Method and device for high-temperature co-gasification of combustible solid waste, biomass and coal

A technology for solid waste and biomass, applied in the production of combustible gas, granular/powder fuel gasification, gasification process, etc., to achieve the effect of reducing processing energy consumption, realizing energy, improving calorific value and energy utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0024] (1) The sorting can adopt the magnetic separator in the prior art to sort combustible solid waste and biomass; The waste and biomass are pulverized; the drying can use the drum dryer in the prior art to dry the pulverized combustible solid waste and biomass, and can use the hot air obtained by heat exchange with flue gas Drying is carried out, and the dried gas can be sent into the combustion process to participate in the combustion, and after participating in the combustion, it becomes a part of the flue gas, which further realizes heat recycling and can effectively reduce pollution.

[0025] (2) The sum of the mass percentages of combustible solid waste and biomass in the mixed material is less than 60%, and the melting temperature of coal in the mixed material is >1150°C.

[0026](3) In order to provide an efficient reaction place for the mixed materials, the reaction temperature of the gasification process is controlled at 800-950°C. Gasification at such a higher te...

Embodiment 1

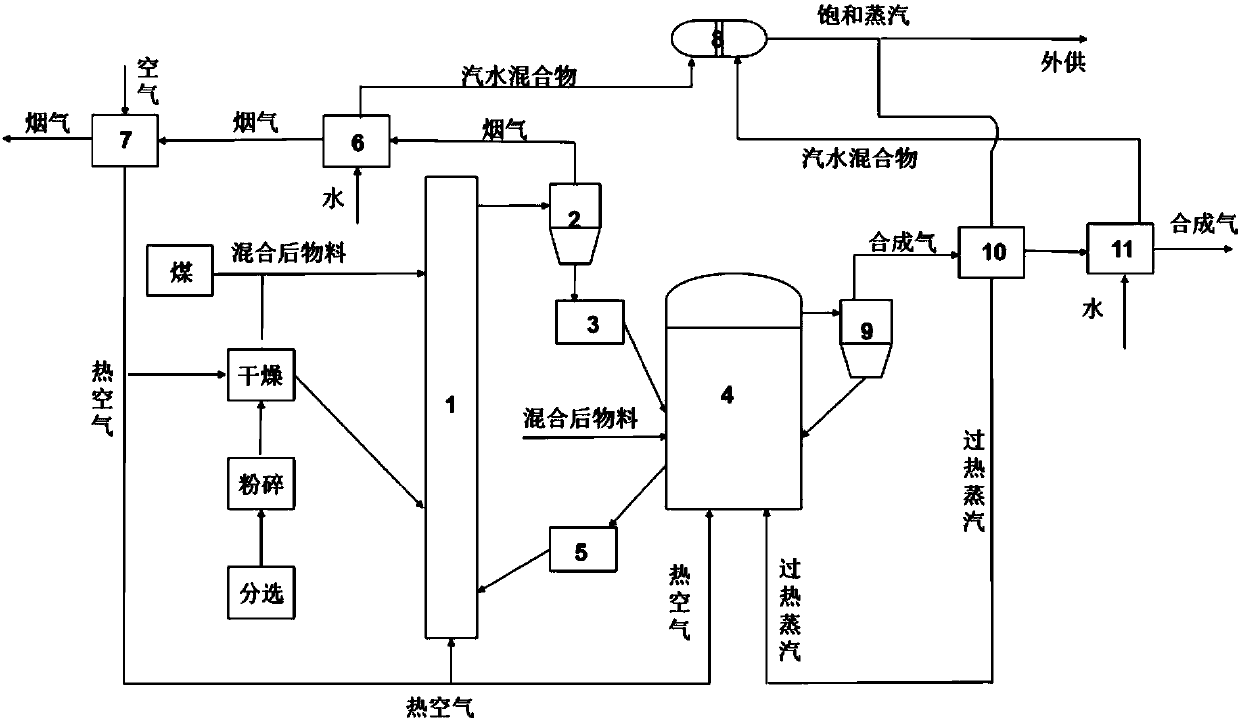

[0040] Such as figure 1 As shown, a combustible solid waste, biomass and coal high-temperature co-gasification device, its specific structure may include: a combustion furnace 1, a first gas-solid separator 2, a first solid return device 3, a bubbling bed gas Furnace 4, second solid feeder 5, first air-water heat exchanger 6, air preheater 7, steam drum 8, second gas-solid separator 9, superheater 10 and second air-water heat exchanger 11. Combustible solid waste and biomass are sequentially sorted, pulverized and dried, and then mixed with coal to obtain a mixed material; the mixed material is sent to the bubbling bed gasifier 4 and the combustion furnace 1 .

[0041] In the bubbling bed gasification furnace 4, the gasification reaction temperature is controlled at 800-950°C, and the synthesis gas with solid particles produced by the bubbling bed gasification furnace 4 is sent to the second gas-solid separator 9 for gas-solid separation. The separated solid particles are re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com