Splicing structure and splicing method of prefabricated bridge piers and prefabricated bearing platform

A technology of prefabricated caps and bridge piers, which is applied in the direction of basic structure engineering, bridges, bridge parts, etc., can solve the problems of construction quality affected by the overall quality of workers, easily affected by weather and natural environment, and the quality of cast-in-place is difficult to guarantee, etc., to achieve convenience The effects of on-site operation, shortened construction period, and improved splicing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

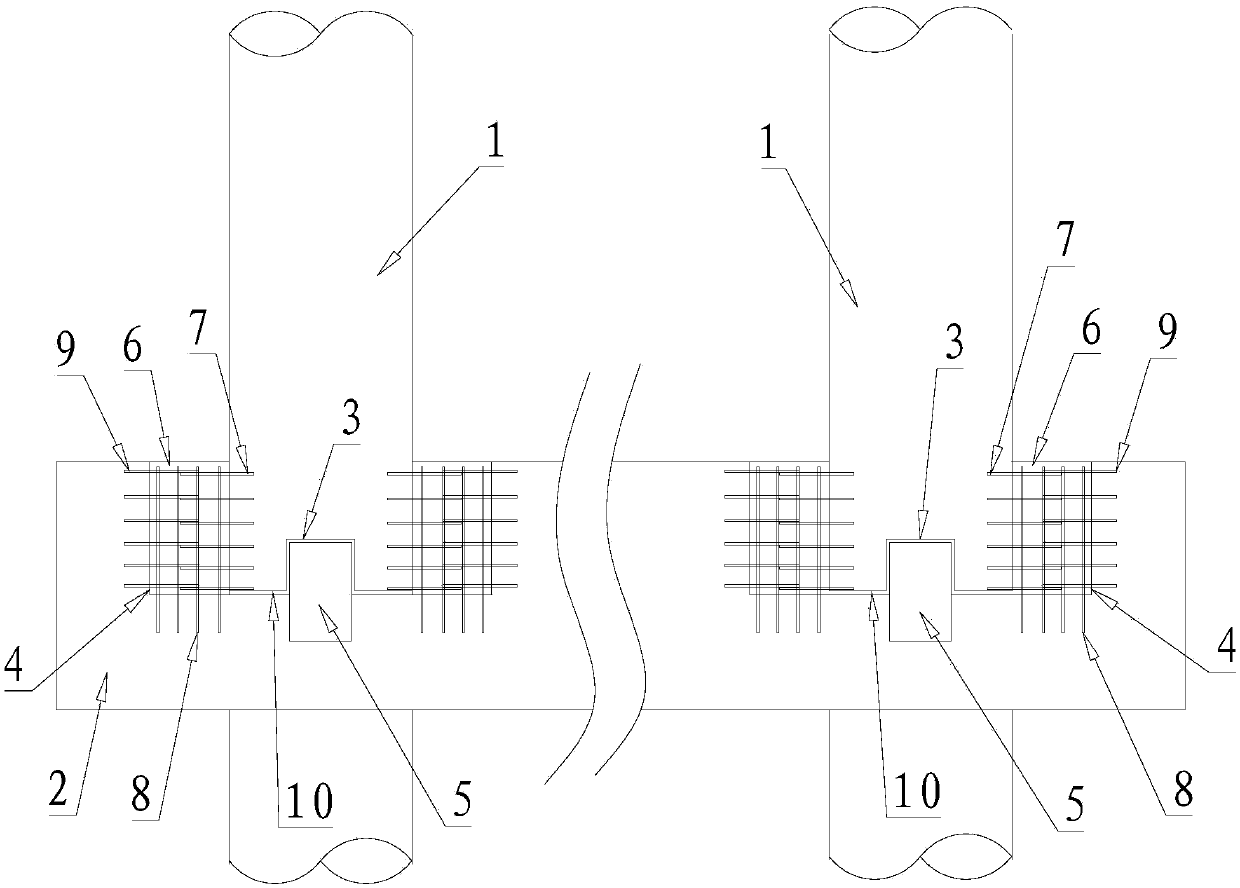

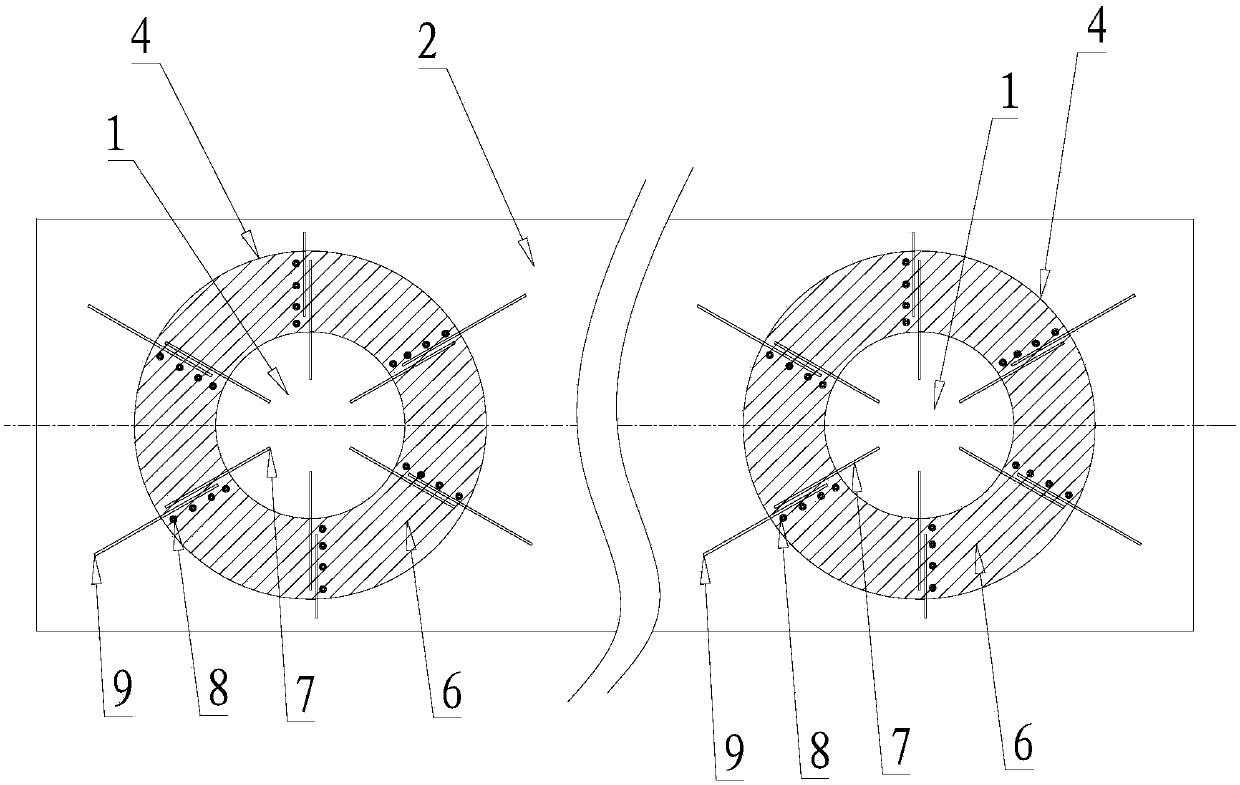

[0048] Please refer to Figure 1 to Figure 2 Shown, embodiment one of the present invention is:

[0049] A splicing structure of a prefabricated pier and a prefabricated cap, comprising a prefabricated pier 1 and a prefabricated cap 2; a cylindrical first groove is provided at the center of the bottom of the prefabricated pier 1, and inside the first groove is a Hollow steel pipe 3, the hollow steel pipe 3 is attached to the inner wall of the first groove; the top of the prefabricated platform 2 is provided with an annular groove 4, and the inner wall of the annular groove 4 is surrounded by the hollow steel 3 Concrete-filled steel pipe tenon 5 matching the pipe; the prefabricated bridge pier 1 cooperates with the concrete-filled steel pipe tenon 5 through the hollow steel pipe 3 , and the bottom surface of the prefabricated bridge pier 1 fits with the groove bottom of the annular groove 4 ; The gap between the outer wall of the annular groove 4 and the outer wall of the pref...

Embodiment 2

[0057] The difference between the second embodiment and the first embodiment is that the number of the reinforced steel bar assemblies is four and distributed evenly along the circumference of the prefabricated pier.

Embodiment 3

[0059] The difference between the third embodiment and the first embodiment is that the number of the reinforced steel bar assemblies is eight and distributed evenly along the circumference of the prefabricated bridge pier. In this embodiment, eight reinforcing steel bar assemblies uniformly distributed along the circumference of the prefabricated bridge pier are used, compared with the use of four reinforcing steel bar assemblies in Embodiment 2, the strengthening effect on the joint of the prefabricated bridge pier and the prefabricated cap is better.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com