Anti-freezing ultralow-temperature refrigerating system and using method thereof

An ultra-low temperature refrigeration and anti-freezing technology, which is applied in the direction of refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of hidden safety hazards in the box, current leakage of heating wires, cracking, brittle and hard aging, etc., to achieve effective heat exchange avoidance, Structure optimization, avoiding the effect of precipitation and solidification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

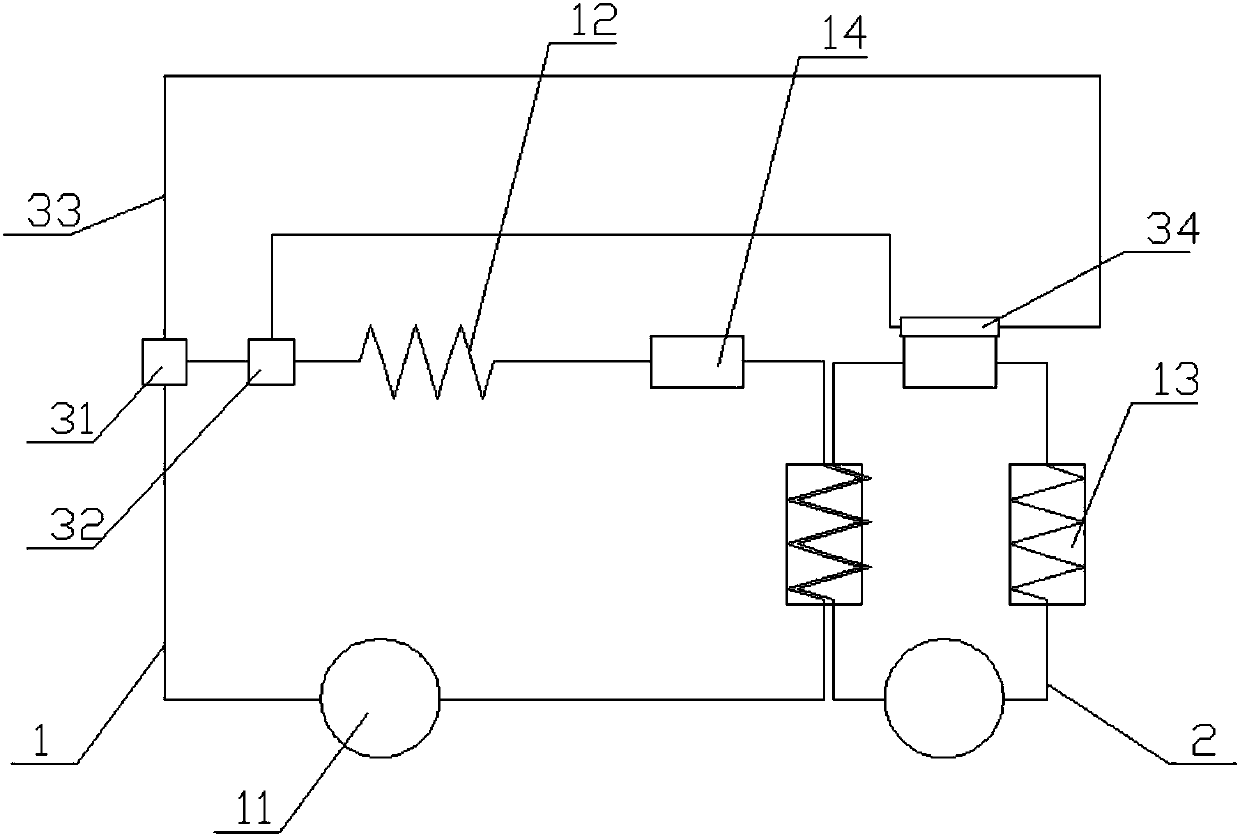

[0033] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of Embodiment 1 of the anti-freezing ultra-low temperature refrigeration system of the present invention. The refrigeration system includes a first refrigeration assembly 1 and a second refrigeration assembly 2. Both the first refrigeration assembly 1 and the second refrigeration assembly 2 include compression machine 11, condenser 12, evaporator 13, and capillary tube 14, the first refrigeration assembly 1 and the second refrigeration assembly 2 respectively connect the compressor 11, the condenser 12, and the evaporation The device 13 is connected with the capillary 14 to form an independent refrigeration cycle.

[0034] The evaporator 13 of the first refrigeration assembly 1 and the condenser 12 of the second refrigeration assembly 2 are arranged correspondingly, so as to ensure that the evaporator 13 of the first refrigeration assembly 1 can cool the second refrigeration assembly 1 The conden...

Embodiment 2

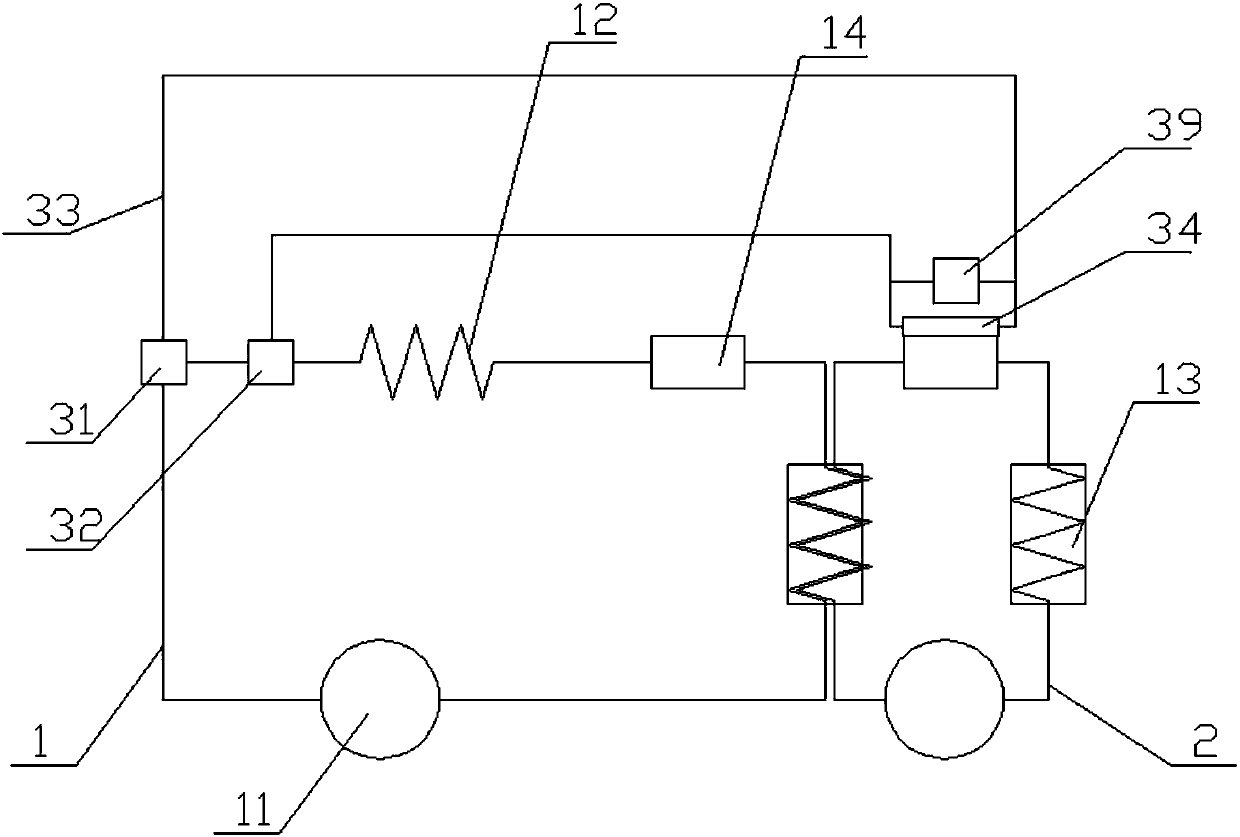

[0040] Such as figure 2 as shown, figure 2 It is a structural schematic diagram of Embodiment 2 of the anti-freezing ultra-low temperature refrigeration system of the present invention. Embodiment 2 is further improved on the basis of Embodiment 1. The improvement is that the heat exchange section 34 and the circulation pipes 33 at both ends Connected at a certain angle, the heat exchange section 34 is provided with a blocking assembly.

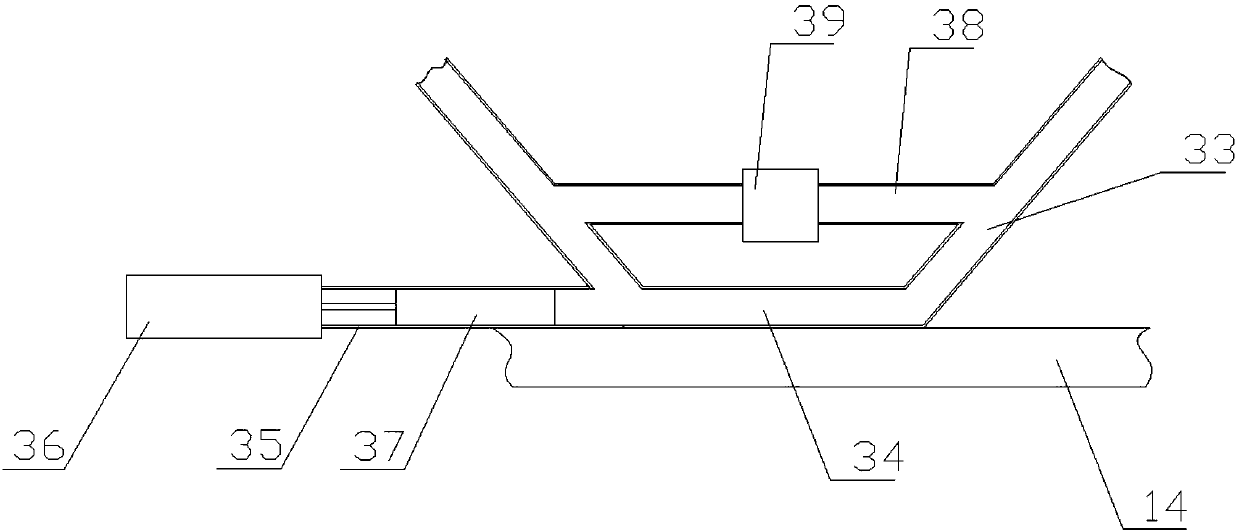

[0041] Such as image 3 as shown, image 3 It is a partial structural schematic diagram of the second embodiment of the heating assembly; the blocking assembly includes a transformer tube 35, a brake part 36 and a plug body 37, and the transformer tube 35 and the heat exchange section 34 are arranged coaxially, And the pressure transformation tube 35 is consistent with the inner diameter of the heat exchange section 34; one end of the pressure transformation tube 35 communicates with the heat exchange section 34 and the circulation pipe ...

Embodiment 3

[0046] Such as Figure 4 as shown, Figure 4 It is a partial structural schematic diagram of the third embodiment of the heating assembly; in the third embodiment, the heat exchange section 34 in the second embodiment is set in a spiral shape, and the heat exchange section 34 is spirally wound on the second refrigeration assembly 2 On the outer wall of the capillary 14, it is convenient for the heat exchange of the capillary 14 by the heat exchange section 34. The plug body 37 is set as a flexible material to ensure that when the plug body 37 enters the heat exchange section 34, the plug body 37 can deform and move along the extension track of the heat exchange section 34, realizing the plug body 37 Evacuation of the refrigerant medium in the heat exchange section 34 .

[0047] Since the length of the capillary 14 in the refrigerating cycle of the existing refrigerator is generally set at 0.5 to 3 m, the heat exchange section 34 cannot be in contact with the capillary 14 as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com