A kind of pliers for bar upsetting

A bar material and upsetting technology, applied in forging/pressing/hammer devices, forging/pressing/hammering machinery, manufacturing tools, etc., can solve problems such as easy bending of bars, affecting production efficiency, and becoming S-shaped, etc. Achieve the effect of avoiding bending and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

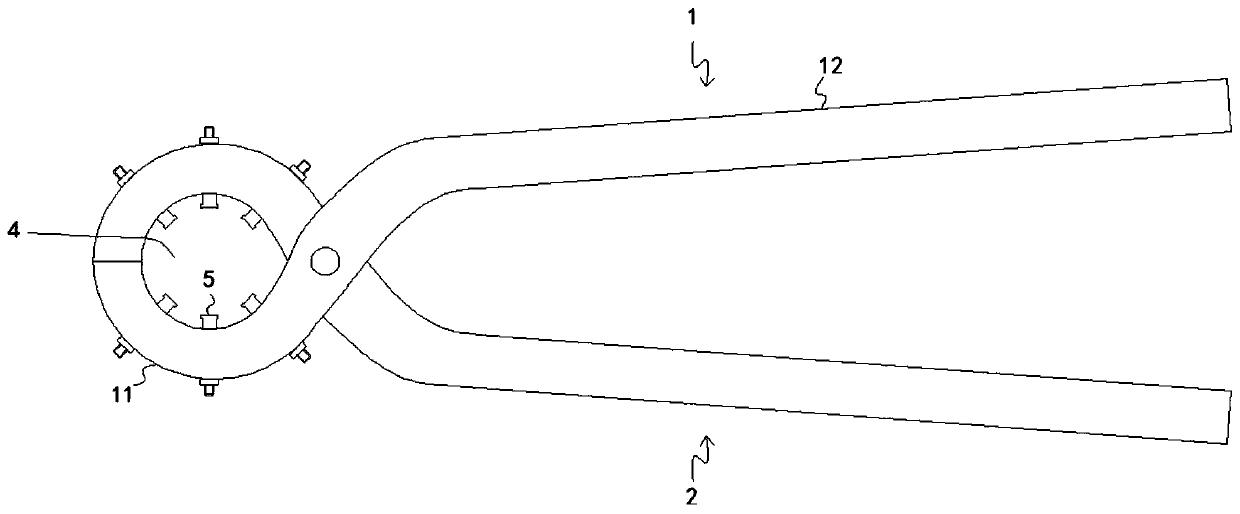

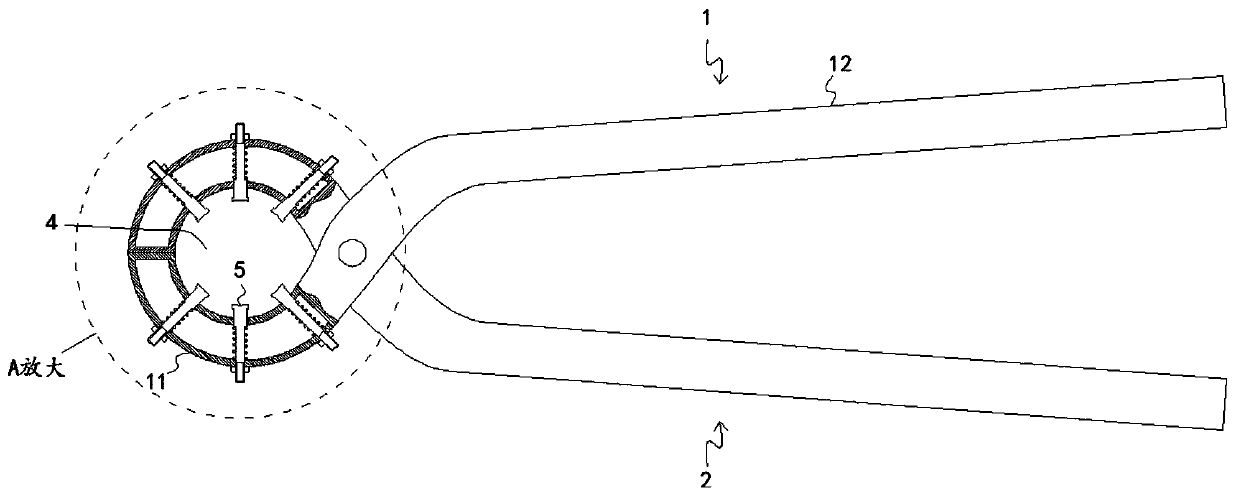

[0021] Such as Figure 1 to Figure 5 As shown, the pliers for upsetting bar 3 in this embodiment includes a first tong bar 1 and a second tong bar 2;

[0022] The first pliers bar 1 comprises an end 11 and a handle part 12, and the end 11 is in the shape of a semicircle; the second pliers bar 2 has the same structure as the first pliers bar 1; The junction of the handle portion 11 and the handle portion 12 forms a hinge. When the first pliers bar 1 and the second pliers bar 2 are merged, the end 11 of the first pliers bar 1 and the end 11 of the second pliers bar 2 are enclosed to form a Cavity 4 for accommodating bar stock 3;

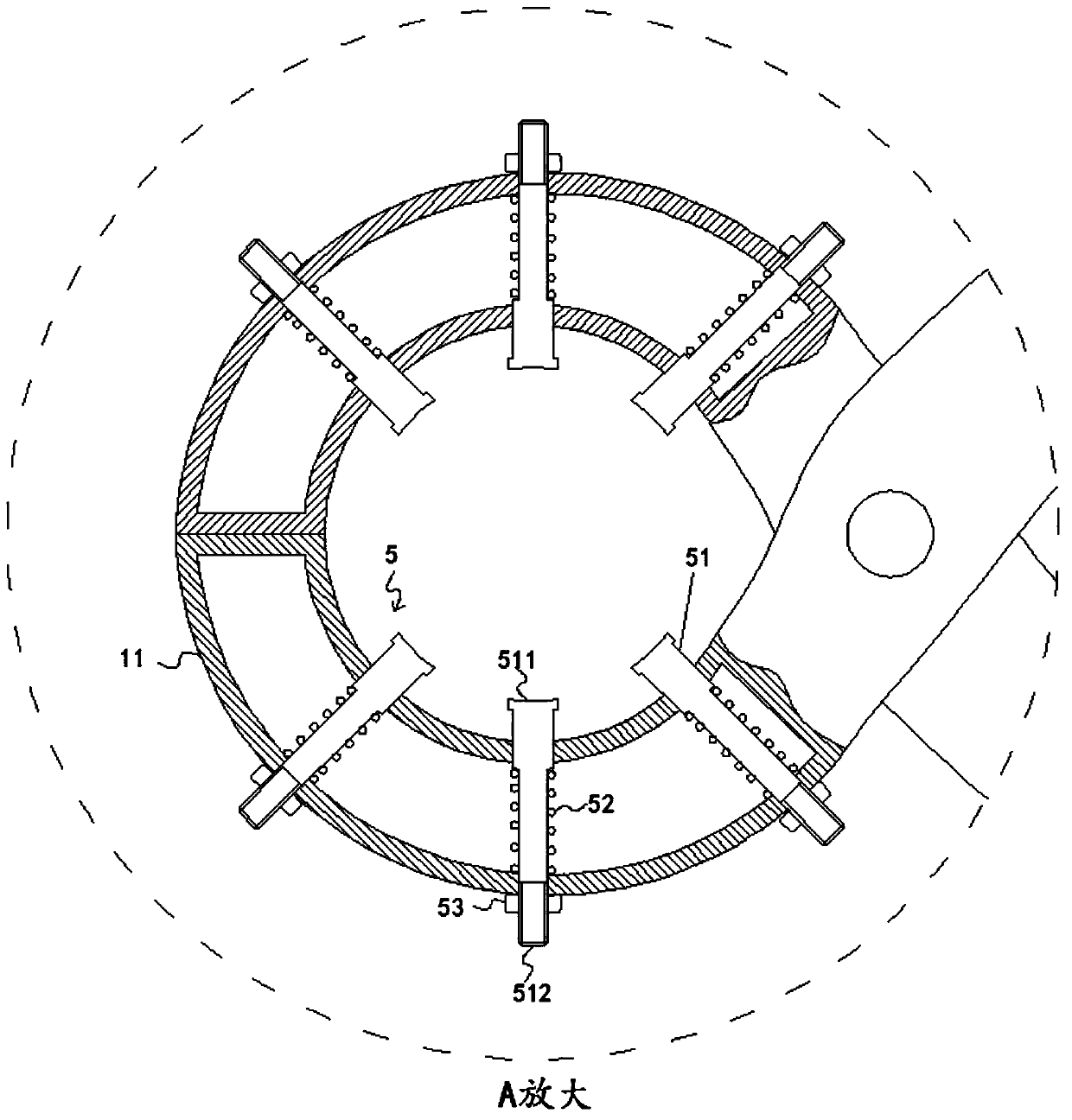

[0023] Such as figure 2 and image 3 As shown, the end 11 of the first pliers bar 1 is hollow, and the inner and outer sides of the end 11 are respectively provided with concentric first round holes and second round holes, and the end 11 of the first pliers bar 1 has three sets of first round holes. circular hole and the second circular hole; corr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com