Intelligent board feeding and discharging transfer robot

A technology for handling machines and plates, applied in the direction of manipulators, program-controlled manipulators, chucks, etc., can solve the problems of high labor costs, high production labor costs, and high labor intensity in the production of solid wood furniture, so as to reduce labor consumption and prolong service life. The effect of long life and convenient speed regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

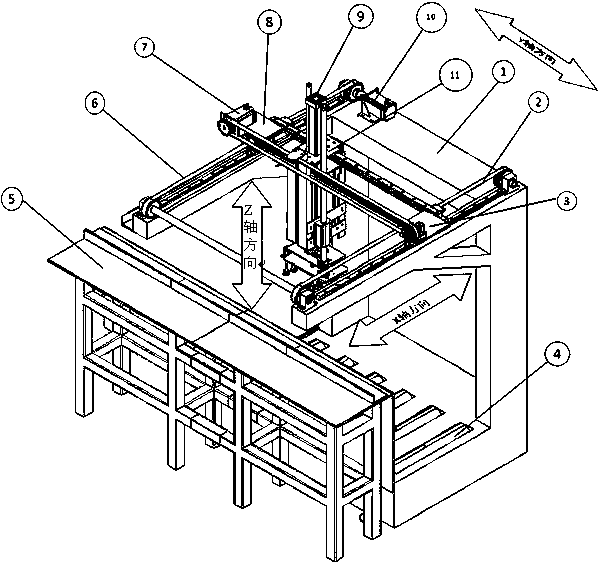

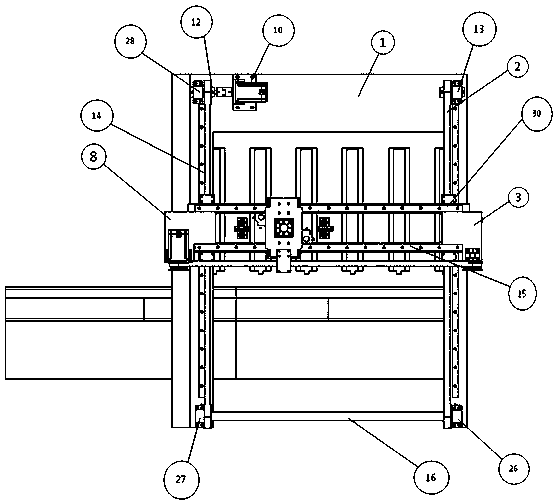

[0036] An intelligent plate loading and unloading material handling machine includes a machine 1, an X-axis motion module, a Y motion module, a suction cup assembly, and a roller frame. Frame 1 supports the operation of the modules in the three directions of X, Y, and Z. Among them, the X-axis and Y-axis are in the horizontal direction, and the Z-axis is in the vertical direction. The movements in the X-axis and Y-axis directions are respectively controlled by a Driven by a stepper motor, the Z-axis movement module is composed of a cylinder, a guide bearing and a shaft combination. The movement of the X and Y axes is driven by the stepper motor to drive the synchronous belt to pull the sliding platform to move.

[0037] The frame 1 includes a cantilever structure supporting the upper part of the frame of the three axial movements of X, Y, and Z and a support frame for installing a plurality of roller tables like the roller table 4. The two parts are integrated, and the materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com