Reaction device and method for preparing mandelic acid compounds

A reaction device and compound technology, which are applied in the field of reaction devices for preparing mandelic acid compounds, can solve the problems of no obvious technical effect, unsatisfactory implementation effect, easy stratification or crystallization, etc., and achieve high mass transfer and heat transfer efficiency, Effect of short reaction time and reduction of side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

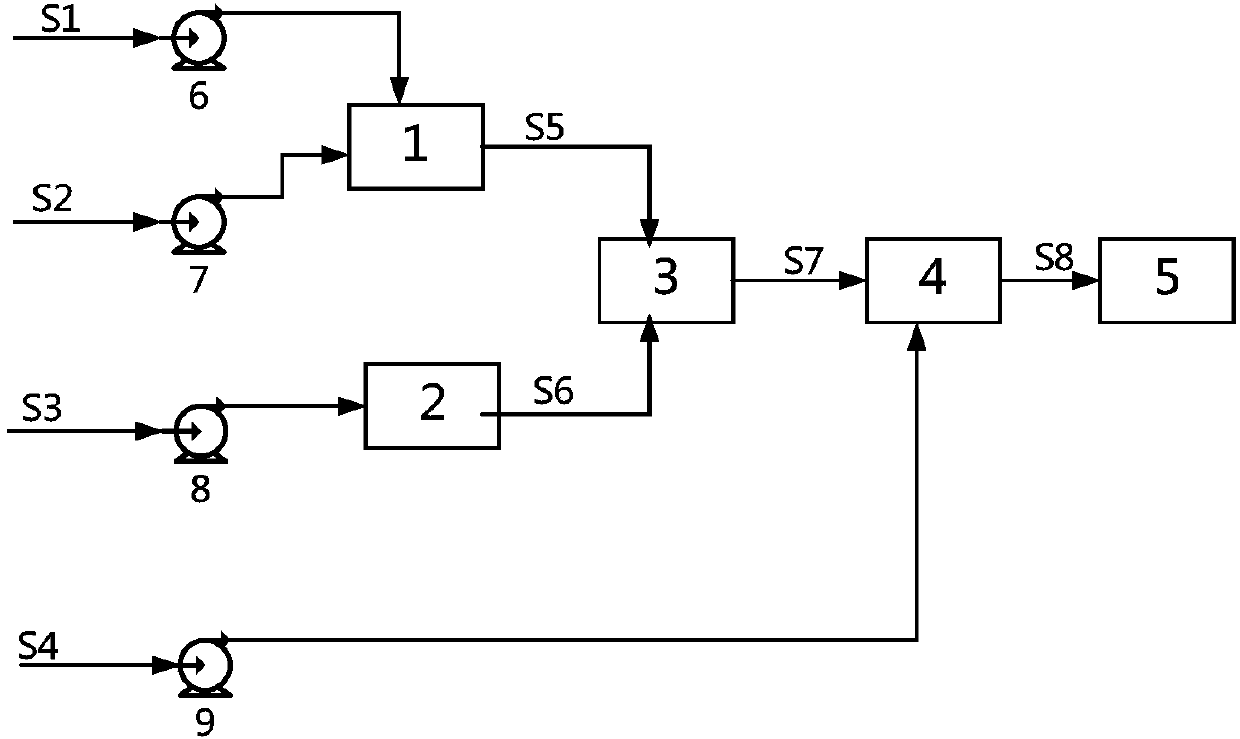

[0064] A reaction device for preparing mandelic acid compounds, comprising the first microchannel heat exchanger 1 (high-throughput microchannel heat exchanger, available from Corning, model G1, consisting of a microchannel template), the second microchannel Heat exchanger 2 (high-throughput microchannel heat exchanger, available from Corning, model G1, consisting of a microchannel template), the first microchannel reactor 3 (high-throughput microchannel reactor, available from Corning, The model is G1, consisting of a microchannel reaction template), the second microchannel reactor 4 (high-throughput microchannel reactor, purchased from Corning, the model is G1, consisting of a microchannel reaction template), product collector 5 , the first liquid metering pump 6, the second liquid metering pump 7, the third liquid metering pump 8, the fourth liquid metering pump 9, the outlet of the first liquid metering pump 6 and the first inlet of the first microchannel heat exchanger 1 ...

Embodiment 2

[0067] A reaction device for preparing mandelic acid compounds, comprising the first microchannel heat exchanger 1 (high-throughput microchannel heat exchanger, available from Corning, model G1, consisting of a microchannel template), the second microchannel Heat exchanger 2 (high-throughput microchannel heat exchanger, available from Corning, model G1, consisting of a microchannel template), the first microchannel reactor 3 (high-throughput microchannel reactor, available from Corning, Model is G1, is made up of two microchannel reaction modules connected in series), the second microchannel reactor 4 (high-throughput microchannel reactor, purchased from Corning, model is G1, is made up of a microchannel reaction template), product Collector 5, the first liquid metering pump 6, the second liquid metering pump 7, the third liquid metering pump 8, the fourth liquid metering pump 9, the outlet of the first liquid metering pump 6 and the outlet of the first microchannel heat exchan...

Embodiment 3

[0070]A reaction device for preparing mandelic acid compounds, comprising the first microchannel heat exchanger 1 (high-throughput microchannel heat exchanger, available from Corning, model G1, consisting of a microchannel template), the second microchannel Heat exchanger 2 (high-throughput microchannel heat exchanger, available from Corning, model G1, consisting of a microchannel template), the first microchannel reactor 3 (high-throughput microchannel reactor, available from Corning, Model is G1, is made up of three microchannel reaction modules connected in series), the second microchannel reactor 4 (high-throughput microchannel reactor, purchased from Corning, model is G1, is made up of a microchannel reaction template), product Collector 5, the first liquid metering pump 6, the second liquid metering pump 7, the third liquid metering pump 8, the fourth liquid metering pump 9, the outlet of the first liquid metering pump 6 and the outlet of the first microchannel heat excha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com