4D admixture for well cementation

A technology of external admixture and cementing, which is applied in drilling compositions, chemical instruments and methods, etc., to achieve the effects of reducing cementing costs, stabilizing system performance, and reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] A 4D external admixture for well cementing is characterized by:

[0032] (1) A 4D external admixture for well cementing is composed of 70% of special low-density materials (floating beads, fly ash), 10% of stabilizer (micro silicon), 10% of reinforcing agent (slag), modifier ( CaO) 10% composition;

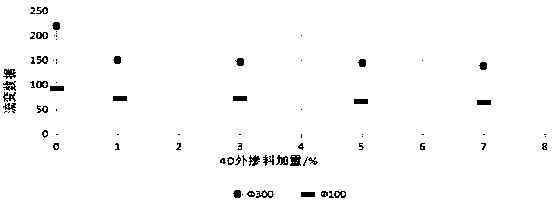

[0033] (2) A 4D external admixture for well cementing can be well mixed with cement, and the performance of the formed system is temperature resistance, acid resistance, and corrosion resistance, which can better meet the requirements of cementing (see Table 1; Figure 1-4 );

[0034] (3) A 4D external admixture for well cementing is mixed with cementing cement in a certain proportion to form a new cement slurry system, which is applied to low-pressure, easy-to-seep and leaky wells. The system is relatively stable. The prepared cement slurry has anti-channeling, High toughness and other characteristics (see Table 2, 3; Figure 5-6 );

[0035] (4) The application of a 4D ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com