Corrugated paper cutting and stacking integrated equipment

A corrugated paper, integrated technology, applied in the field of corrugated paper cutting and stacking integrated equipment, can solve the problems of difficulty in increasing the speed, reducing equipment purchase costs, low structural fault tolerance, and achieving the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solution claimed in the present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments.

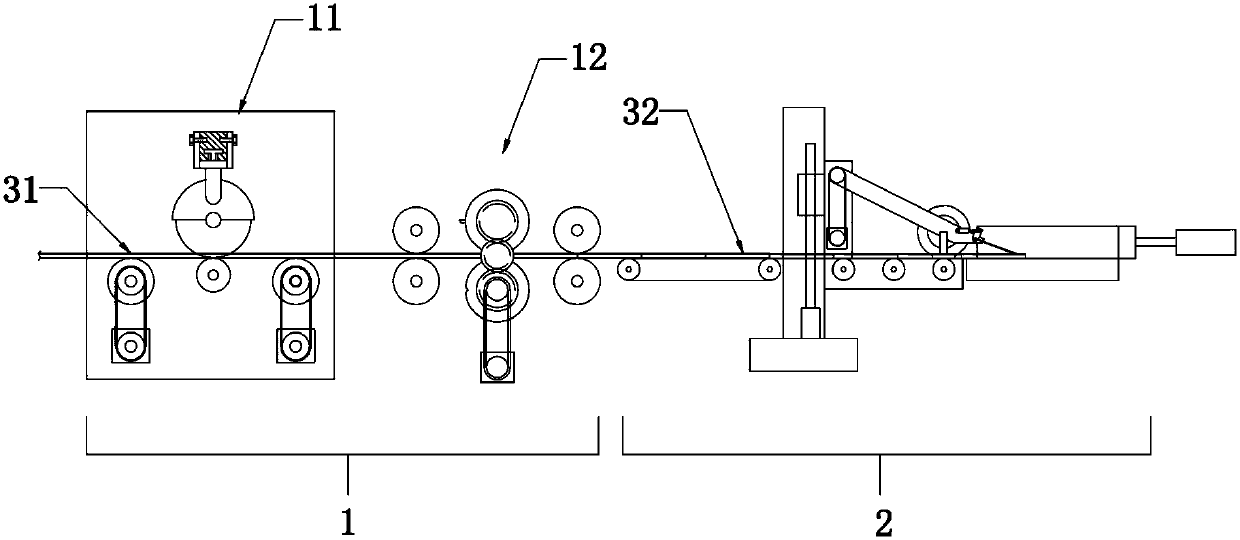

[0026] see figure 1 As shown, the corrugated cardboard cutting and stacking integrated equipment in this embodiment includes a dividing mechanism 1 and a stacking mechanism 2 .

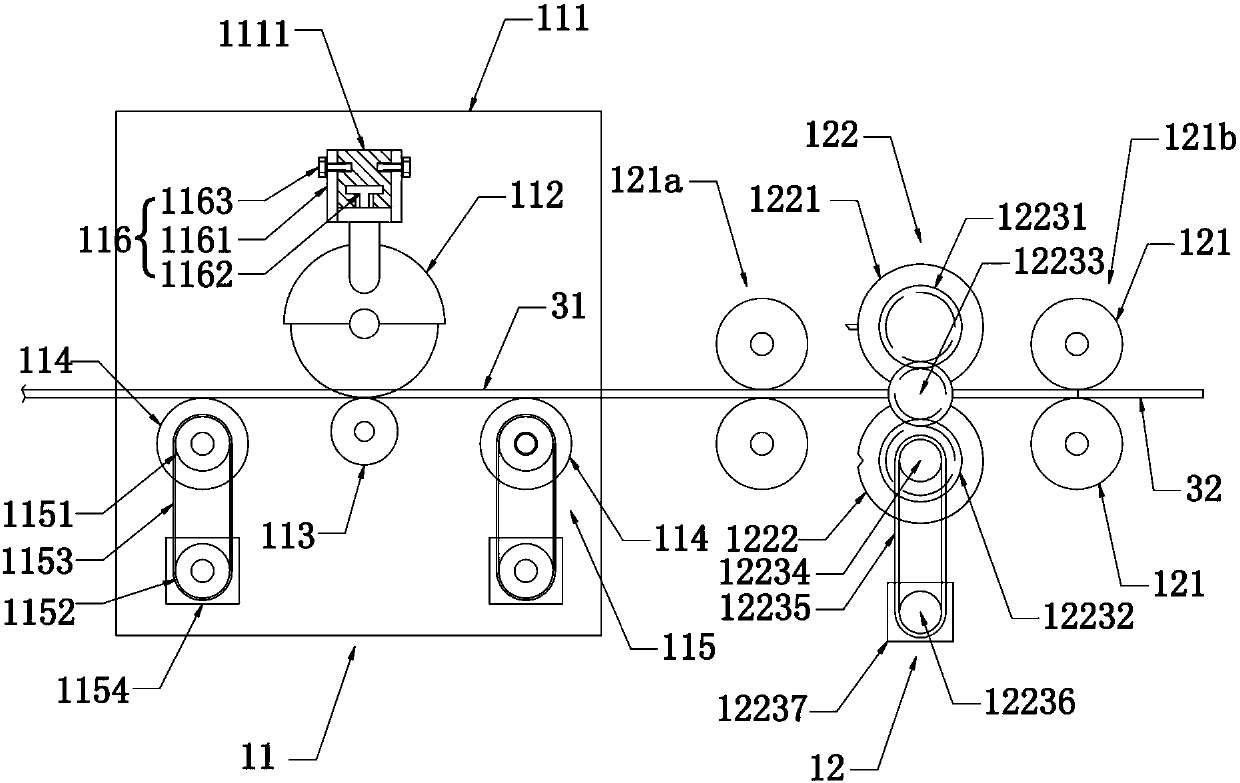

[0027] see Figure 2 to Figure 7 As shown, the dividing mechanism 1 in this embodiment includes a transverse cutting mechanism 11 and a longitudinal cutting structure arranged in sequence according to the conveying direction of the corrugated paper belt 31 .

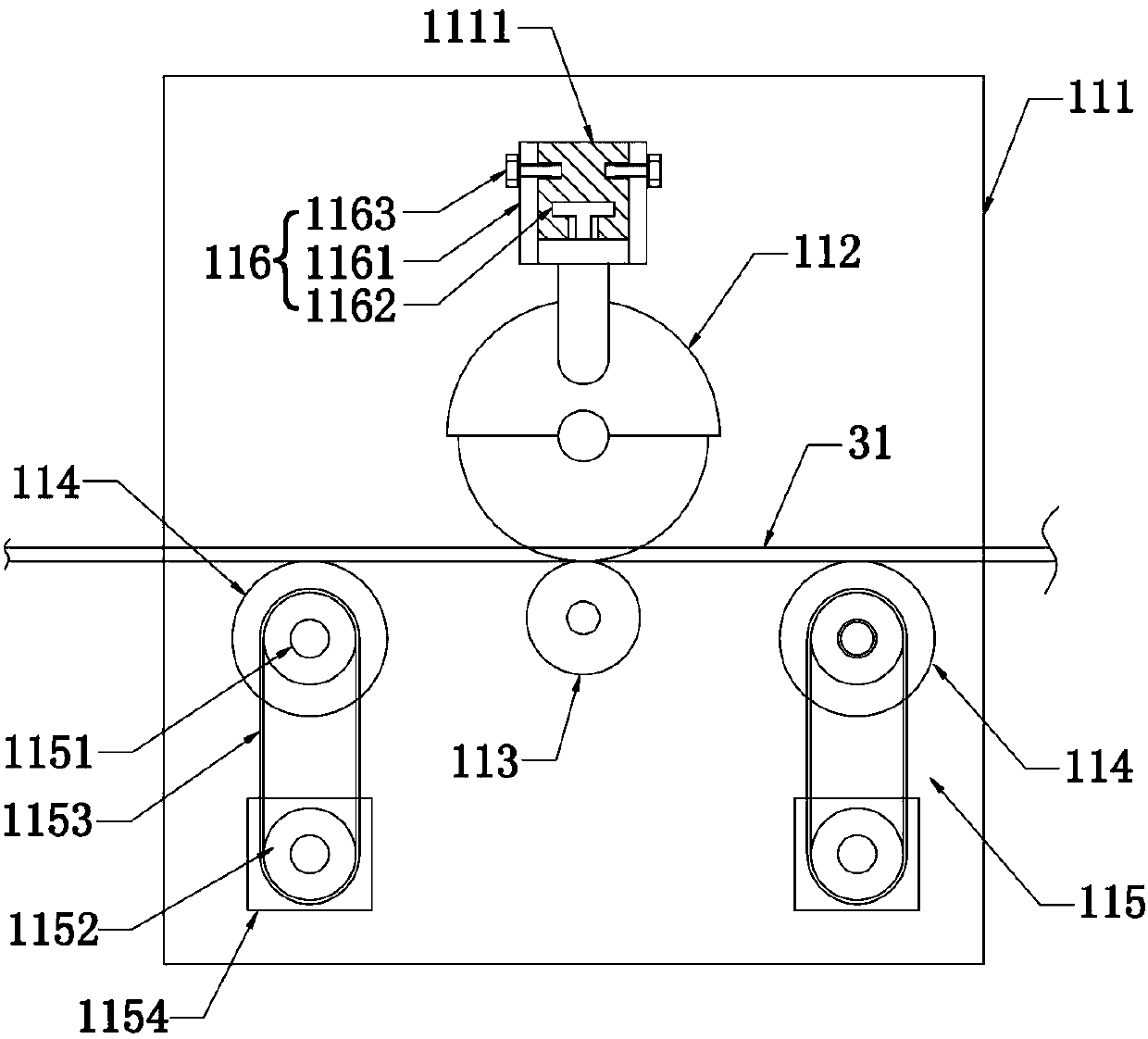

[0028]Wherein, the cross-cutting mechanism 11 includes a cross-cutting mechanism frame 111, an electric wheel saw 112, a carrier roller 113, a conveying roller 114, and a conveying roller driving mechanism 115 for driving the conveying roller 114 to rotate; wherein the cross-cutting mechanism The top of the frame 111 is provided with a transverse guide groove 1111 extending...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com