Plate cabinet mounting lifting frame of urban rail transit power supply system

A technology of urban rail transit and power supply system, which is applied in the field of panel installation and lifting frame of urban rail transit power supply system. The effect of convenient transportation and low overall weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

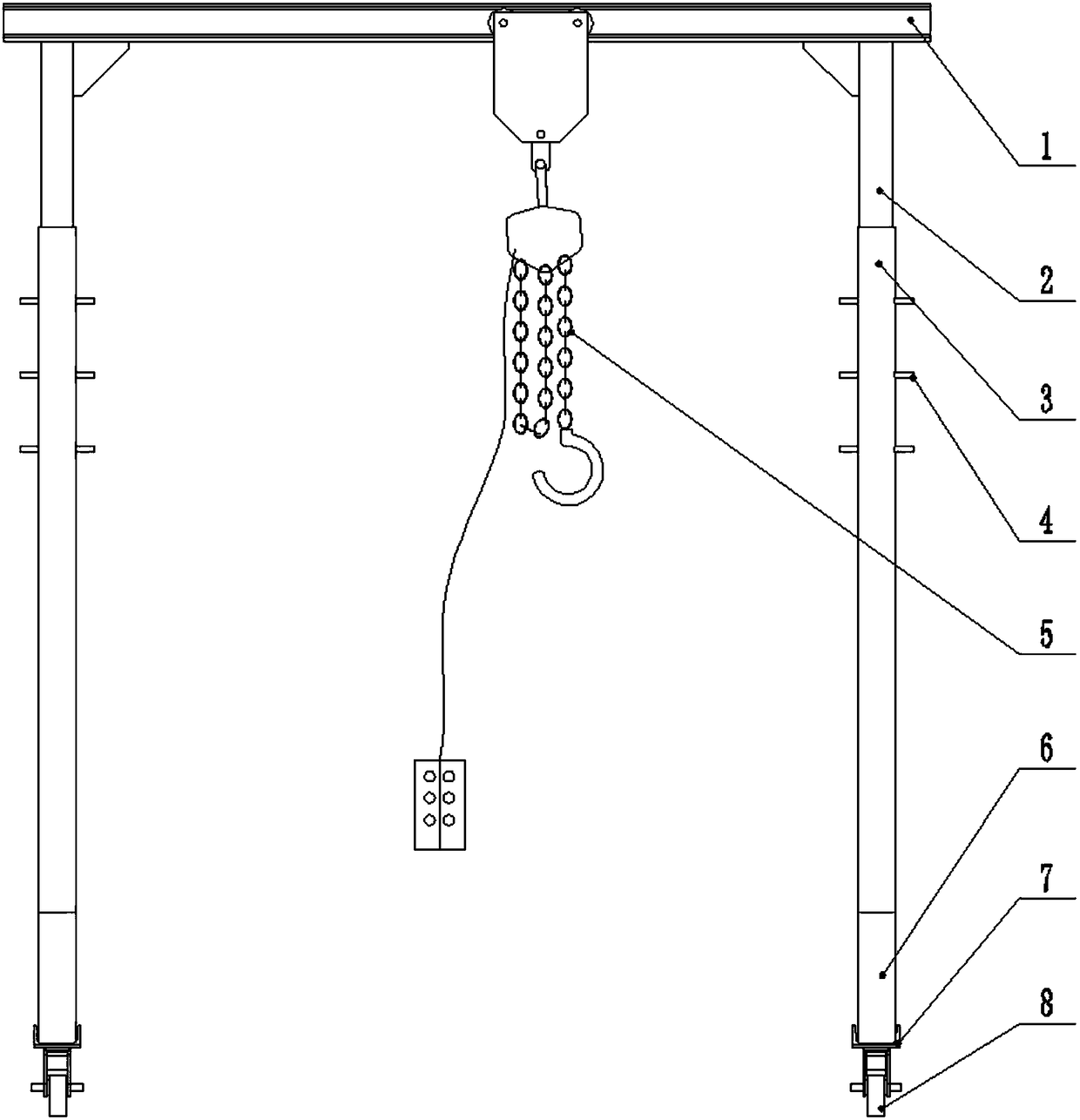

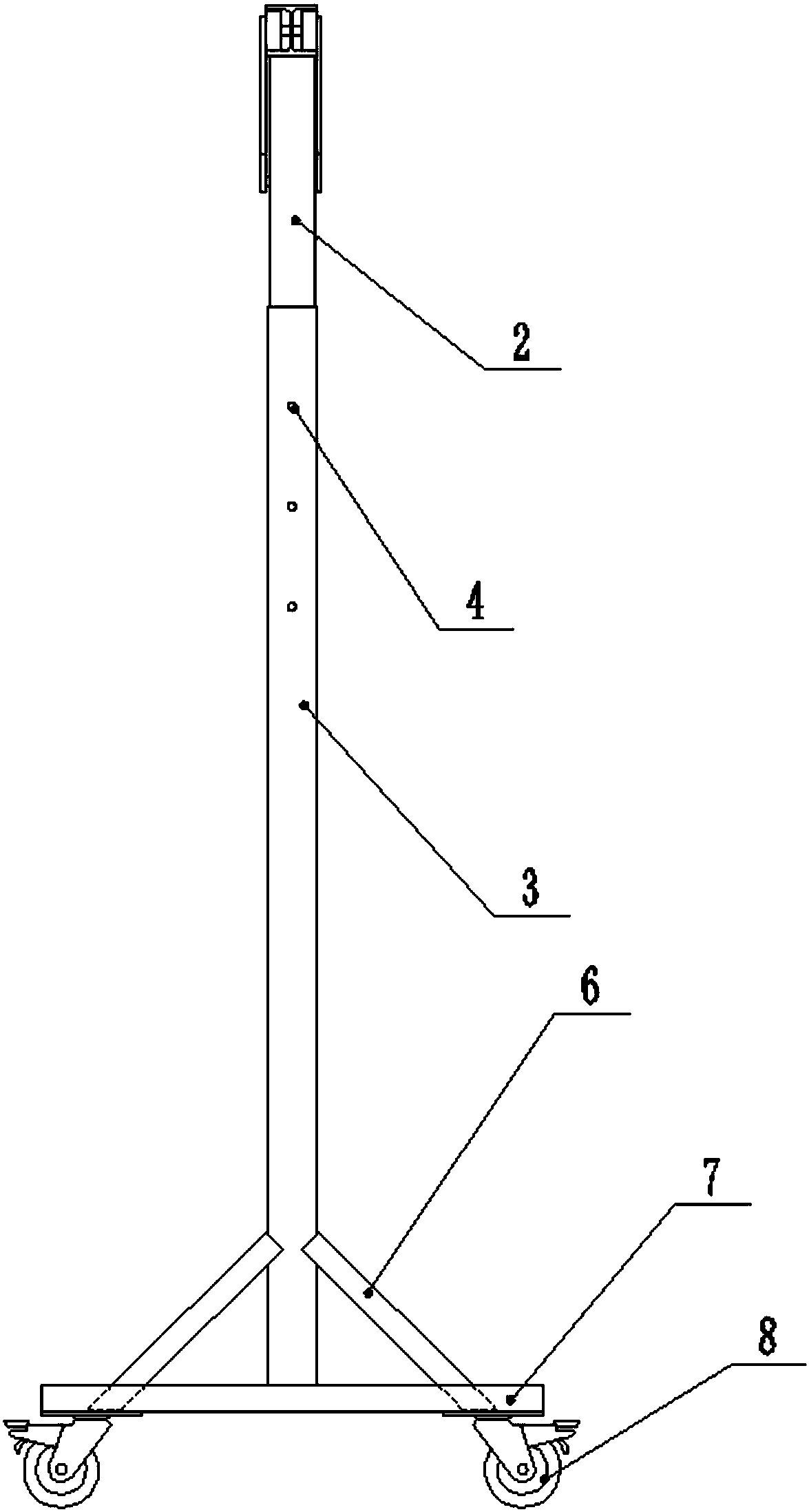

[0018] Such as Figure 1-3 The lifting frame shown in the panel cabinet of the urban rail transit power supply system is a detachable structure, which is convenient for disassembly and transportation.

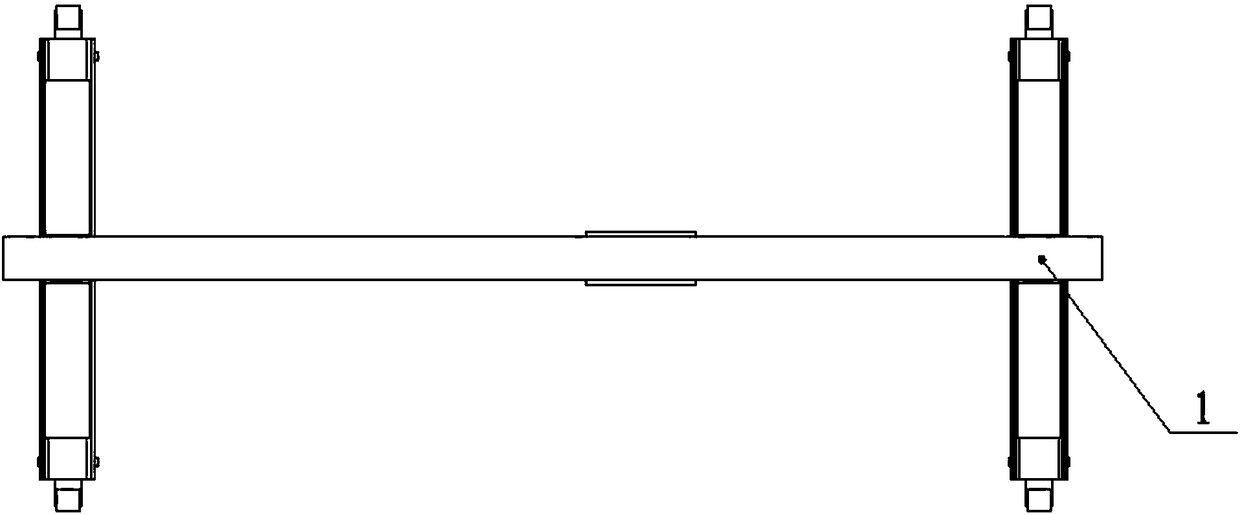

[0019] The panel cabinet installation lifting frame of the present invention comprises an I-beam 1 and a first column 2 arranged below it, the first column 2 is movably connected to the second column 3, and the first column 2 and the second column 3 are both 4 groups, and use seamless steel pipe with a thickness of 5mm.

[0020] The second column 3 is provided with a number of positioning pins 4 for height adjustment, so that the height of the lifting frame can be raised from 2500mm to 4000mm, which is suitable for various cabinets of the rail transit power supply system.

[0021] The lower part of the I-beam beam 1 is movably connected to the pulley block and the electric hoist 5. The pulley block and the electric hoist 5 adopt a bearing capacity of 2T. The efficiency of pan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com