A high-strength peelable film for radioactive decontamination, its preparation method and application

A high-strength, radioactive technology, applied in the field of chemical and chemical decontamination, to achieve high efficiency, easy to peel off large pieces, and remarkable decontamination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

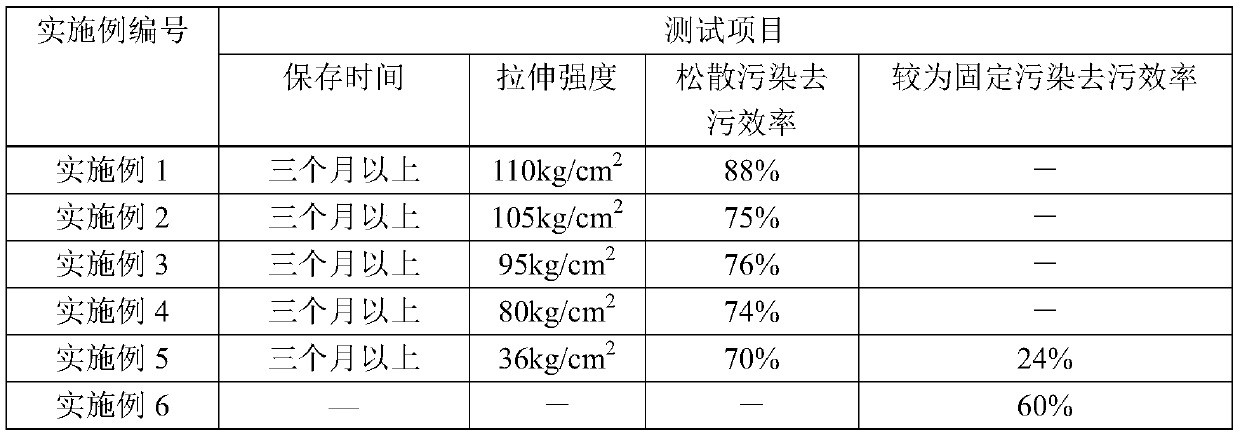

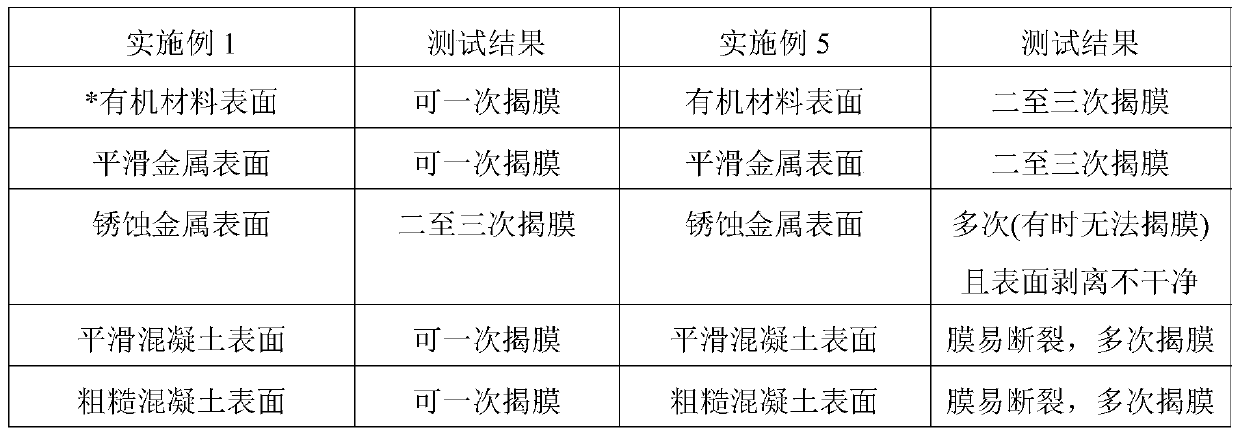

Examples

Embodiment 1

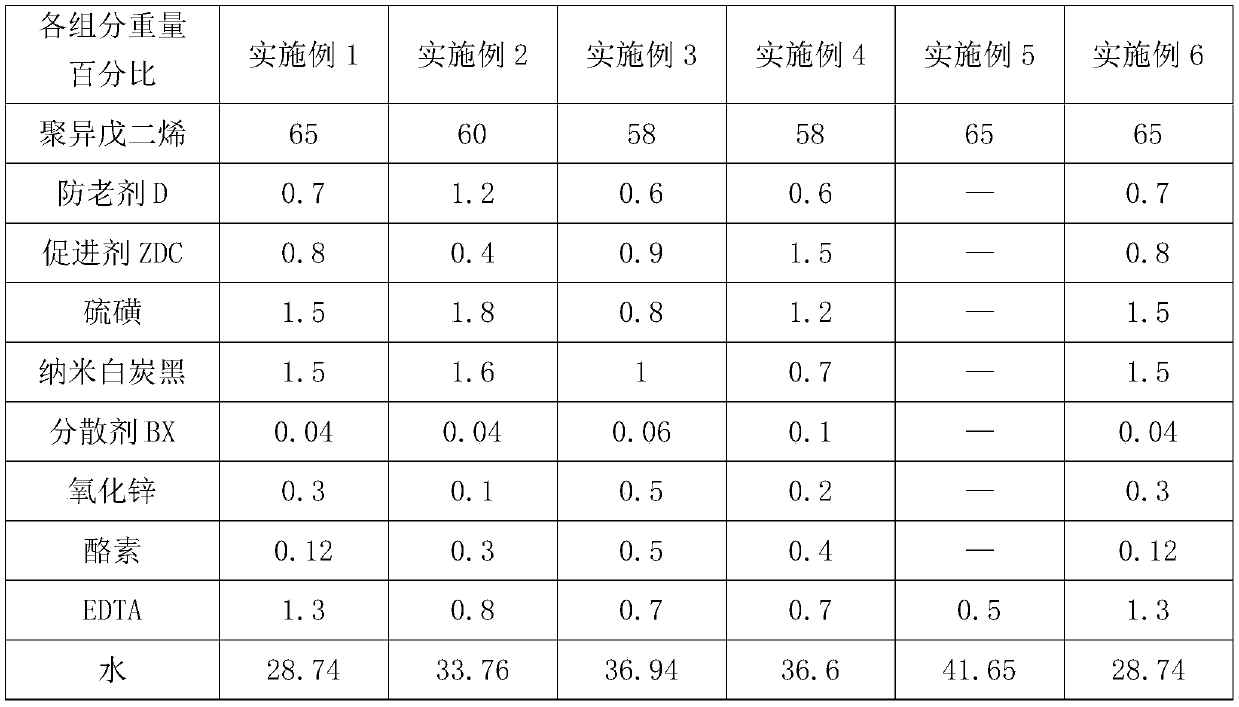

[0039] Embodiment 1. The modified polyisoprene film-forming base material is adopted, and the formula is shown in Table 1. Wherein, when synthesizing the detergent, EDTA solution and glycerol are added in sequence under stirring at normal temperature and pressure, stirred for 10-30 minutes, left to stand for 2-4 hours before use.

[0040] Using the method of spraying, the decontamination experiment was carried out on the actually contaminated radioactive contamination samples of uranium.

Embodiment 2

[0041] Embodiment 2. Using modified polyisoprene film-forming base material, the formula is shown in Table 1. Its technology is identical with embodiment 1.

Embodiment 3

[0042] Embodiment 3. Using modified polyisoprene film-forming base material, the formula is shown in Table 1. Its technology is identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com