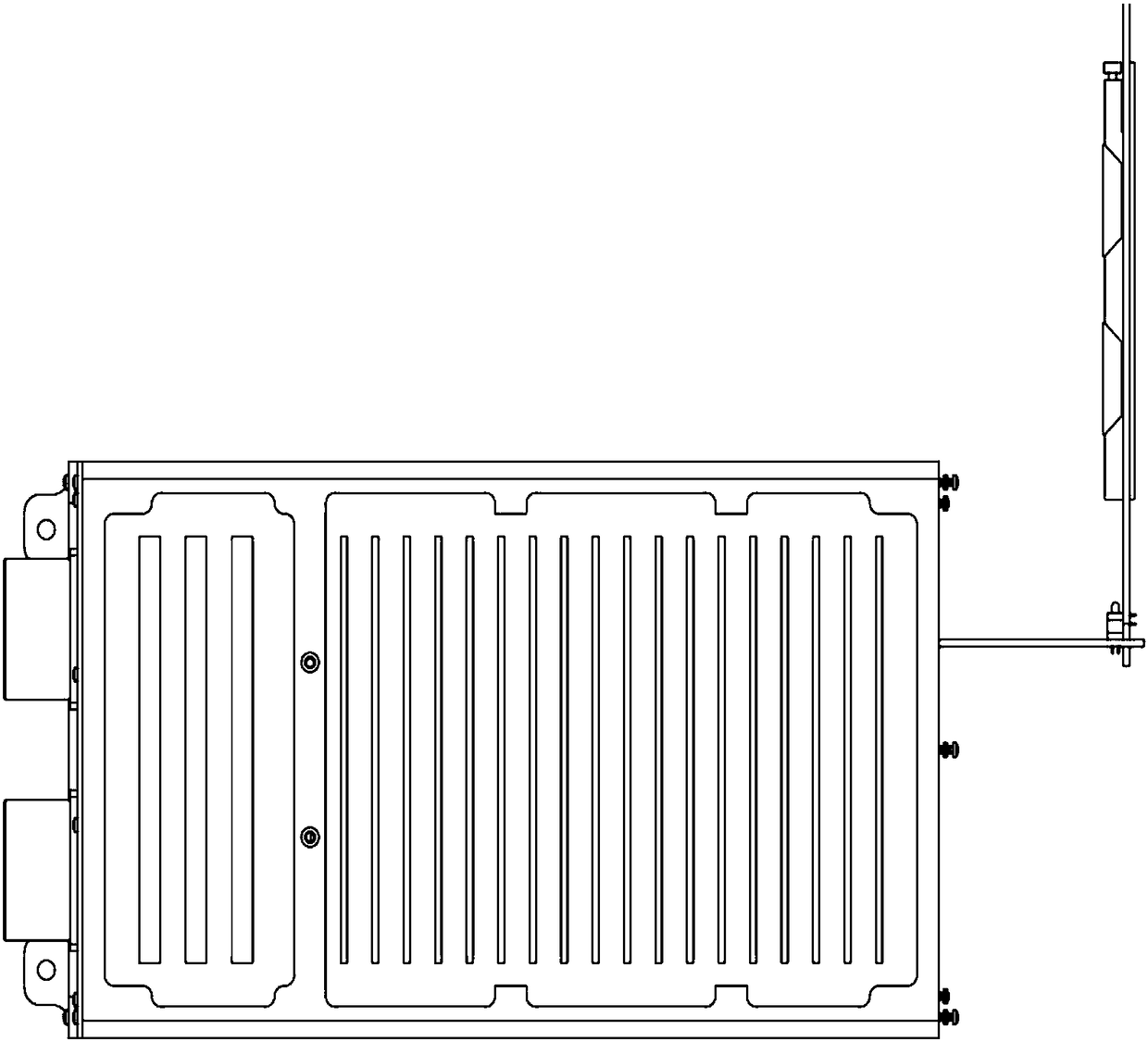

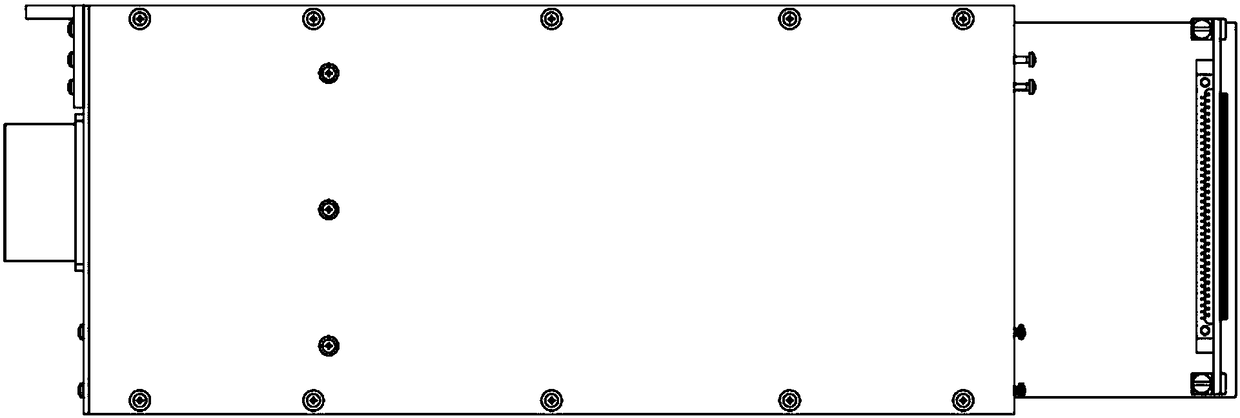

[0016] refer to Figure 1-3 . The specific steps of the printed board transfer test method of the present invention are as follows:

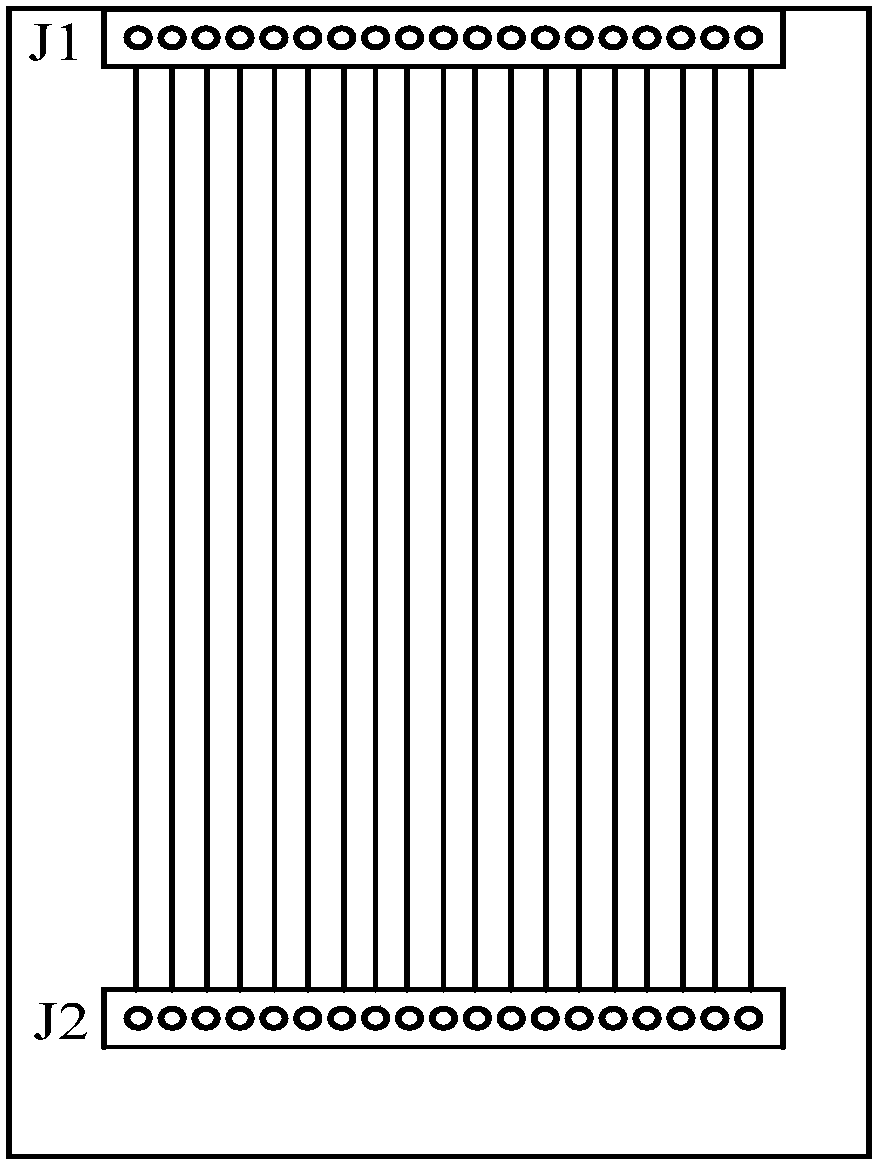

[0017] Design the circuit adapter board, the circuit adapter board extends out of the control box, the two ends of the circuit adapter board are installed with the same type of plug J1 as the printed board to be tested, and the socket J2 that matches the type of the plug J1, and the edge of the plug J1 is in line with the The edges of the adapter board are overlapped, and each core of the plug J1 and the socket J2 of the circuit adapter board is connected by wiring on the component surface or the welding surface of the printed board.

[0018] Use the following steps when using the printed board transfer debugging method:

[0019] Step 1. Ensure that the control box is in the power-off state, and take out the printed board to be tested from the control box;

[0020] Step 2. Refer to figure 2 Insert the plug J1 end of the circuit adapter boar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com