Ultrafast laser film hole efficient processing method and device

An ultra-fast laser and processing method technology, which is applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of reducing the efficiency of hole making, and the accumulation of residual plasma cannot be discharged, so as to achieve good processing effect and prevent focusing mirror Pollution, good effect of slag discharge efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0028] The invention adopts an ultra-fast laser and a part flip structure to complete the slag discharge effect in the hole making process, and at the same time realizes a process method and a device for efficiently processing the microholes of the part under the action of an auxiliary air flow.

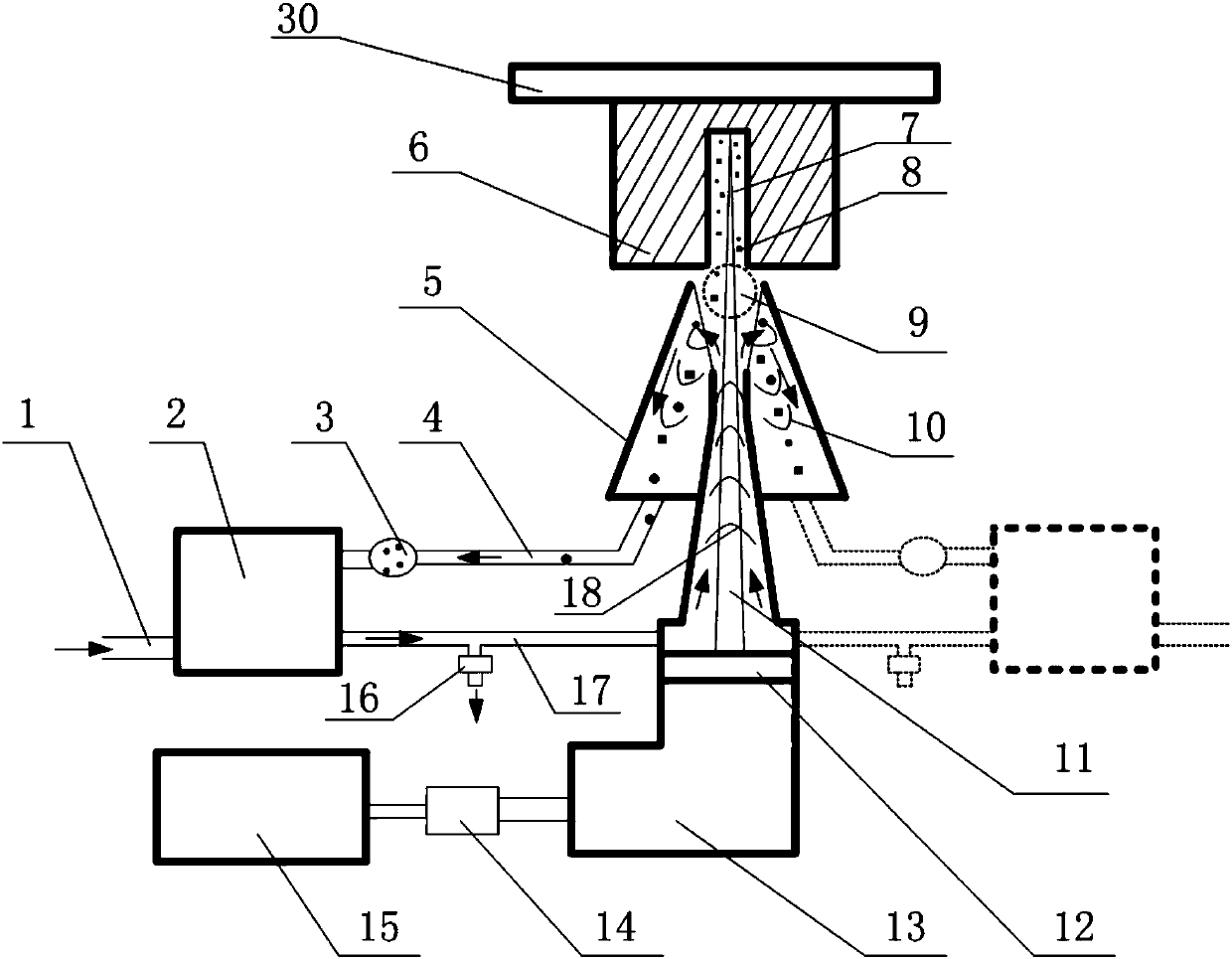

[0029] from figure 1 It can be seen that the device mainly includes a beam scanning drilling system and a slag discharge system. The beam scanning drilling system mainly includes a laser 15 , a beam modulation module 14 , a three-dimensional scanning device 13 , a focusing mirror 12 and a workbench 30 arranged in sequence. The pre-processed part 6 is fixed upside down on the table 30 . The laser beam is emitted from the laser 15, and after being modulated and shaped by the beam modulation module 14, it is deflected and translated by the three-dimens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com