Spiral type oil separator

An oil separator and spiral technology, which is used in refrigeration components, refrigerators, lighting and heating equipment, etc., to achieve the effect of improving flow splitting efficiency, reasonable structure and reducing airflow velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

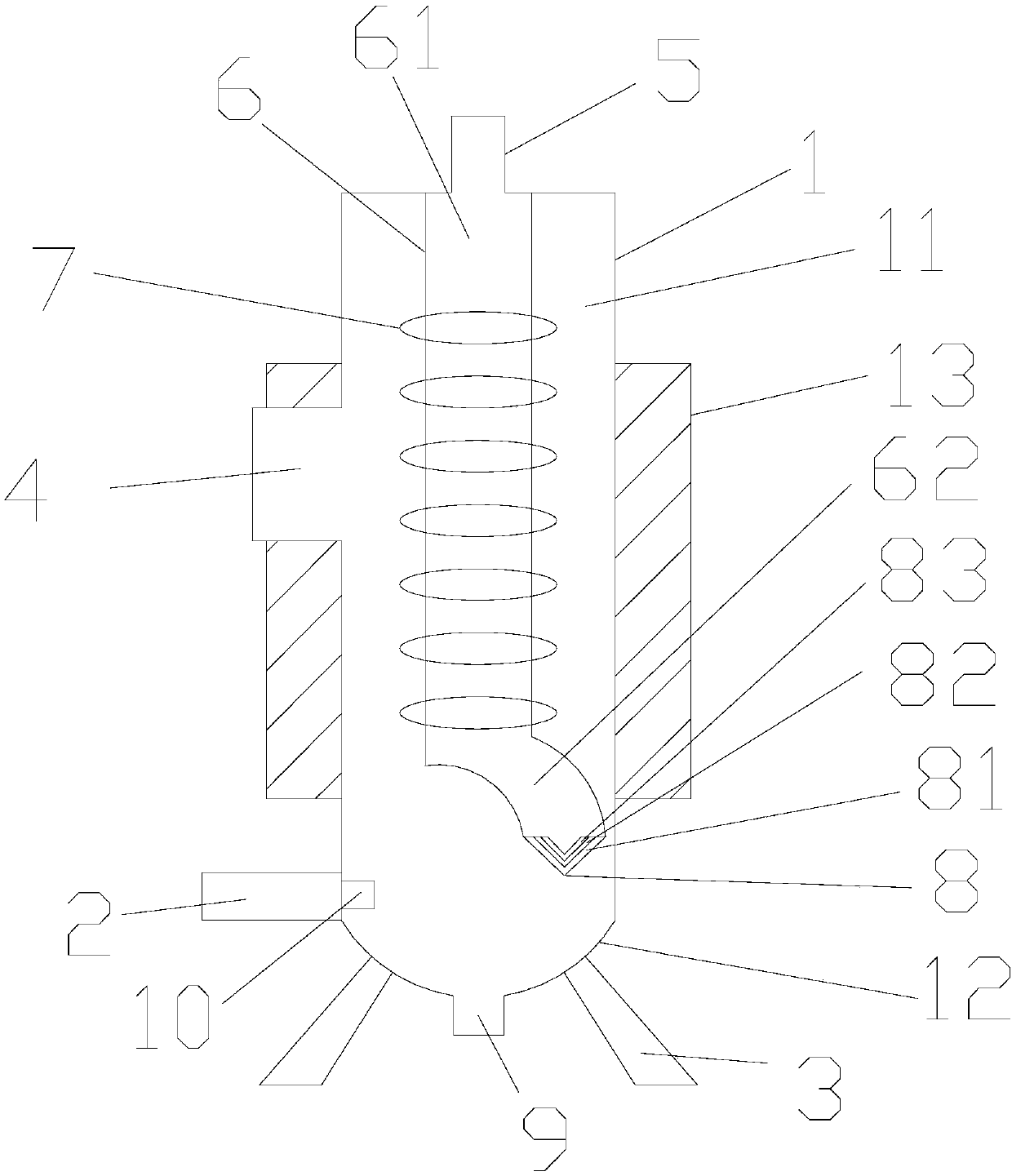

[0014] refer to figure 1 , the present invention provides a spiral oil separator, including a separation cylinder 1, an oil return pipe 2, a bracket 3, an air inlet pipe 4, an air outlet pipe 5, a separation cylinder 6, a spiral guide vane 7, a baffle plate 8, and a waste liquid outlet pipe 9. The separation cylinder 1 includes a cylindrical cylinder 11 and a bottom cover 12, the several brackets 3 are connected to the bottom cover 12 of the separation cylinder 1, and the brackets 3 and the bottom cover 12 are fixed together by welding. The inlet pipe 4 is installed on the side wall of the cylinder 11 of the separation cylinder 1, the outlet pipe 5 is installed on the top of the cylinder 11 of the separation cylinder 1, and the separation cylinder 6 is installed on the cylinder 11 of the separation cylinder 1 The inside of the separation cylinder 6 is connected to the top of the cylindrical cylinder 11, the outer wall of the separation cylinder 6 is fixed with a spiral guide v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com