Device for regulating and controlling thin film material growth through substrate electrification

A thin-film material and substrate technology, which is applied in the field of devices for regulating the growth of thin-film materials, can solve the problems of limited ability to control the structure of two-dimensional materials, incapable of substrate adsorption performance, electronic energy state and catalytic activity regulation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Embodiment 1, the process of power-on device and preparation thin film material on metal substrate

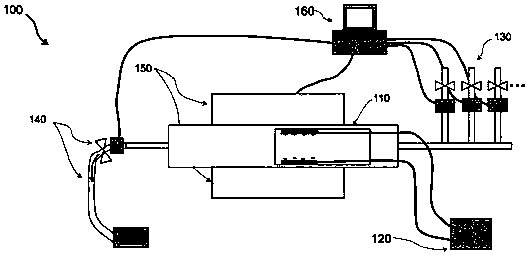

[0058] In this example, the controllable preparation device of two-dimensional thin film materials such as figure 1 As shown, the apparatus 100 includes a CVD reaction chamber 110 , a substrate power supply system 120 , a reaction gas management system 130 , an exhaust management system 140 , a heating system 150 and a central control system 160 .

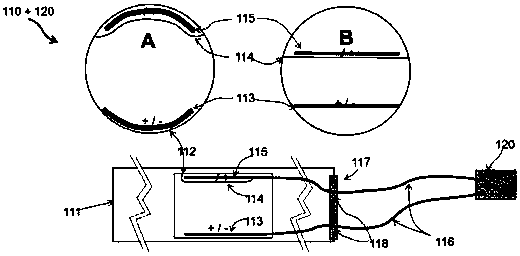

[0059] In order to facilitate placing the substrate, connecting the circuit, and quickly pulling the temperature up and down, a CVD reaction chamber 110 with an inner and outer sleeve structure is used in this embodiment. Such as figure 2 As shown, 111 and 112 are respectively a large quartz tube and a quartz casing, both of which are made of quartz. The large quartz tube 111 has an outer diameter of 50 mm, an inner diameter of 44 mm, and a length of 1800 mm; the outer diameter of the quartz sleeve 112 is 42 mm, an inner di...

Embodiment 2

[0063] Embodiment 2, the process of applying power to the insulating substrate and preparing the thin film material

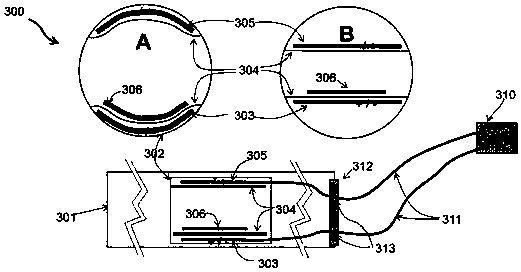

[0064] In this embodiment, the reaction chamber and substrate power supply system in the controllable preparation device of two-dimensional thin film materials are as follows: image 3 shown. Other parts of the device such as CVD reaction chamber, reaction substrate power supply system, reaction gas management system, exhaust management system, heating system and central control system, etc. figure 1 shown.

[0065] In order to facilitate the placement of the substrate, connection of the circuit, and rapid heating and cooling, the CVD reaction chamber 300 with an inner and outer sleeve structure is used in this embodiment. Such as image 3 As shown, 301 and 302 are respectively a large quartz tube and a quartz casing, both of which are made of quartz. The large quartz tube 301 has an outer diameter of 50 mm, an inner diameter of 44 mm, and a length of 1800 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com