Fabrication method of I-shaped inductor capable of surface-mounting

A technology of I-shaped inductors and manufacturing methods, which is applied in the field of inductors, can solve the problems of failure to pass environmental protection certification, huge price differences, and high product costs, and achieve the effect of meeting the requirements of automated production, increasing costs, and realizing fully automated production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

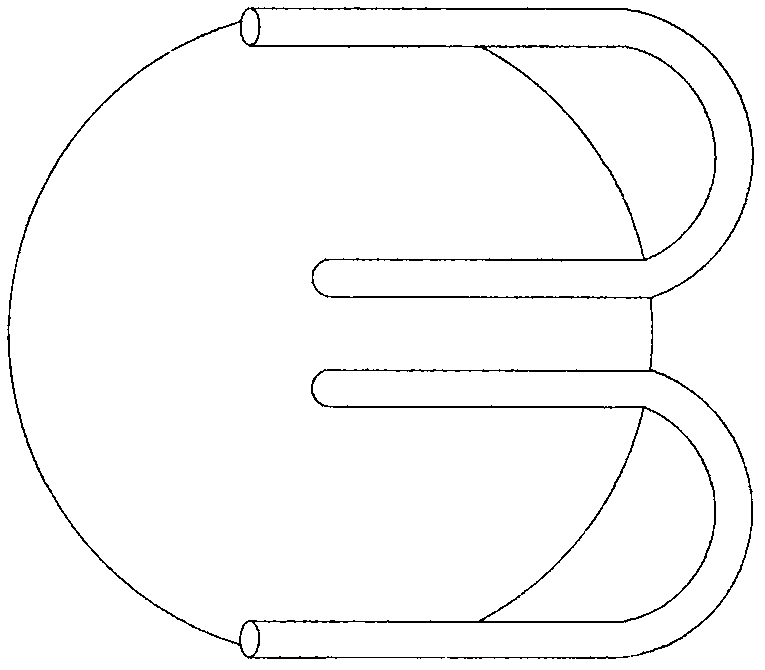

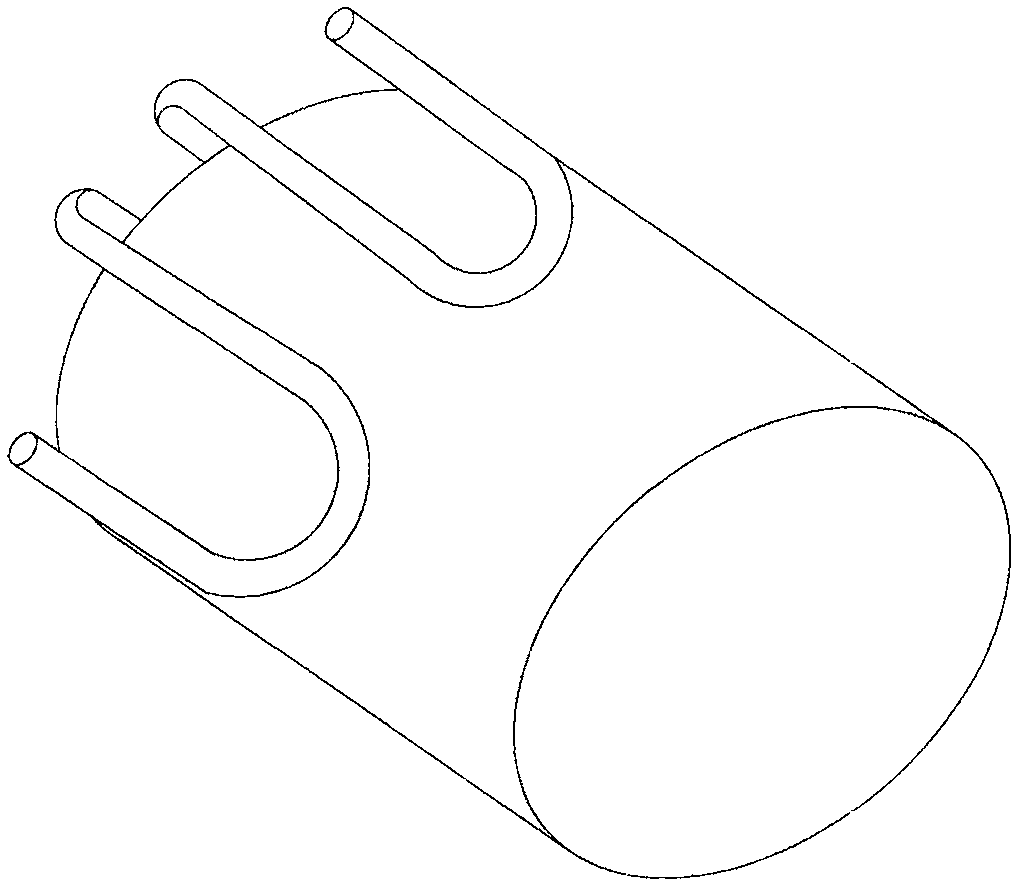

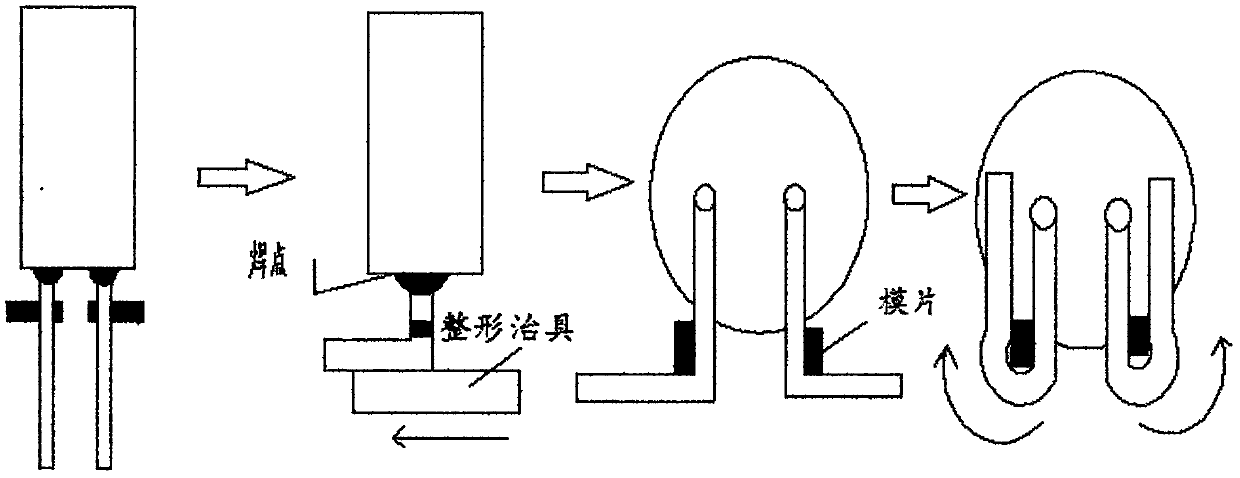

[0029] The manufacture method of the patch type vertical I-shaped inductor of the present invention, such as image 3 shown, including the following specific steps:

[0030] Step S101. Wind the nickel-zinc or magnesium-zinc ferrite vertical I-shaped inductor magnetic core with sticky pins, then soak the pins in a tin furnace at 420-450°C for 3-5 seconds, and wrap the enamelled copper wire Burn off the paint, and then stick the inductance pins with flux and dip tin in the tin furnace for 3-5 seconds, where the flux is zinc chloride solution or ethanol rosin solution or propanol rosin solution;

[0031] Step S102, encapsulating the soldered I-shaped inductor with a heat-shrinkable sleeve or with a packaging coating, wherein the heat-shrinkable sleeve is a PVC heat-shrinkable tube or a PE heat-shrinkable tube; the packaging coating is bisphenol A Type epoxy resin, novolac modified epoxy resin or aliphatic epoxy resin;

[0032] Step S103, cutting the encapsulated I-shaped induct...

Embodiment 2

[0036] The manufacturing method of the patch type horizontal I-shaped inductor of the present invention comprises the following specific steps:

[0037] Step S101, first use the DR cutting machine to cut the wire groove of the rod-shaped iron powder core with pinholes, and then coat the cut I-shaped iron powder core with epoxy resin coating for insulation treatment ;Insulate the vertical I-shaped iron powder core core with pins and wires, then soak the pins in a tin furnace at 420-450°C for 2-3 seconds to burn off the paint skin of the enamelled copper wire, Then stick the inductance pins with flux and dip tin in the tin furnace for 2-3 seconds, where the flux is zinc chloride solution or ethanol rosin solution or propanol rosin solution;

[0038] Step S102, encapsulating the soldered I-shaped inductor with a heat-shrinkable sleeve or with a packaging coating, wherein the heat-shrinkable sleeve is a PVC heat-shrinkable tube or a PE heat-shrinkable tube; the packaging coating i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com