Novel U-shaped screw bender

A bending machine and U-shaped technology, which is applied in the field of new U-shaped screw bending machines, can solve the problems that the personal safety of operators cannot be guaranteed, the working intensity of operators is reduced, and the bending requirements cannot be met, so as to improve the overall stability , Enhanced practicability, conducive to the effect of popularization and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

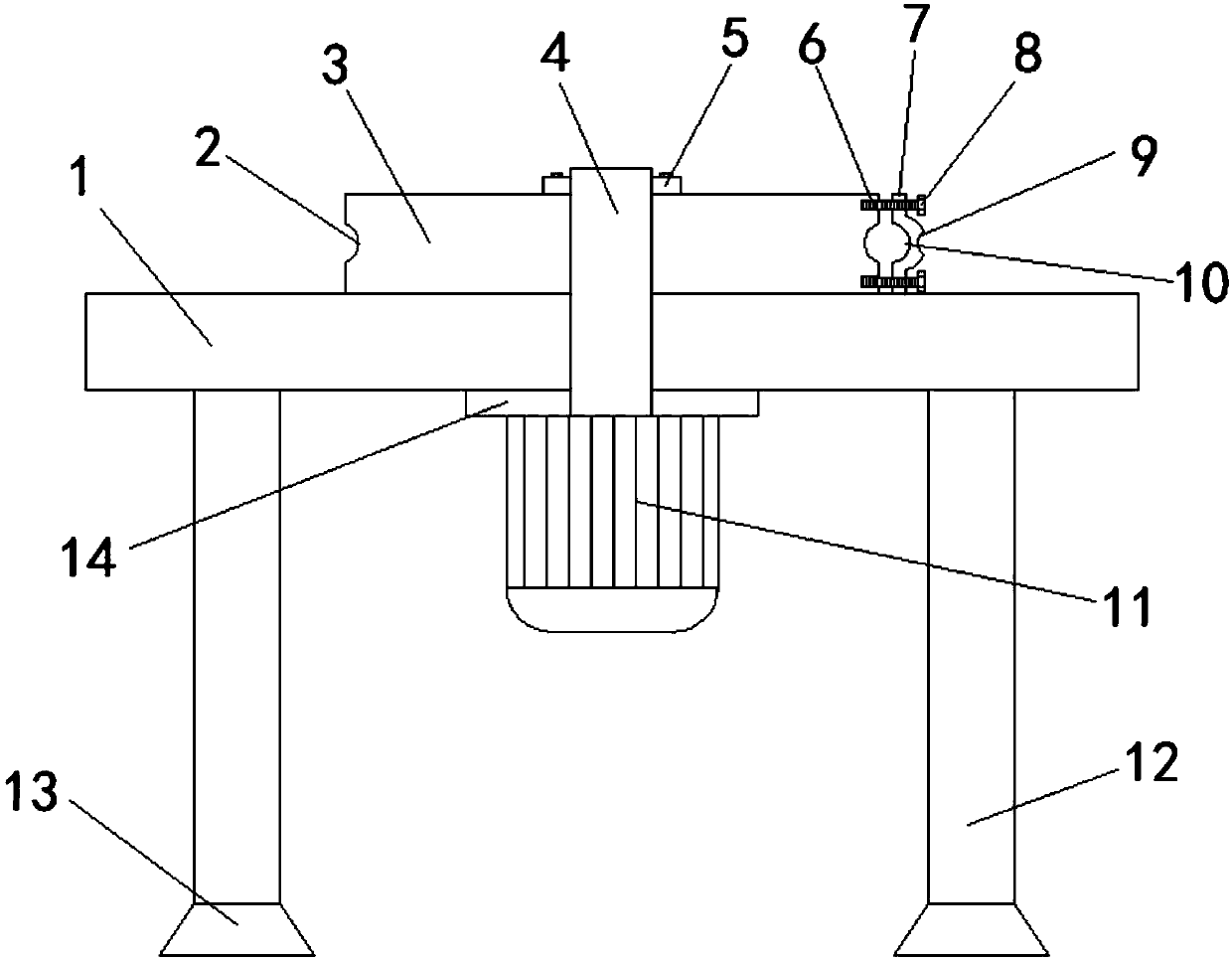

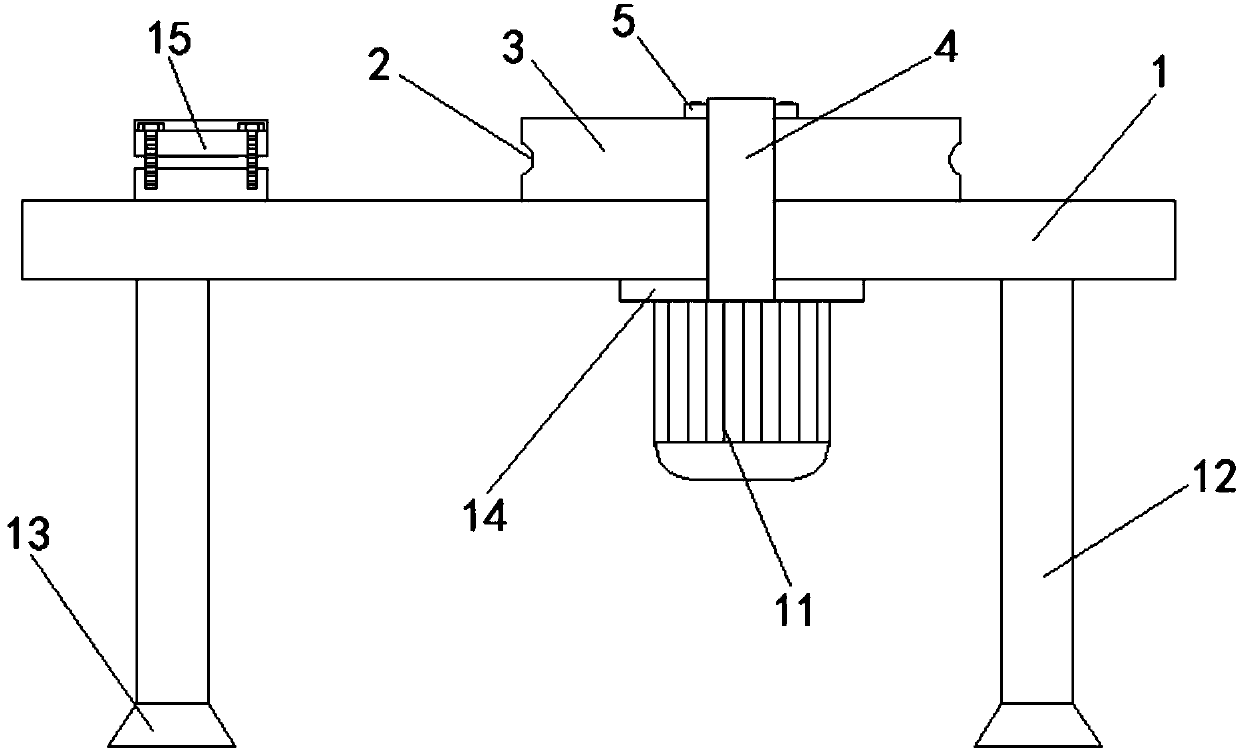

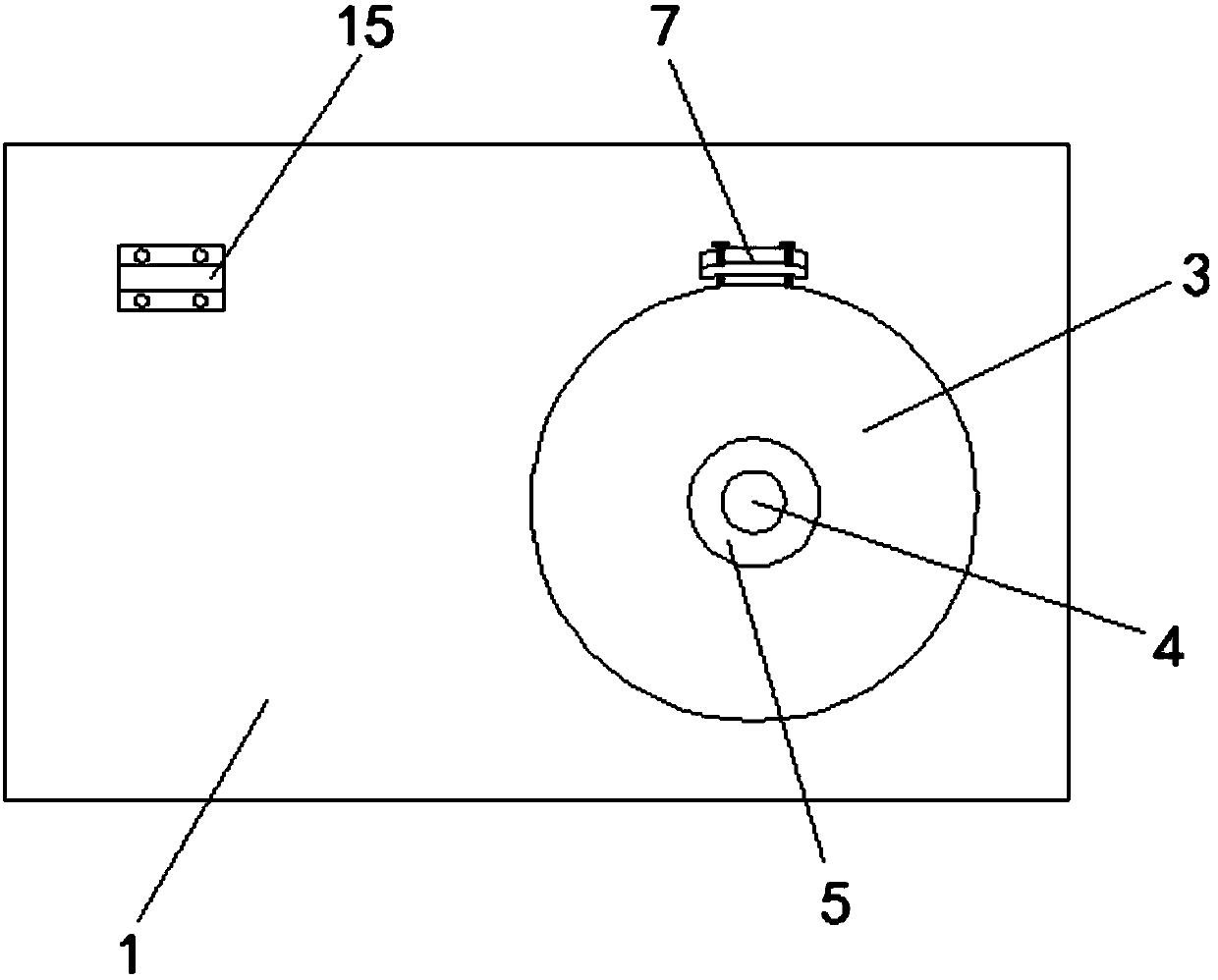

[0021] In order to further understand the content, features, and effects of the present invention, the following embodiments are listed in conjunction with the accompanying drawings.

[0022] Combine below Figure 1-4 The new U-shaped screw bending machine of the present invention is described in detail: a new type of U-shaped screw bending machine, including an operating platform 1, a bending disc mold 3, a rotating shaft 4, a positioning buckle 7, a motor 11, and a support leg 12 And a limit device 15, the operating platform 1 is provided with supporting legs 12 at four corners, the bottom ends of the supporting legs 12 are fixedly connected with feet 13, and the central position of the operating platform 1 is provided with a motor 11, the motor 11 is fixedly connected to the lower surface of the operating platform 1 through the first flange 14, the output end of the motor 11 is connected with a rotating shaft 4, the rotating shaft 4 sequentially penetrates the first flange 14 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com