Hydrogen peroxide producing equipment

A production equipment, hydrogen peroxide technology, applied in the direction of peroxide/peroxy hydrate/peroxy acid/superoxide/ozonide, inorganic chemistry, non-metallic elements, etc., can solve the wear and tear of the feeding nozzle and sales volume Limited, high production costs, etc., to achieve the effect of convenient maintenance, lower production costs, and simple assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

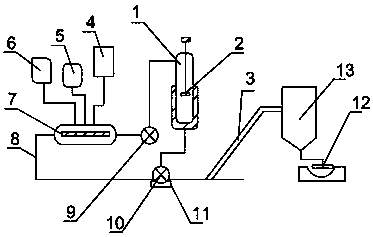

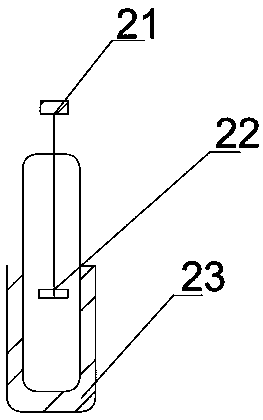

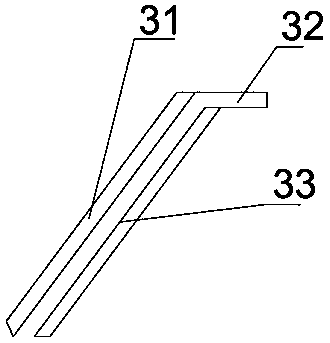

[0023] as attached figure 1 to attach image 3 shown

[0024] The invention provides a hydrogen peroxide production equipment, which is characterized in that the hydrogen peroxide production equipment comprises a stirrer reactor 1, a stirrer 2, a feeding pipe 3, a raw salt tank 4, a Glauber's salt tank 5, a hydrogen peroxide raw material tank 6, and a preparation tank 7 , pipeline 8, first mixed material delivery pump 9, second mixed material delivery pump 10, centrifuge 11, finished product tank 12 and cyclone heat dryer 13, the side of the center of the lower part of the agitator reactor 1 is fixedly equipped with an agitator 2. The right end of the agitator 2 is fixedly provided with a feeding pipe 3, and the right end of the feeding pipe 3 is fixedly provided with a cyclone heat dryer 13, and the right end of the lower part of the cyclone heat dryer 13 is fixedly installed There is a finished product tank 12, a centrifuge 11 is fixedly arranged on the left side of the ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com