Carbon roasting furnace smoke pollutant heat storage incineration furnace and treatment method thereof

A carbon roasting furnace and pollutant technology, which is applied in waste heat treatment, combustion methods, heat storage equipment, etc., can solve the problems of energy waste, explosion, and high cost, and achieve the effect of avoiding temporary discharge, maintaining stability, and reducing fluctuations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

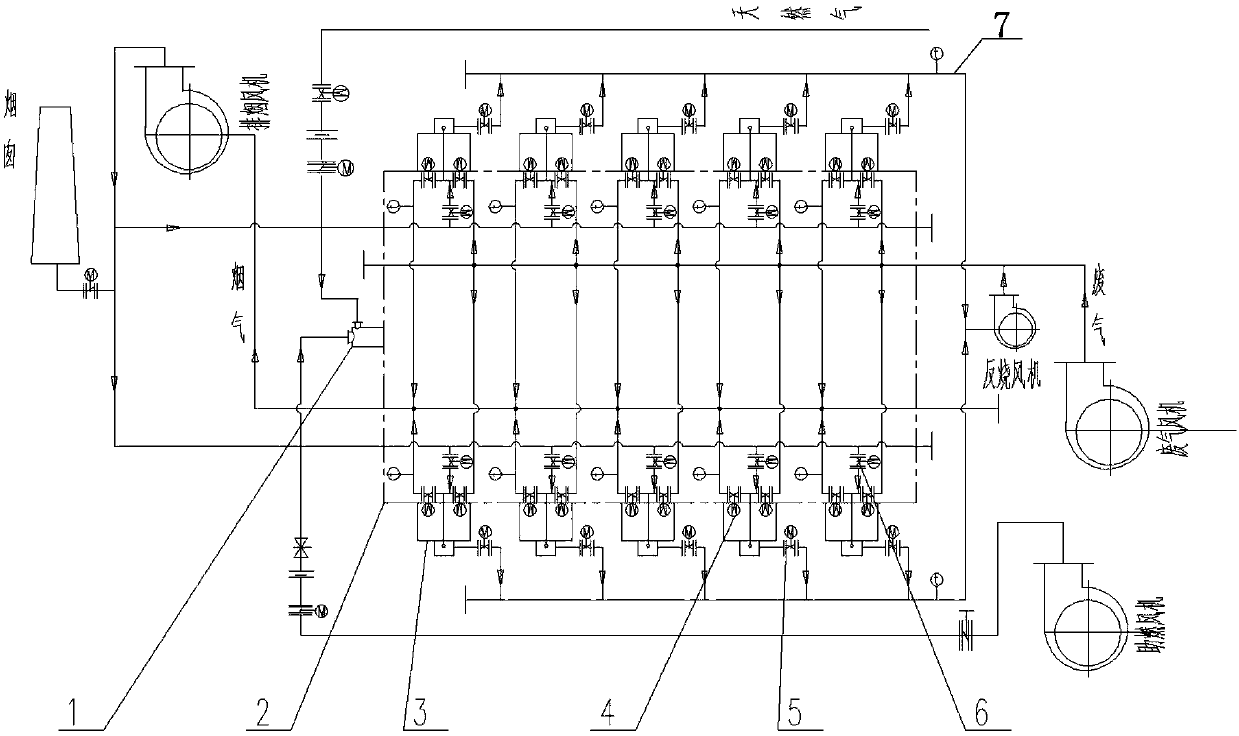

[0030] like figure 1 As shown, the carbon roaster flue gas pollutant regenerative incinerator includes a combustion chamber 2 , a regenerator 3 , a reversing system 4 , a backburning system 5 and a purge system 6 . The combustion chamber 2 is located in the middle of the incinerator, and two groups of regenerators 3 are symmetrically arranged on both sides of the combustion chamber 2, and each group of regenerators 3 includes 5 regenerators. The regenerator 3 communicates directly with the combustion chamber 2, the purge system 6 communicates with the combustion chamber 2 via the regenerator 3, and the left and right groups of regenerators 3 respectively communicate with the exhaust pipe and the chimney via the reversing system 4, and the regenerator 3 It communicates with the anti-burn fan through the anti-burn system 5 and the exhaust duct 7. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com