Calcium carbonate preparation method for accelerating carbonatation reaction

A technology of carbonation and calcium carbonate, applied in calcium carbonate/strontium/barium, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of long reaction time of calcium carbonate, uneven product quality, acceleration, etc., and achieve uniform and stable quality , Accelerate the carbonation reaction rate, the effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

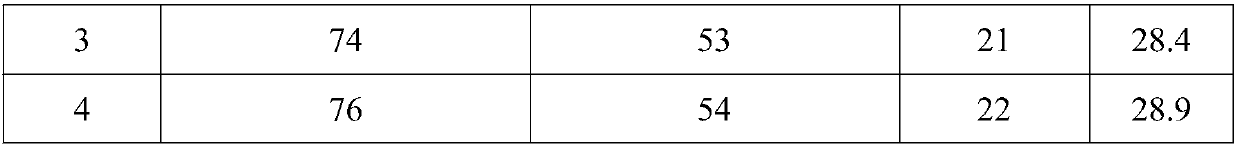

Embodiment 1

[0020] Improved carbonation reactor:

[0021] Improved coating of carbon dioxide adsorbent materials in a stirred batch bubbling carbonation reactor. A layer of glue with a thickness of 3mm is evenly coated on the inner wall of the reaction kettle, and the silica powder with carbon dioxide adsorption properties is evenly sprayed on the surface of the glue before the glue is dried and solidified, so that the silica is evenly attached to the surface of the glue. The silicon dioxide fixed on the surface can be used after the glue dries. The average specific surface area of silica is 379m 2 / g, the average pore diameter of the silica channel is 5nm.

Embodiment 2

[0023] Improved carbonation reactor:

[0024] Coating improvements for carbon dioxide adsorbent materials in high-gravity carbonation reactors. In parts by weight, mix 1 part of silica gel powder with carbon dioxide adsorption performance with 5 parts of paint, and then coat the inner wall of the high-gravity carbonation reaction kettle, and use it after the coating material is completely dry; the carbon dioxide adsorption The average specific surface area of the material is 263m 2 / g, the average pore diameter of the pores of the carbon dioxide adsorbing material is 8nm.

Embodiment 3

[0026] Improved carbonation reactor:

[0027] Improved coating of carbon dioxide adsorbent materials in a stirred batch bubbling carbonation reactor. Evenly coat a layer of glue with a thickness of 1mm on the inner wall of the reaction kettle. Before the glue is dried and solidified, evenly spray silica and aluminosilicate powder with carbon dioxide adsorption properties on the surface of the glue to make the silica and aluminosilicate powder Evenly attached to the glue surface. The silicon dioxide and aluminosilicate powders fixed on the surface by the glue can be used; the average specific surface area of the carbon dioxide adsorption material is 86m 2 / g, and the average pore diameter of the pores of the carbon dioxide adsorbing material is 19 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average specific surface area | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Average specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com