Element recycling increasing method in molten iron off-line mixing process

A waterline and blending technology, applied in the field of improving element recycling, can solve the problems of complicated process operation and high production cost, and achieve the effect of reducing alloy consumption, reducing energy consumption and improving environmental protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Improve element recovery and utilization methods in the mixing process outside the molten iron line. The molten iron is mixed into the ladle before tapping the converter. When tapping, the potential energy of the molten steel is used to stir the molten iron directly into molten steel, reducing the addition of carburizers and alloys.

[0037] Specifically include the following steps:

[0038] (1) Control of the loading amount of the converter: according to the normal loading amount, reduce the control by 1.5~2t; the allowable deviation of the total loading amount is ±1t / furnace;

[0039] (2) End-point tapping control: element mass percentage content P≤0.040%, S≤0.040%, 0.06%≤C≤0.09%; temperature 1630℃~1680℃; according to the tapping hole, ladle, alloy addition, etc. The actual production situation adjusts the tapping temperature;

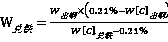

[0040] (3) Hot metal preparation: the chemical composition C, Si, Mn, P, S of the molten iron in the laboratory, the element mass percentage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com