Vortex pump with separation net for enhancing self-absorption

A technology of separating net and vortex pump, which is applied to the components, pump, driving pump, etc. of the pumping device for elastic fluid, can solve the problem that the vortex pump cannot work normally, reduce the self-priming capacity, and affect the self-priming capacity of the self-priming pump. and other problems, to achieve the effect of broad prospects for technology promotion and industrialization, improvement of self-priming height and speed, and low difficulty in processing and manufacturing processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

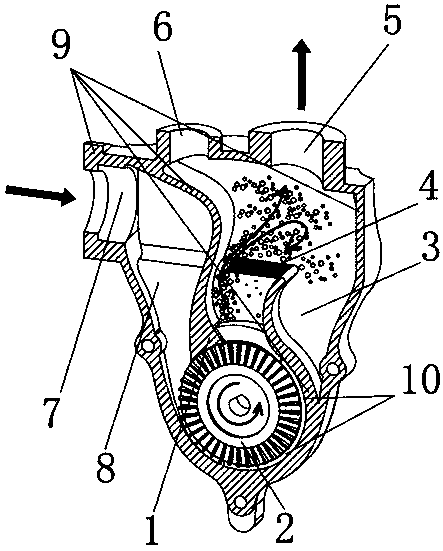

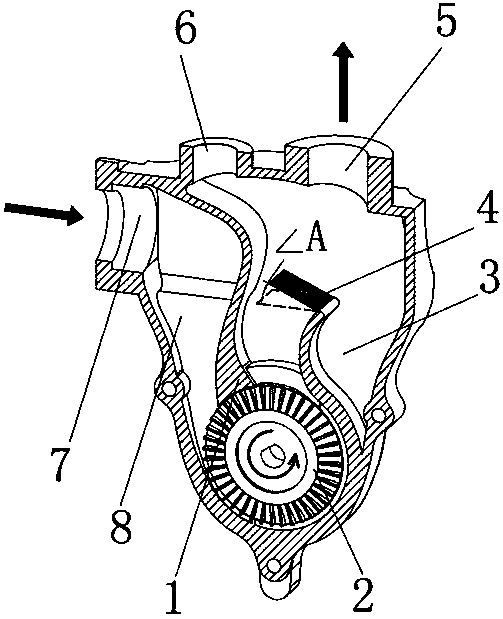

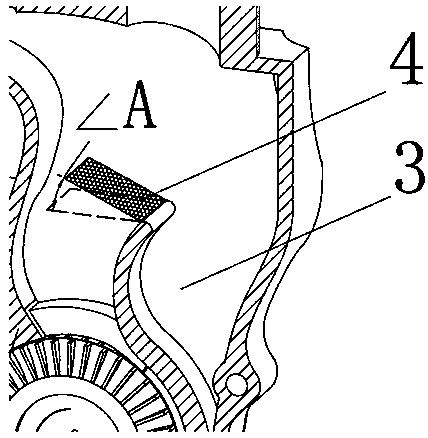

[0029] Such as figure 1 As shown, the enhanced self-priming vortex pump of this embodiment includes a vortex pump pump body 9 and a separation net 4, the separation net is arranged in the gas-liquid separation chamber 3, close to the outlet of the vortex pump pressure water chamber and the partition tongue 1, with a certain The angle A and the area S can effectively separate the gas-liquid two-phase fluid in the gas-liquid separation chamber 3 and return to the area near the impeller 2. At the same time, the separation net 4 is used to rectify the return fluid, decelerate and pressurize, and improve the efficiency of the return fluid. The pressure potential energy and flow uniformity greatly reduce the gas content of the return fluid flowing back to the water absorption chamber 8 through the partition tongue 1, so that the pressure potential energy of the return fluid is higher, so that the gas-liquid mixing in the water absorption chamber 8-gas-liquid separation chamber 3 Gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com