Mute high-speed pipe-interior pump and complete-set pressurizing device

A pump-in-pipe, high-speed technology, applied in pump devices, valve devices, components of pumping devices for elastic fluids, etc. and vibration increase to achieve the effect of reducing vibration, ensuring high speed and reducing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

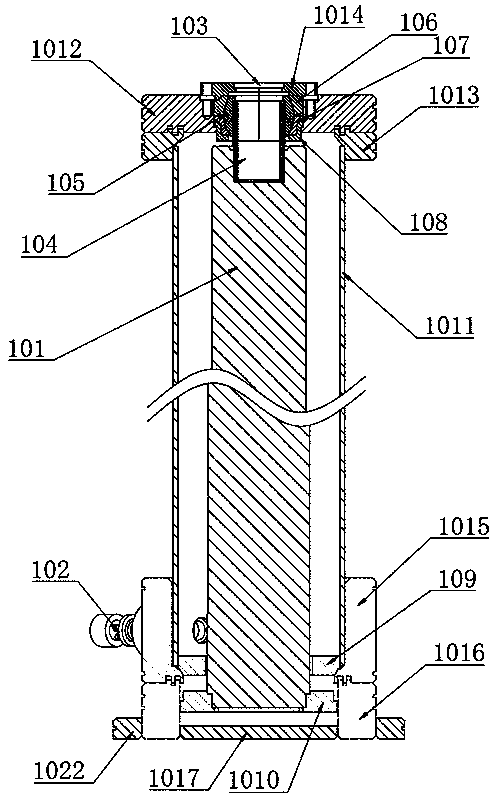

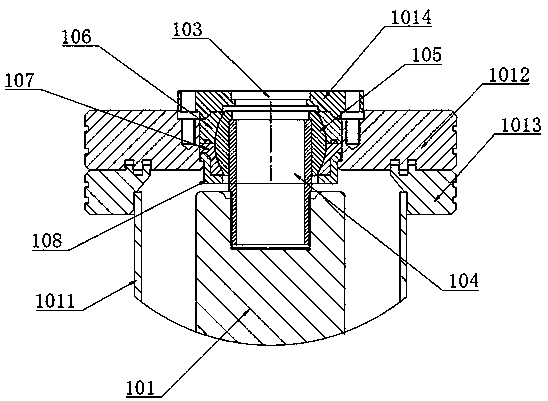

[0057] Embodiment 1: as figure 1 and figure 2 As shown, a silent high-speed pipe pump includes a pump casing and a submersible pump 101, the side of the pump casing is provided with a water inlet 102, and the top of the pump casing is provided with a water outlet 103, and the submersible pump 101 is installed on In the pump casing, the top of the submersible pump 101 is provided with a positioning shaft 104, the positioning shaft 105 is provided with a positioning shaft through hole, and the positioning shaft through hole is connected with the submersible pump 101, and the upper end of the pump casing is provided with The first positioning seat, the lower end of the pump casing is provided with a second positioning seat, the first positioning seat includes a ball bowl and a ball head 105, the ball bowl is connected with the pump casing around, and the ball head 105 is installed on the ball In the bowl, the ball head 105 is provided with a vertical through hole, the positioni...

Embodiment 2

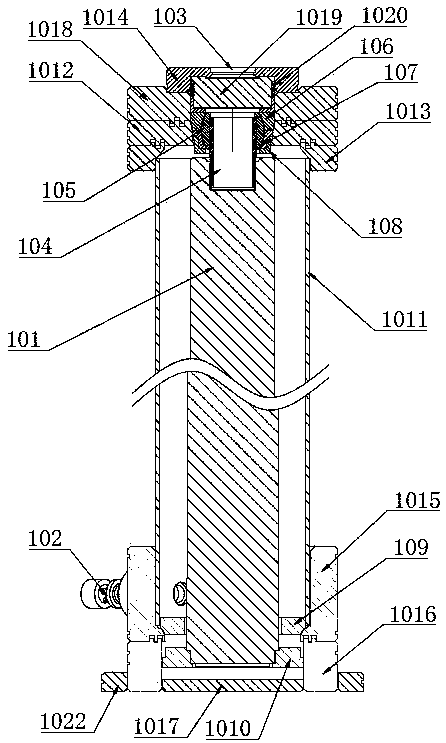

[0063] Embodiment 2: As a kind of improved scheme of embodiment 1, such as Figure 3 to Figure 10As shown, a third top flange 1018 is also provided between the top cover plate 1014 and the first top flange 1012, and a third ring is provided between the first top flange 1012 and the third top flange 1018. shaped tongue and groove structure, a check valve 1019 is installed in the flange hole of the third top flange 1018, and a side wall flange 2014 is provided on the valve seat side wall 2012 of the check valve 1019, and the side wall The flexible seal 1020 and the first sealing thrust seat 1021 are sequentially sleeved under the flange 2014. The first sealing thrust seat 1021 includes a thrust side plate and a thrust bottom plate. The upper end of the thrust side plate is connected to the flexible seal 1020. connection, the upper surface of the thrust bottom plate is connected with the check valve 1019, the lower surface of the thrust bottom plate is connected with the upper se...

Embodiment 3

[0068] Embodiment 3: as Figure 11 and Figure 12 As shown, a complete booster device includes a mounting plate 1028 and four silent high-speed pipe pumps, and the four silent high-speed pipe pumps are all installed on the mounting plate 1028, and the four silent high-speed pipe pumps are respectively The first silent high-speed pipe pump 1023, the second silent high-speed pipe pump 1025, the third silent high-speed pipe pump 1024 and the fourth silent high-speed pipe pump 1026, the first silent high-speed pipe pump 1023 and the second The pumps in the quiet high-speed pipe 1025 are connected in series to form a first pump group, and the pumps 1024 in the third quiet high-speed pipe and the pump 1026 in the fourth quiet high-speed pipe are connected in series to form a second pump group. The first pump group and the second pump group in parallel.

[0069] In this embodiment, the first silent high-speed pipe pump 1023 and the third silent high-speed pipe pump 1024 select the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com