Geopolymer and preparation method and application thereof

A technology of geopolymers and mixtures, applied in cement production and other directions, can solve the problem of difficult resource utilization of shield slag with high mud content, and achieve the effects of avoiding carbon emissions, reducing porosity, and improving durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

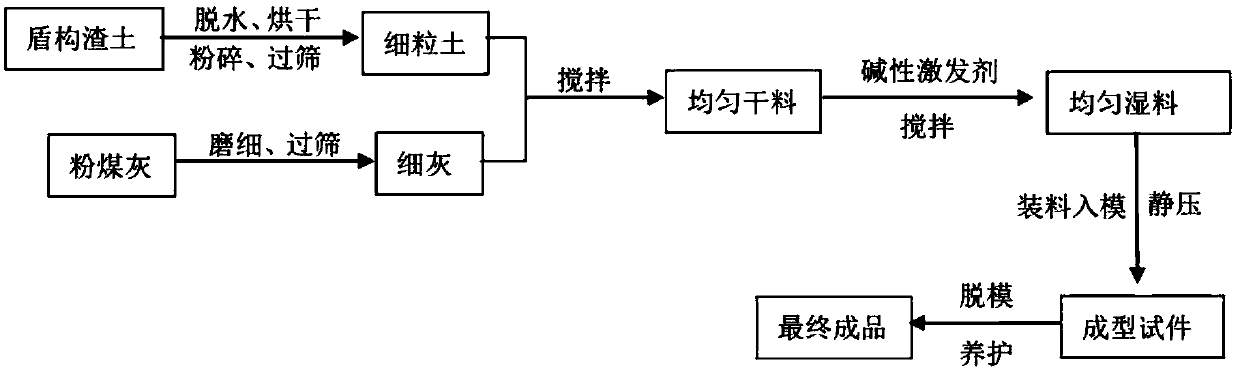

[0061] As a general inventive concept, the present invention also provides the preparation method of above-mentioned geological polymer, comprises the following steps:

[0062] (1) drying and pulverizing the shield machine dregs to obtain processed shield machine dregs; mixing the processed shield machine dregs with fly ash in proportion to obtain a mixture;

[0063] (2) Add the basic activator to the mixture in step (1) by spraying, and stir to obtain the mixed wet material;

[0064] (3) Put the mixed wet material obtained in the step (2) into a mold and press it tightly, and release the mold after standing to obtain the geopolymer.

[0065] In the above step (1), after mixing the shield dreg obtained by drying and pulverizing with the fly ash in proportion, dry mixing for 5 minutes, and mixing evenly to obtain a mixture.

[0066] The above-mentioned preparation method of the geopolymer utilizes the high mud content shield dregs as resources, not only digests the shield dreg...

Embodiment 1

[0079] The geopolymer is prepared from the following raw materials: dried, pulverized and screened shield dregs and fly ash with a particle size of less than 2mm and a moisture content of less than 3% in a mass ratio of 3:1 Mix to form a mixture, the mass ratio of the basic activator and the mixture is 0.14: 1, wherein the basic activator is a mixed solution of water glass and NaOH solution, the mass ratio of water glass solution and NaOH solution is 1.8: 1, the concentration of NaOH 8mol / L, water glass modulus 3.0. The shield muck mentioned above is shield muck with high mud content, and its main component is clay.

[0080] The preparation method of above-mentioned geopolymer is as follows:

[0081] (1) Dry the high mud content shield dregs, then pulverize them, and pass through a 2mm sieve to obtain shield dregs with a particle size less than 2mm, i.e. fine-grained soil; grind the dry fly ash into fine powder, And pass through a 2mm sieve to obtain fly ash with a particle ...

Embodiment 2

[0084] The geopolymer is prepared from the following raw materials: dried, pulverized and screened shield dregs and fly ash with a particle size of less than 2mm and a moisture content of less than 3% in a mass ratio of 3:1 Mix to form a mixture, the mass ratio of the basic activator to the mixture is 0.16: 1, wherein the basic activator is the mixed solution of water glass and NaOH solution, the mass ratio of water glass solution and NaOH solution is 2: 1, the concentration of NaOH 10mol / L, water glass modulus 3.0. The shield muck mentioned above is shield muck with high mud content, and its main component is clay.

[0085] The method for preparing the geopolymer in this embodiment is the same as that in Embodiment 1.

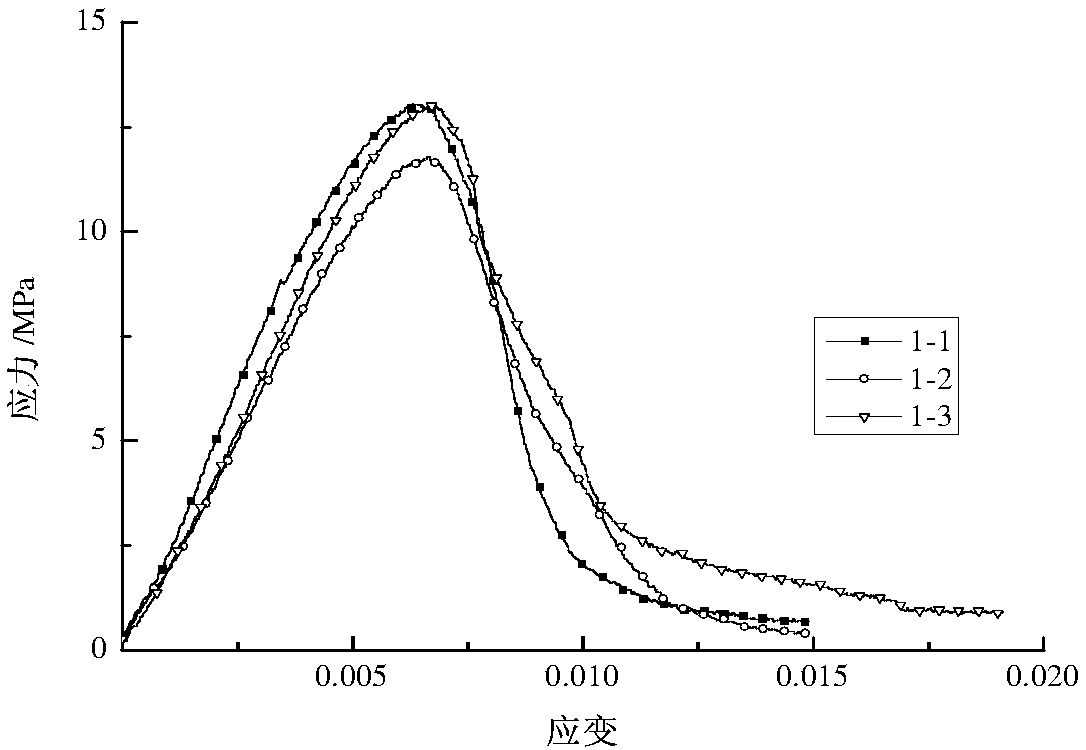

[0086]The end faces of the above-mentioned geopolymer specimens were ground to be smooth, and the Instron rigidity testing machine was used to carry out uniaxial compression experiments, and the full stress-strain curves were measured. Figure 4 , the peak c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com