Prefabricated column and beam connection structure and method of prefabricated building frame structure

A technology of frame structure and connection method, which is applied in the direction of building structure and construction, can solve the problems of high rigidity in the joint area, inconvenient production, damage, etc., and achieve the effect of reasonable disassembly and assembly and improvement of construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

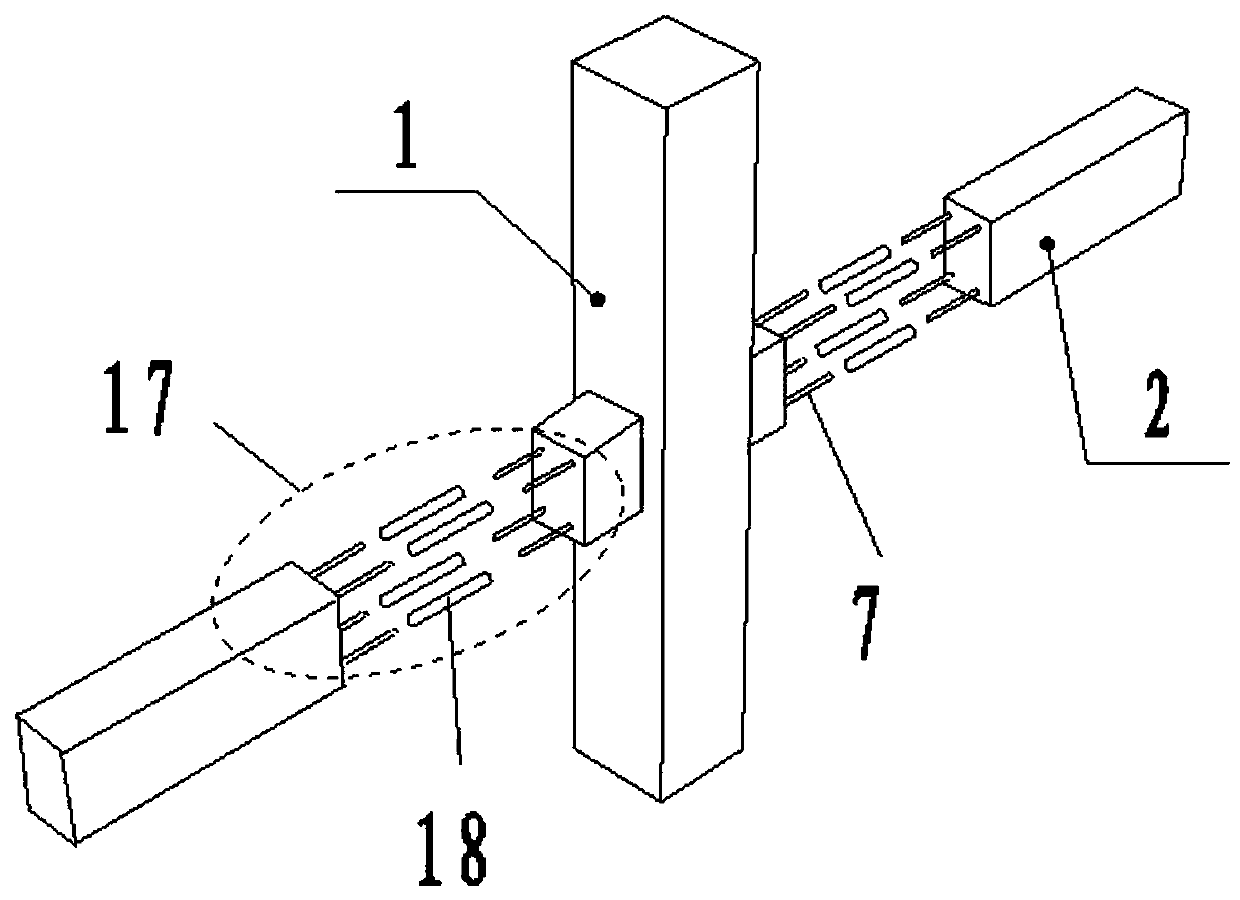

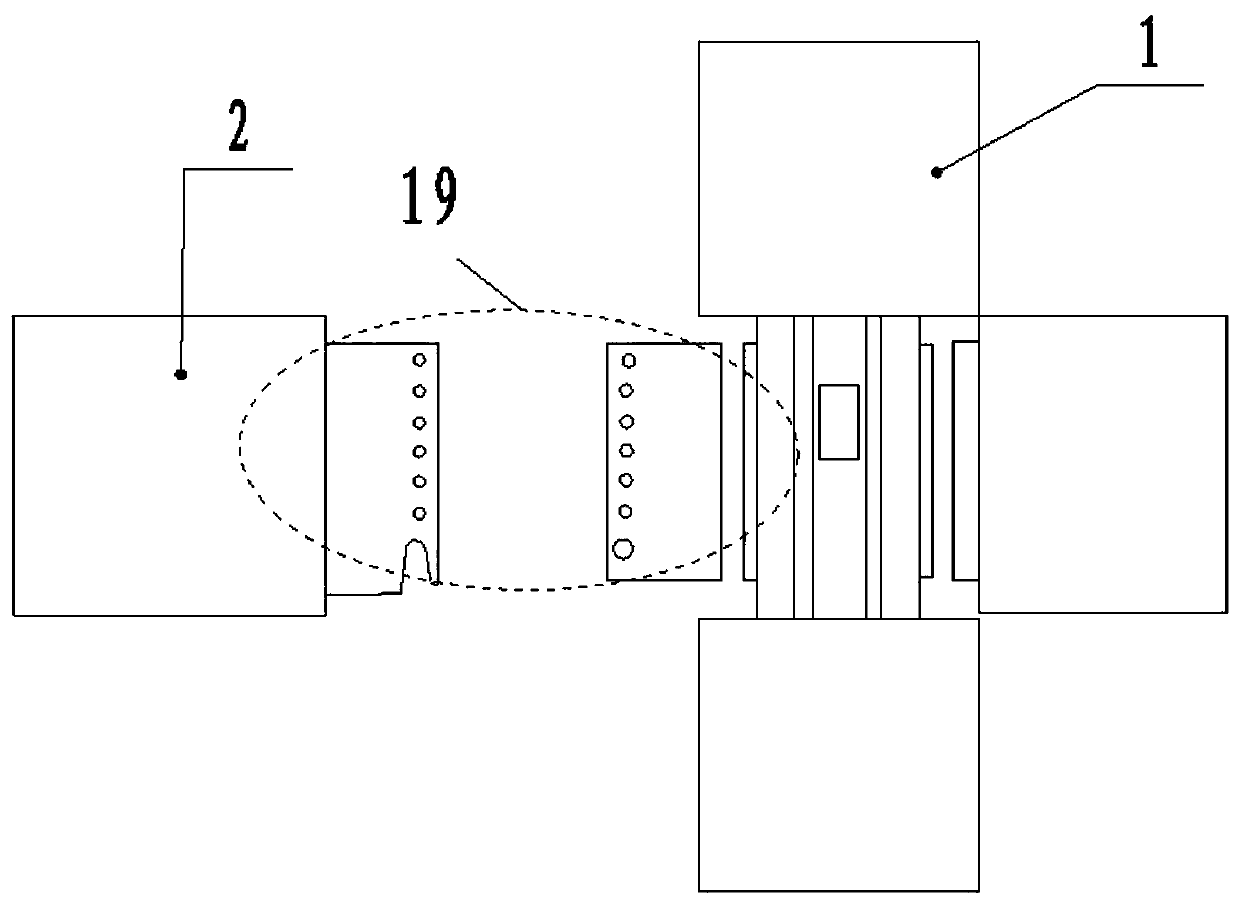

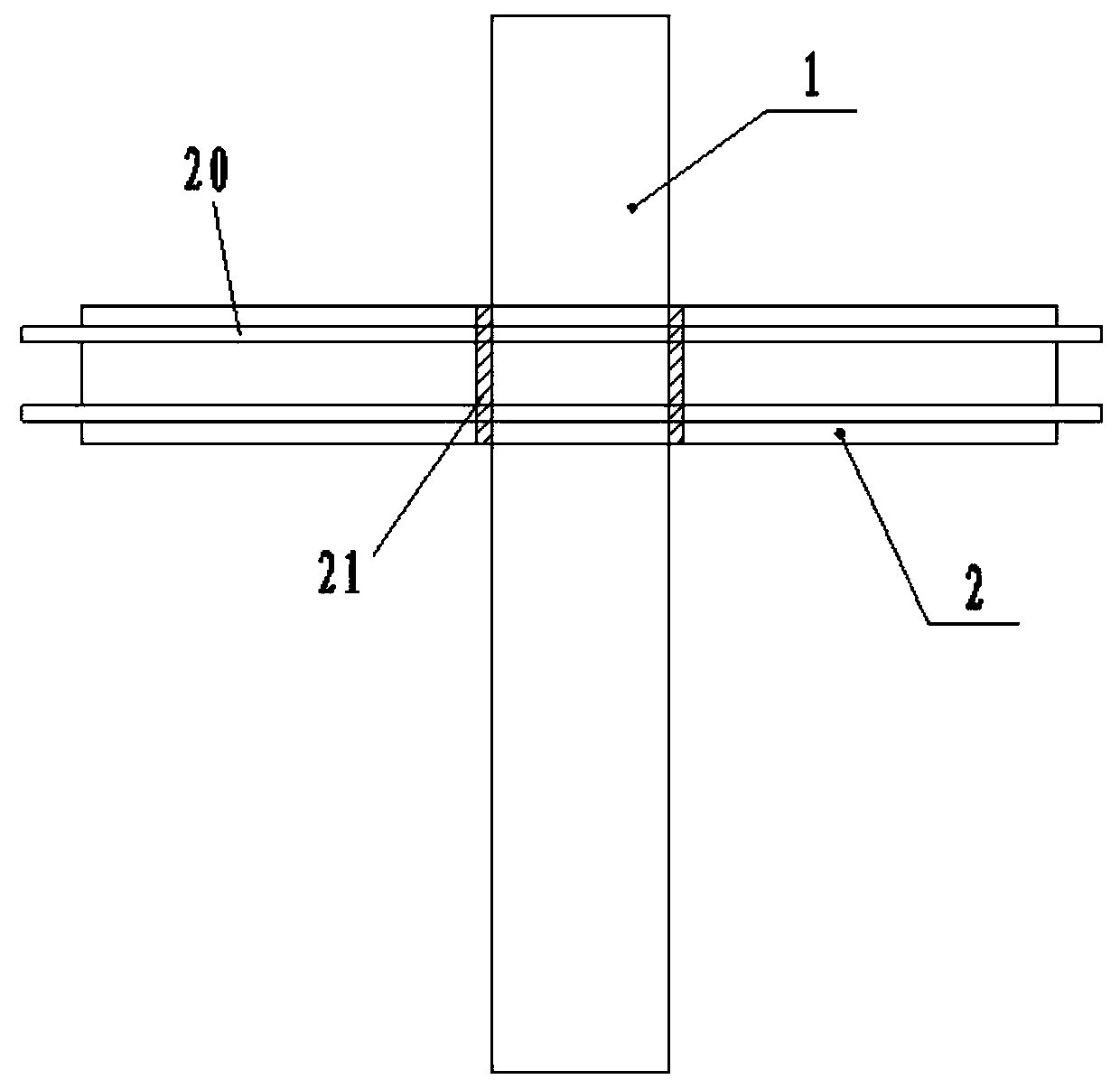

[0076] Such as Figure 4-22 As shown, a prefabricated column and prefabricated beam connecting structure of a prefabricated building frame structure of the present invention includes a prefabricated column 1 and a prefabricated beam 2. The prefabricated column 1 and the prefabricated beam 2 are made of reinforced concrete, and the prefabricated column 1 is surrounded by There is at least one dark corbel section 3, the precast column 1 and the dark corbel section 3 are cast in one piece, such as Figure 6-8 As shown, the prefabricated column 1 surrounds the four dark corbel sections 3 as a prefabricated center column, which is arranged on the frame (such as Picture 10 As shown in the middle part, the prefabricated column 1 surrounds the three dark corbel sections 3 is a prefabricated side column, which is set in the frame (such as Picture 10 (Shown), the prefabricated column 1 surrounds the two dark corbel sections 3 is a prefabricated corner column, set in the frame (such as Pi...

Embodiment 2

[0086] Such as Figure 4-22 As shown, the present invention is a prefabricated column and prefabricated beam connection structure of a prefabricated building frame structure. The prefabricated column 1 is embedded with prefabricated column reinforcing ribs 22, and at least one end of the prefabricated column 1 is provided with a prefabricated Column steel plate 23, the prefabricated column steel plate 23 is connected to the prefabricated column reinforcement 22, and connecting through holes 24 are evenly distributed on the ring surface of the prefabricated column steel plate 23. Bolt connection installation groove 25. When two prefabricated columns 1 need to be connected, after the prefabricated column steel plates 23 at the ends of the two prefabricated columns 1 are connected, they are installed in the connecting through holes 24 through bolts 26 to realize the connection of the two prefabricated columns 1 connection. After the installation and connection are completed, the b...

Embodiment 3

[0088] Such as Figure 4-22 As shown, a method for connecting prefabricated columns and prefabricated beams of a prefabricated building frame structure of the present invention includes the steps:

[0089] The prefabricated component composed of the prefabricated column 1 and the dark corbel section 3 is integrally poured in the prefabricated component factory, and the prefabricated column 1 and the dark corbel section 3 are integrally poured;

[0090] Pouring the precast beam 2; the precast beam 2 is lapped on the precast beam lap joint 5 of the dark corbel section 3 on the two precast columns 1 through the corbel section lap joints 8 at both ends, and the corbel section lap joint 8 is overlapped with the precast beam After the joint 5 is lapped, the corbel connecting steel plate 9 on the corbel section lap joint 8 is connected with the precast beam connecting steel plate 6 on the precast beam lap joint 5.

[0091] The pouring of the dark corbel section includes the following steps:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com