Polyhedral prefabricated combined reinforced concrete toilet and mounting technology thereof

A reinforced concrete and bathroom technology, applied in special buildings, small buildings, building types, etc., can solve the problems of overweight on the construction site, storage of polyhedral prefabricated composite reinforced concrete toilets, inconvenient hoisting on the transportation site, and overweight of non-structural components, etc. , to achieve the effect of ensuring the installation connection strength, avoiding overweight on the construction site, and avoiding overweight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] It will be apparent to those skilled in the art that the invention is not limited to the details of the above-described exemplary embodiments, but that the invention can be embodied in other specific forms without departing from the spirit or essential characteristics of the invention.

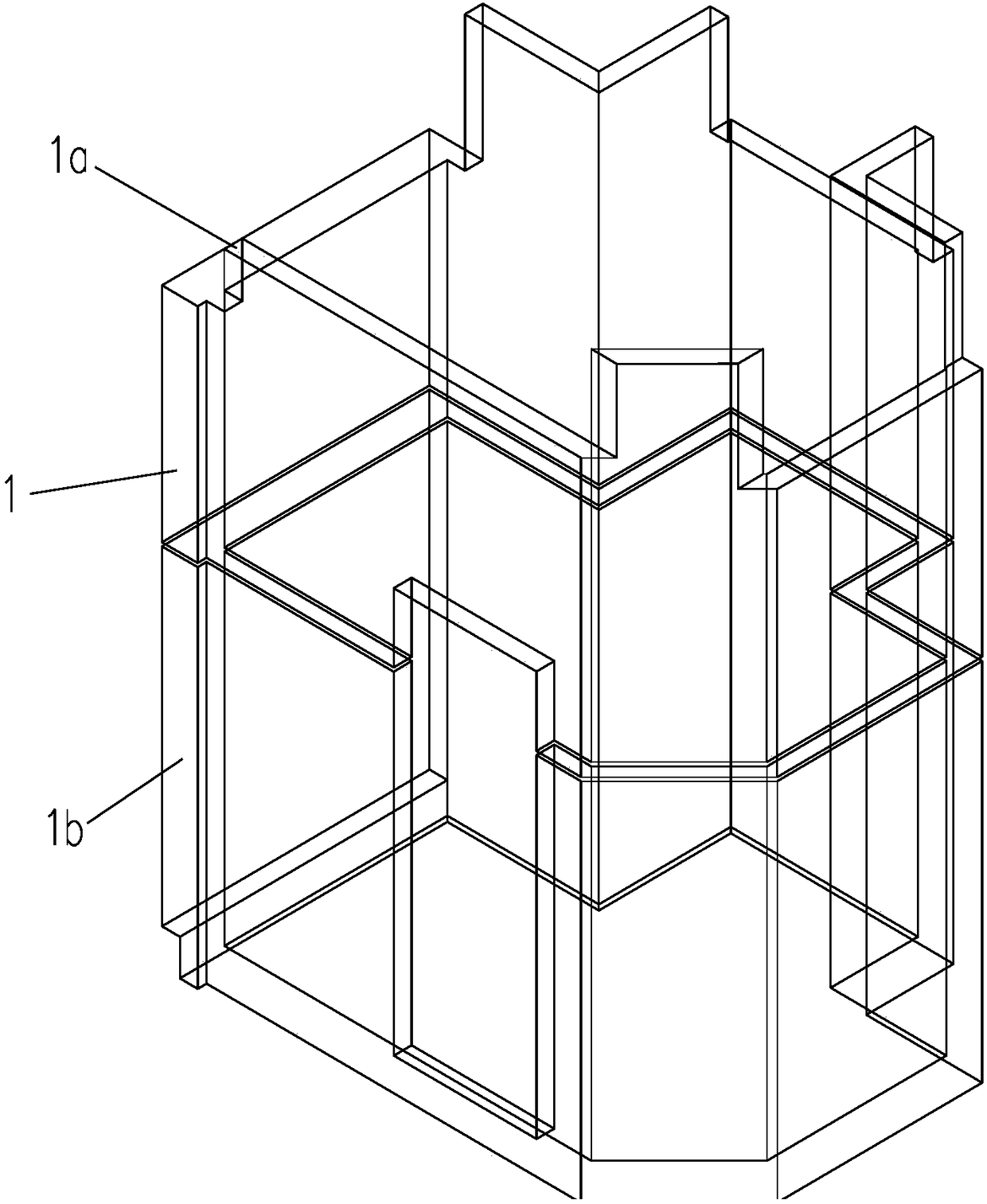

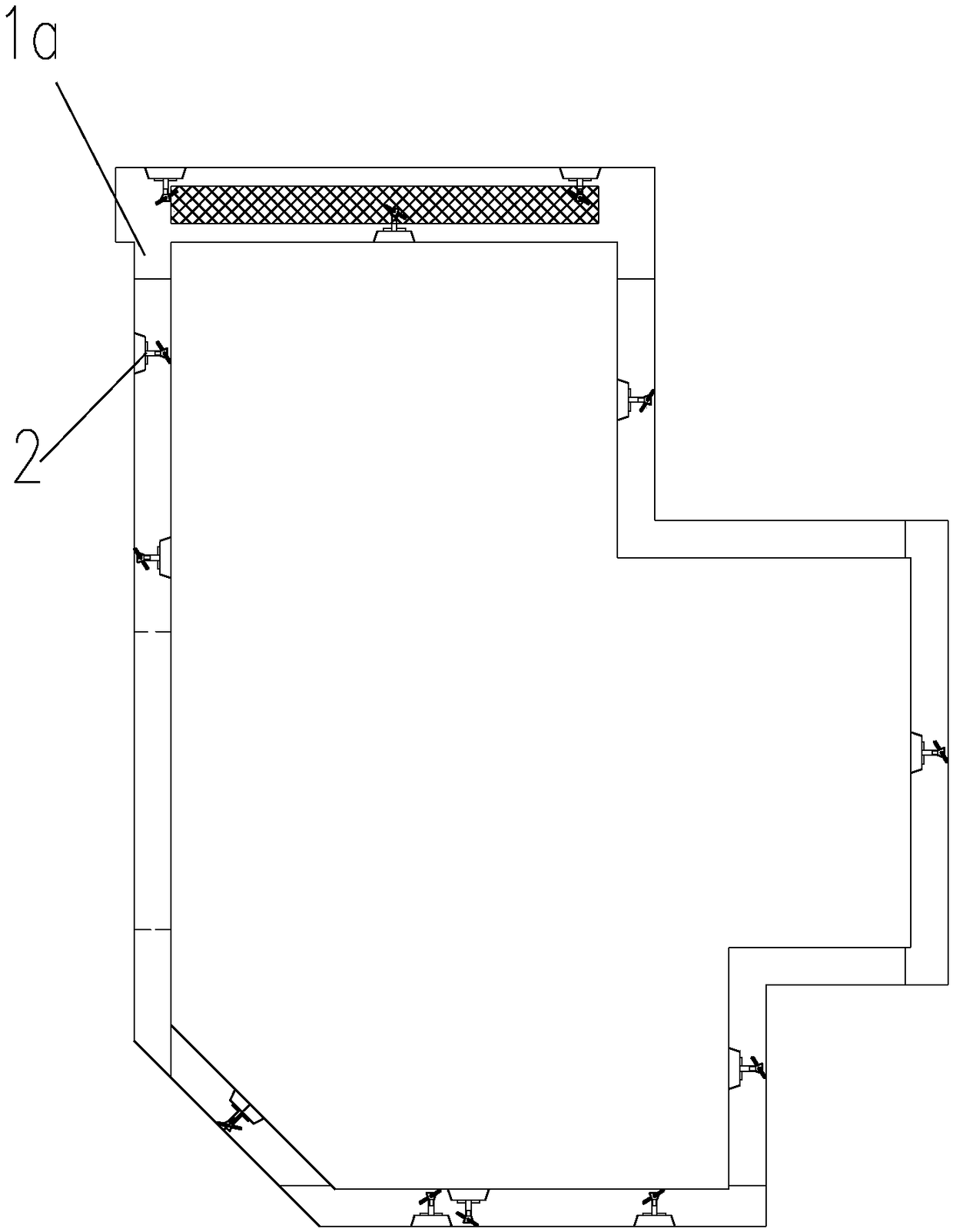

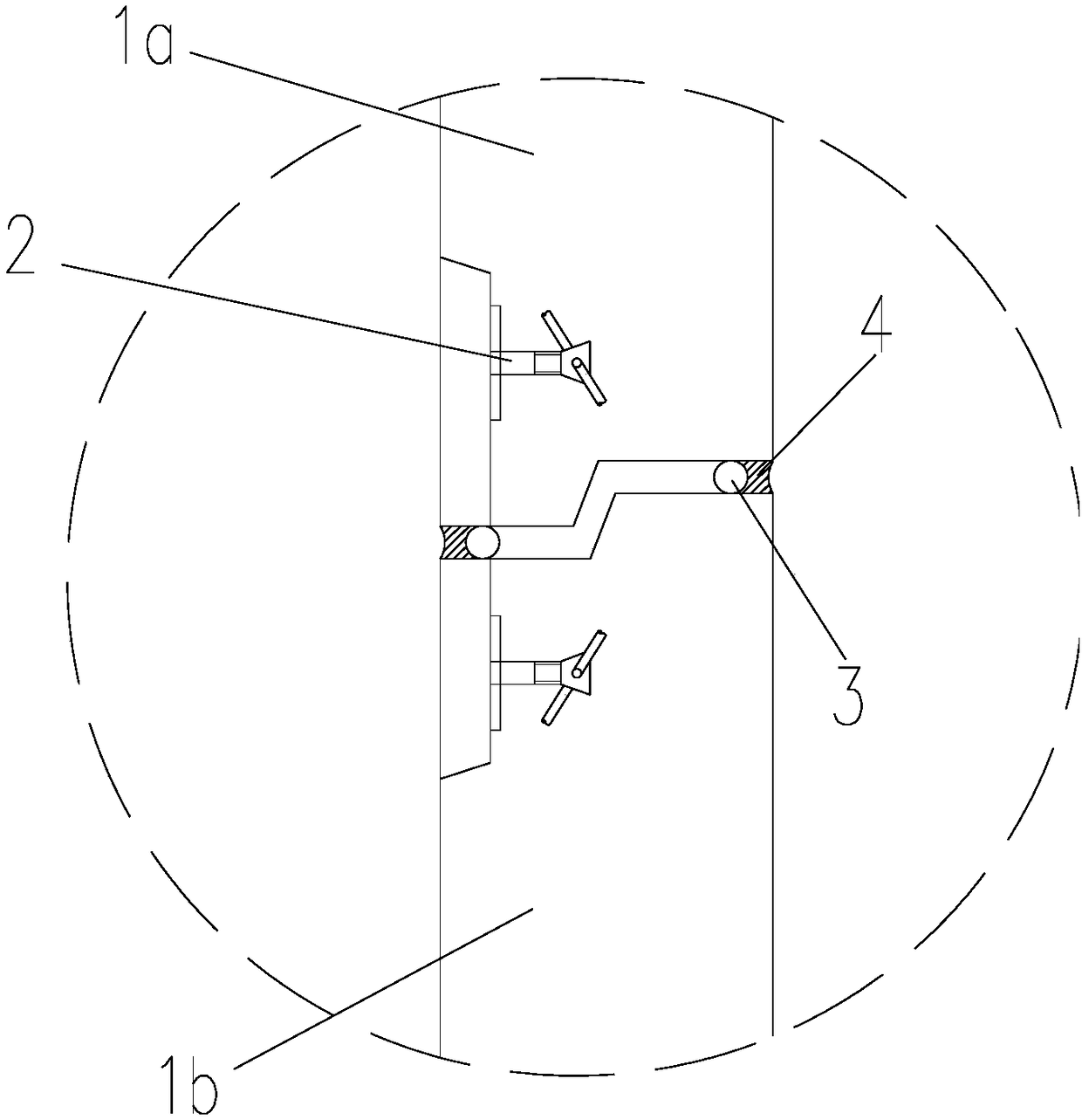

[0033] Referring to the accompanying drawings, a polyhedral prefabricated combined reinforced concrete toilet includes a multifaceted reinforced concrete member 1, and the multifaceted reinforced concrete member 1 includes an upper hanging part 1a and a lower bottom part 1b, both of which are pre-embedded in the upper hanging part 1a and the lower bottom part 1b There are lamp wire tubes, lamp wire boxes and connecting screw parts 2. The lower end surface of the upper hanging part 1a and the upper end surface of the lower bottom part 1b are step-shaped interlocking, and the lower end surface of the upper hanging part 1a and the upper end surface of the lower bottom part 1b A foamed polye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com