Cable bending radius measurer and detection method

A technology of bending radius and detection method, which is applied in the direction of measuring devices, mechanical measuring devices, instruments, etc., can solve the problems of low measurement accuracy of cable bending radius, achieve wide application and popularization, improve accuracy, and work is simple and easy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The embodiments will be described in detail below in conjunction with the accompanying drawings.

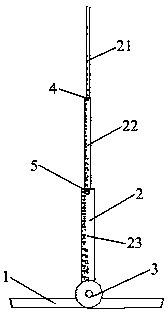

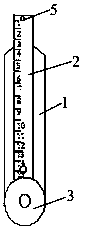

[0017] See attached figure 1 And attached figure 2 , a cable bending radius measuring device, comprising a fixed bracket 1, a retractable scale 2 and a rotating shaft 3, the rotating shaft 3 fixes the fixed bracket 1 and the retractable scale 2 together, and the fixed bracket 1 and the retractable scale Ruler 2 rotates around described rotating shaft 4; Described telescopic scale 2 is to comprise three hollow square cubes, is respectively upper scale 21, middle scale 22 and lower scale 23, and described upper scale 21, middle scale Ruler 22 and lower scale 23 external diameters increase progressively; Described upper scale 21 can be received in the middle scale 22, and described middle scale 22 can be received in the lower scale 23, and described upper scale 21, middle scale All mark scale marks on chi 22 and lower scale 23; Described middle scale 22 tops are provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com