Universal compression moulding mould for forming flat plate type composite material components with large sizes and different thicknesses

A technology of composite material components and compression molding, which can be applied to household appliances, other household appliances, applications, etc., and can solve problems such as low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

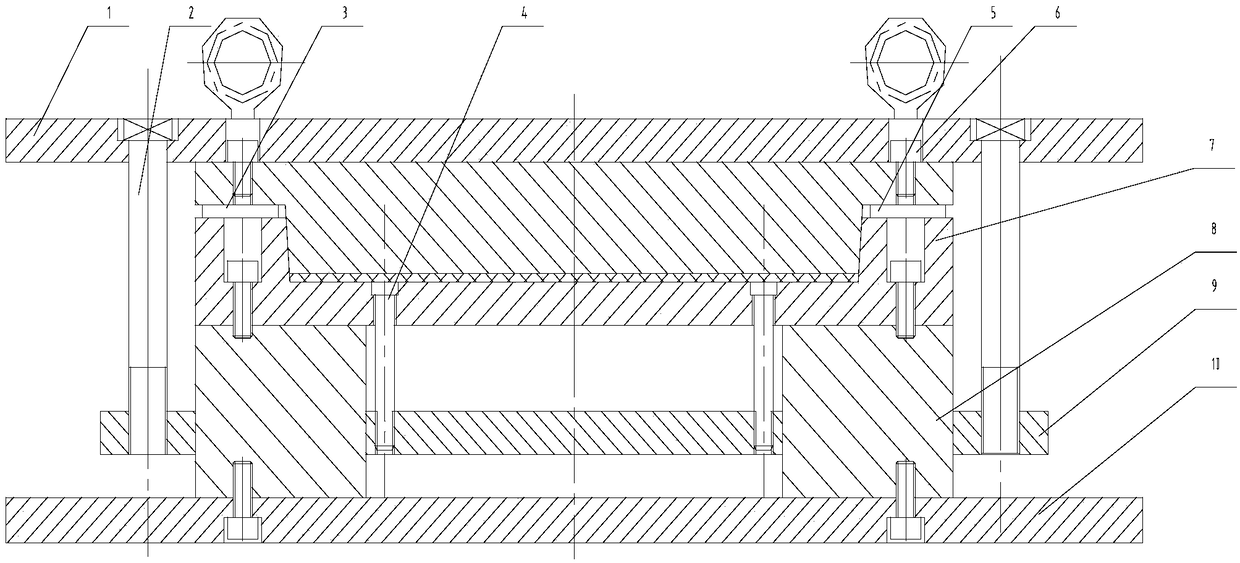

[0041] The invention provides a molding die for forming composite material components with different thicknesses, which includes a top plate 1, a demoulding screw 2, a punch 3, an ejector rod 4, a pressing block 5, an inner hexagonal screw 6, a die 7, and a support column 8. Support plate 9, base plate 10, hoisting ring 14.

[0042] Among them, the mold adopts the upper and lower half structure.

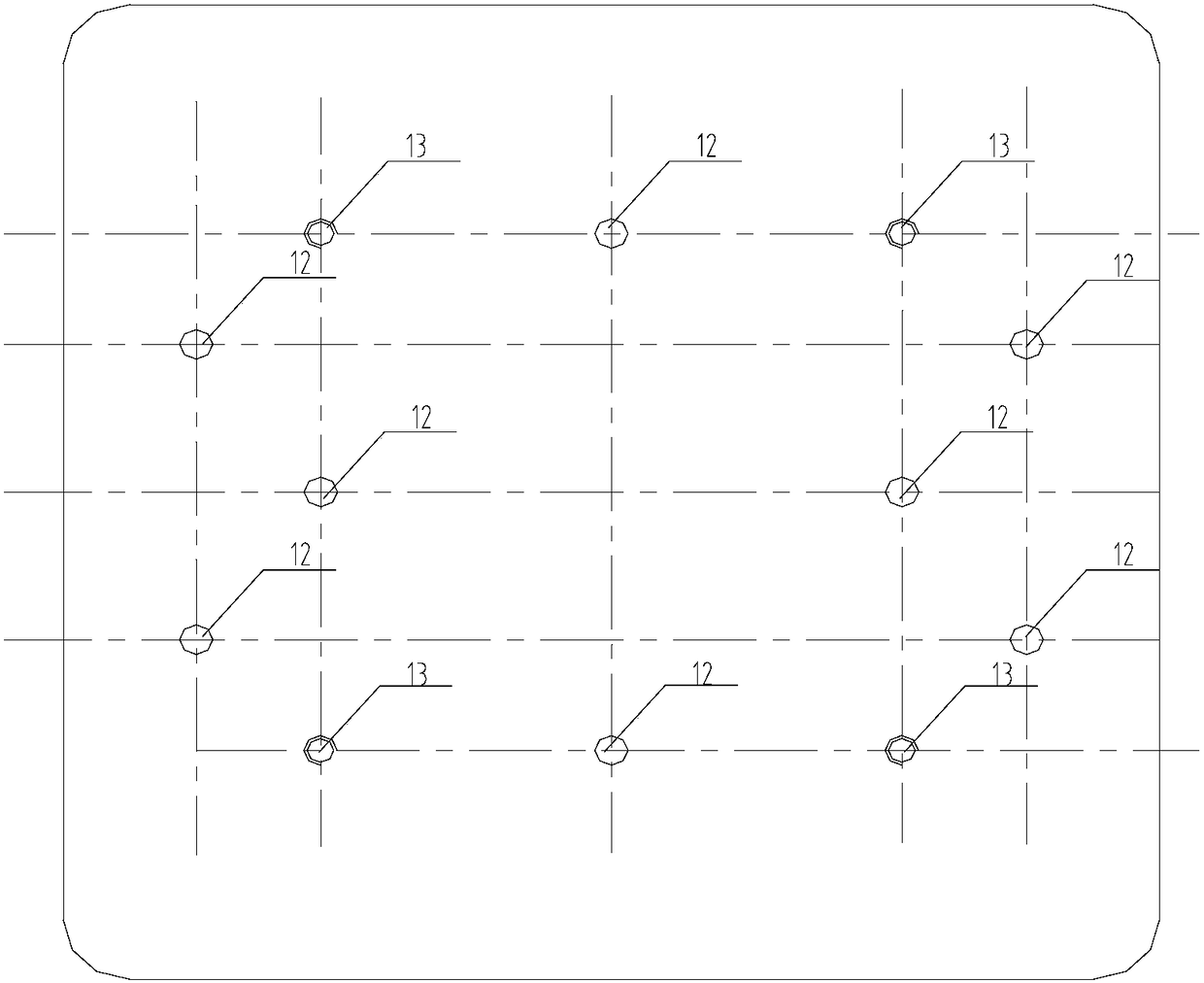

[0043] The top plate 1 is a flat plate structure, on which there are 4 hoisting threaded holes 13 for installing hoisting rings 14; 4 connection positioning holes 12 for installing demoulding screws 2; 11.

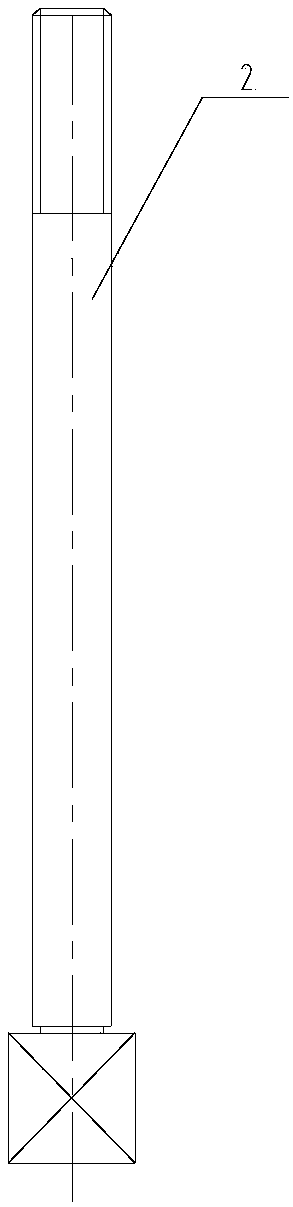

[0044] The demoulding screw 2 is a slender cylindrical structure with a screw thread at one end and is connected with the base plate 9; the other end is a rectangular block structure and is provided with an undercut for convenient installation.

[0045] The punch cavity structure of the punch 3 has a taper, and is provided with a threaded connection hole 11 for connecting with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com