Platinum based catalyst highly dispersed in carrier aluminum oxide as well as preparation method and application thereof

A catalyst and highly dispersed technology, applied in the direction of catalyst activation/preparation, carbon compound catalyst, metal/metal oxide/metal hydroxide catalyst, etc., can solve the problems of activity decline, easy sintering, easy aggregation and growth, etc., to achieve Effect of improving easy sintering and good propane dehydrogenation activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Take Al 2 o 3 The white powder was placed in a 200mL crucible and placed in a muffle furnace. Roast at 600°C for 5h at a heating rate of 5°C / min. Take 1.6g SiO 2 In a 25mL small beaker.

[0029] (2) Take 0.569g of lanthanum nitrate hexahydrate, 0.403g of indium nitrate hexahydrate, and 0.01g of platinum in a 25mL small beaker, add 0.6mL of deionized water to dissolve.

[0030](3) Add 0.646g of citric acid monohydrate and 0.039mL of ethylene glycol into the above solution, stir to dissolve and mix well.

[0031] (4) Add the solution obtained in (3) dropwise to the Al in (1) 2 o 3 On the carrier, let it stand at room temperature to make it fully impregnated for 24 hours to obtain a gel-like solid.

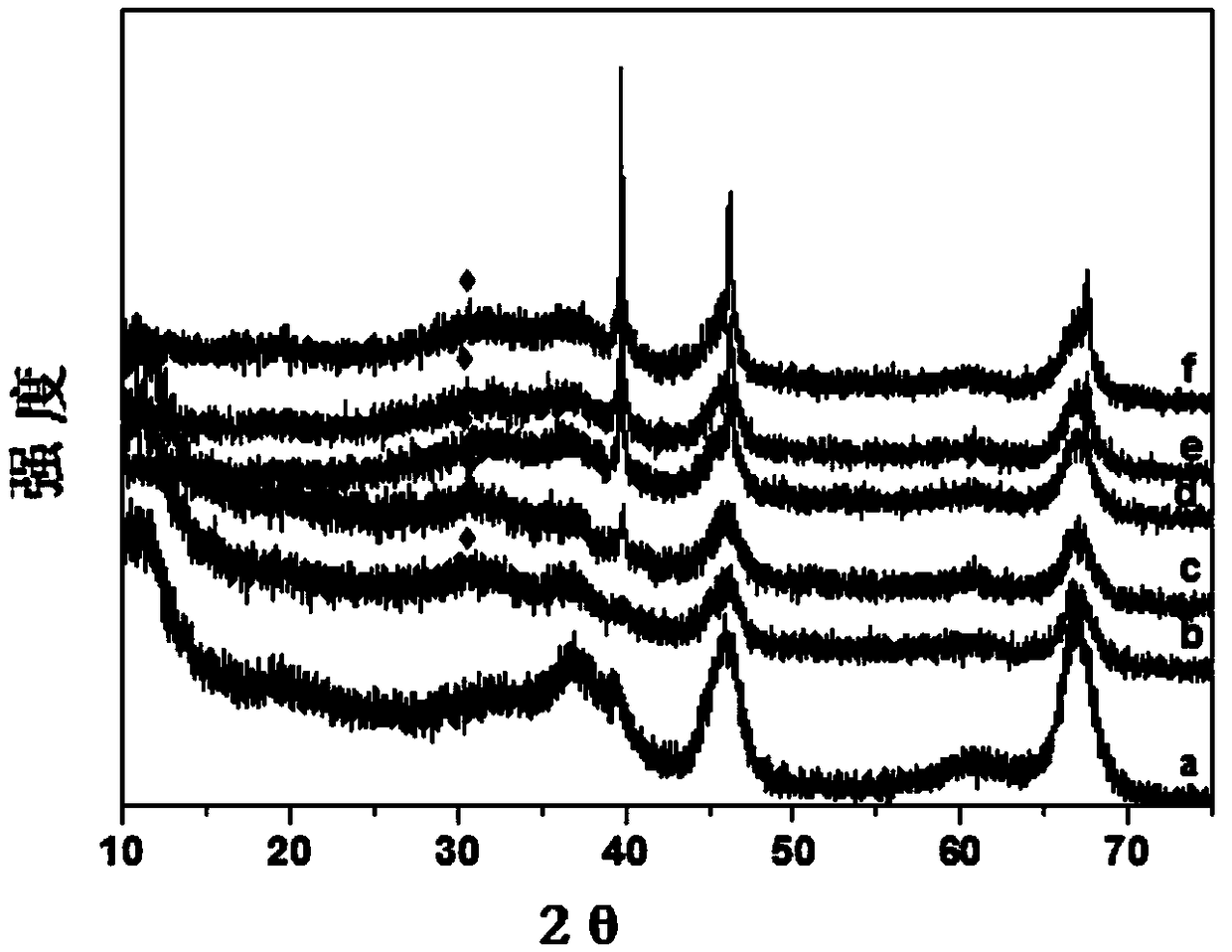

[0032] (5) Dry the above-mentioned gelatinous solid at 80°C for 6h and at 120°C for 12h, and then bake the dried product in a muffle furnace at 350°C for 2h and at 700°C for 5h to obtain LaIn 1-y Pt y o 3 / Al 2 o 3 catalyst precursor.

[0033] (6) LaIn with 0....

Embodiment 2

[0044] The method of Example 1 was used for the reaction, the only difference being that the mass percentage of Pt in the total mass of the catalyst was 0.2%.

Embodiment 3

[0046] The method of Example 1 was used for the reaction, the only difference being that the mass percentage of Pt in the total mass of the catalyst was 1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com