Atmosphere control method of forming cavity of slm equipment

A control method and technology for forming a cavity, which are applied in the directions of additive manufacturing, process efficiency improvement, and additive processing, etc., can solve the problems of a large amount of gas consumption, high requirements for airtightness of the cavity, damage to the vacuum pump, etc., and the atmosphere is easy to maintain. , Good control stability, good effect of cleaning the cavity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

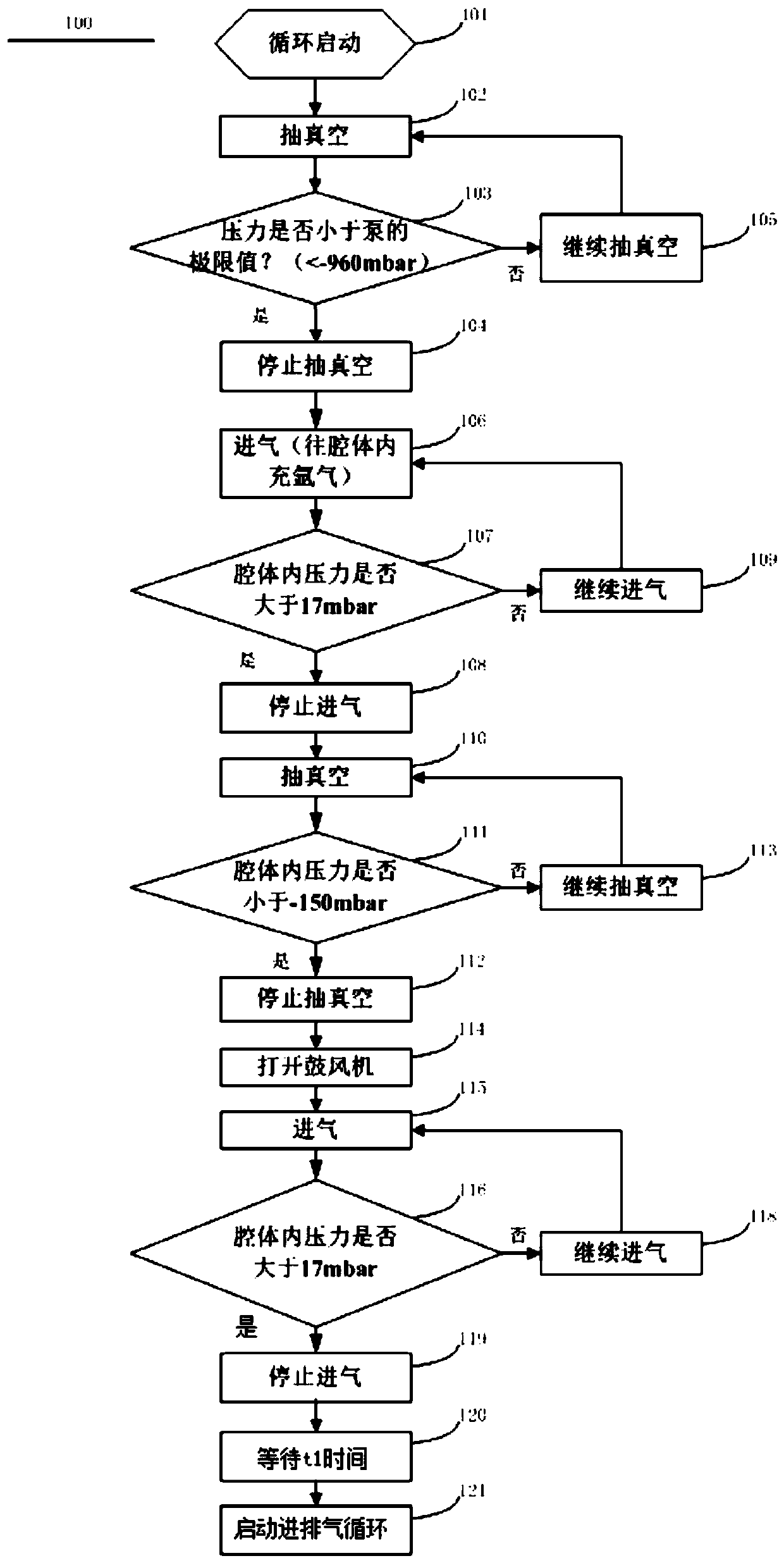

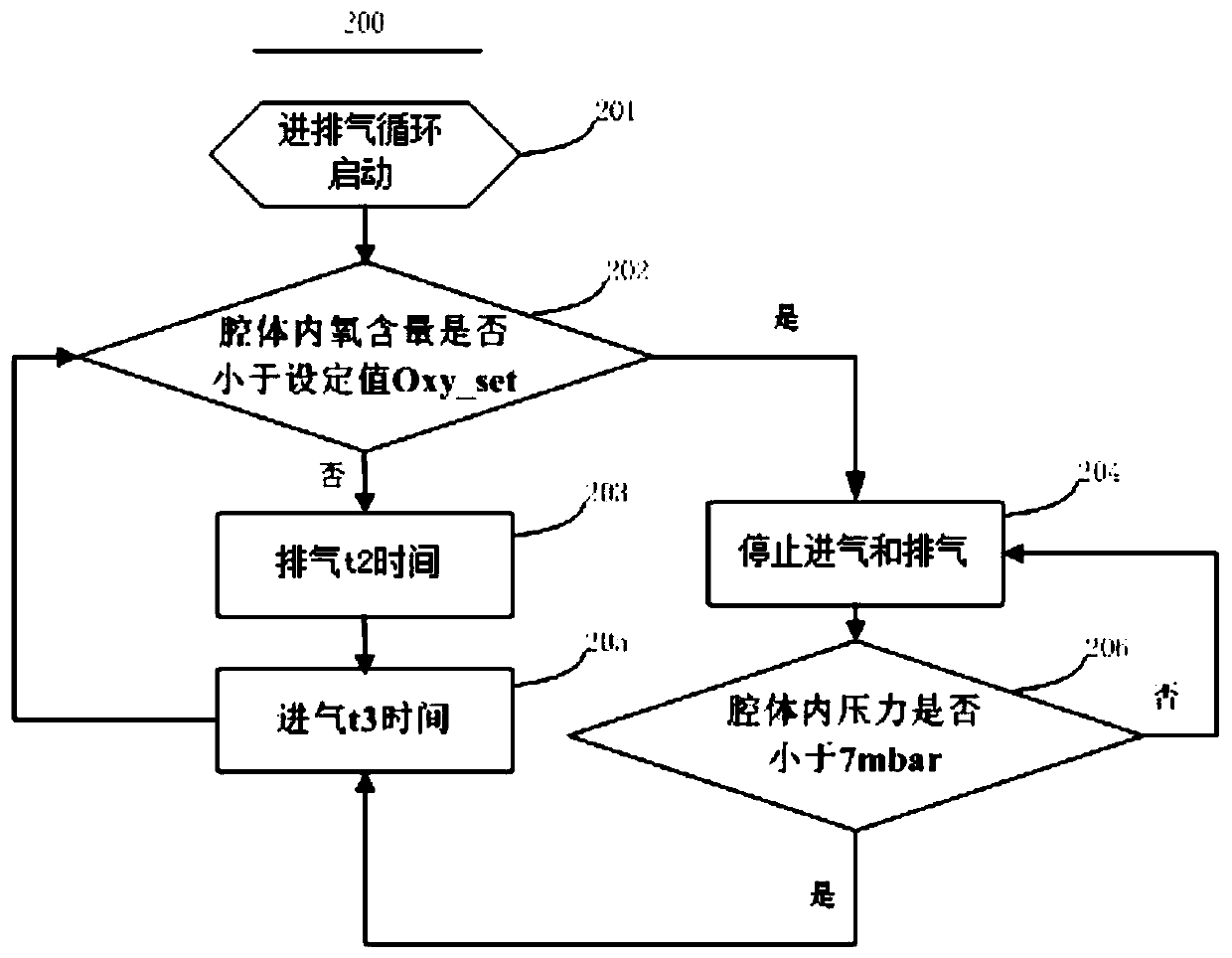

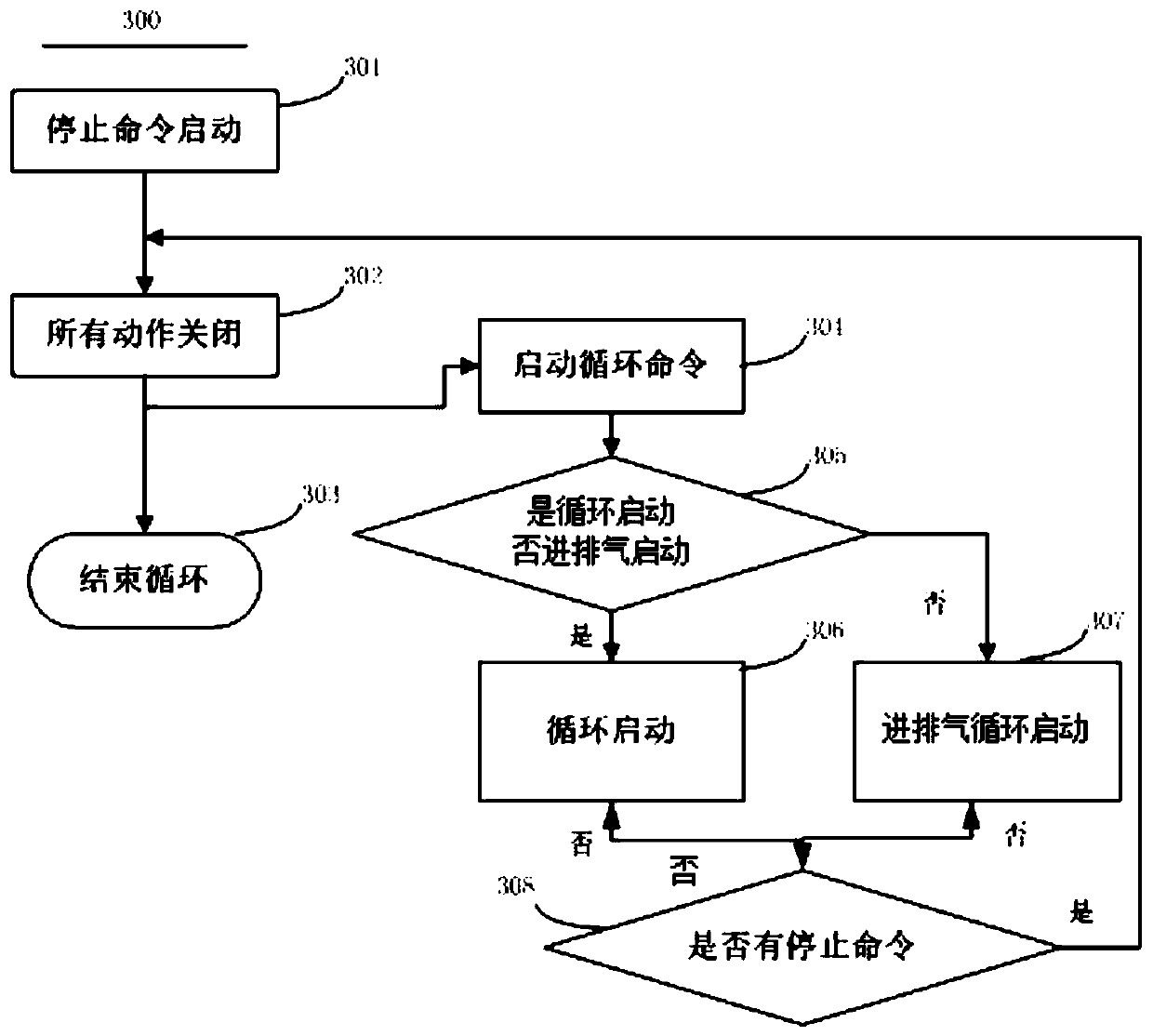

[0023] Below, combined with Figure 1~3 , an embodiment of the method for controlling the atmosphere of the forming cavity of the SLM equipment according to the present invention will be described in detail. This embodiment is only an example to illustrate a preferred embodiment of the present invention, but does not constitute a limitation to the present invention.

[0024] figure 1 It is a schematic flow chart of the cycle starting step 100 of the method for controlling the atmosphere of the forming cavity of the SLM equipment in this embodiment; figure 2 is a schematic flow chart of the start step 200 of the intake and exhaust cycle in this embodiment; image 3 is a schematic flowchart of the stop loop step 300 of this embodiment.

[0025] As shown in the drawings, the method for controlling the atmosphere of the forming cavity of the SLM equipment in this embodiment includes a cycle start step 100 , an intake and exhaust cycle start step 200 , and a cycle stop step 300...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com