Frame type driving rotor dust treatment device for feed stirring motor

A feed mixing and dust treatment technology, applied in mixer accessories, feed, application and other directions, can solve the problems of unclean treatment, poor treatment effect, poor dust removal effect, etc., to avoid secondary adhesion, simple structure, Practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

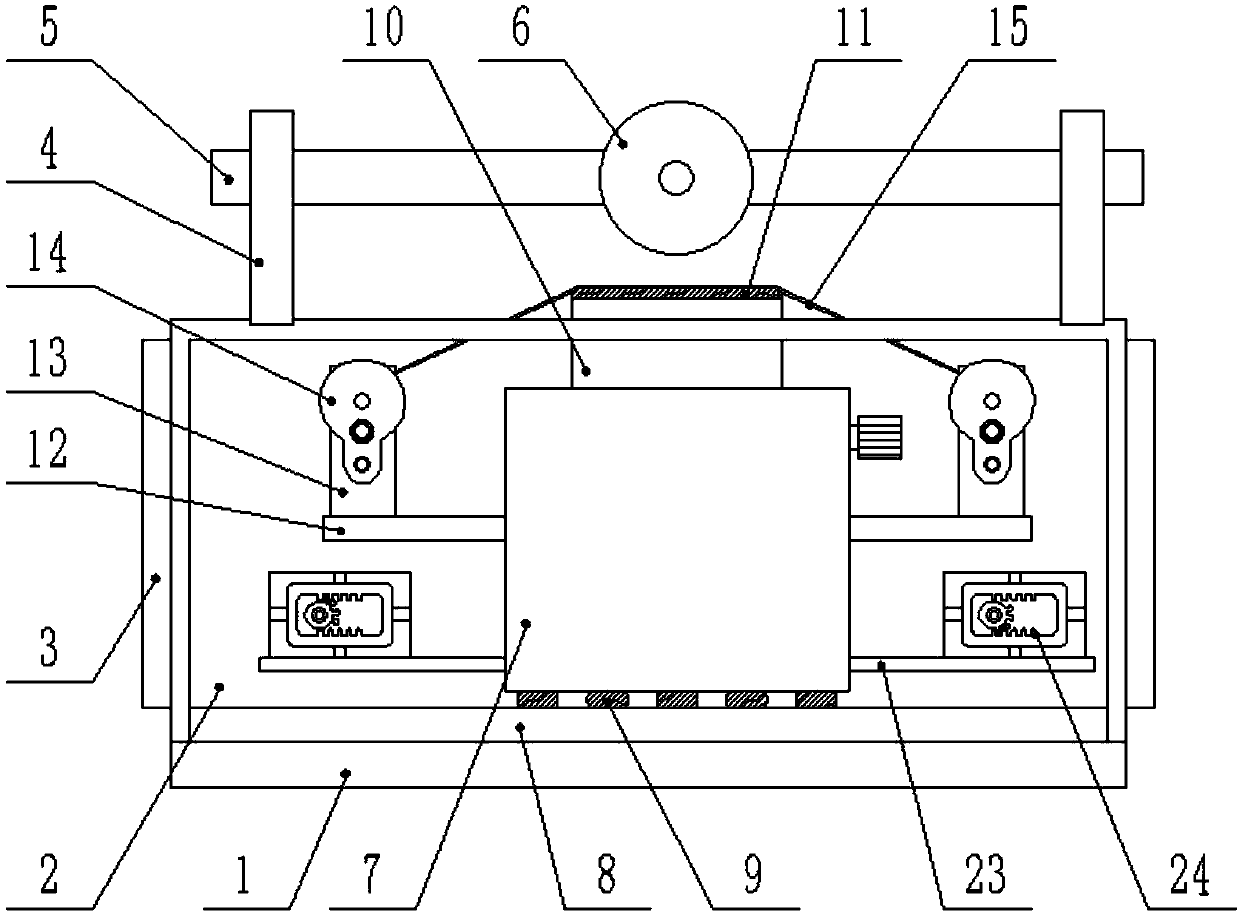

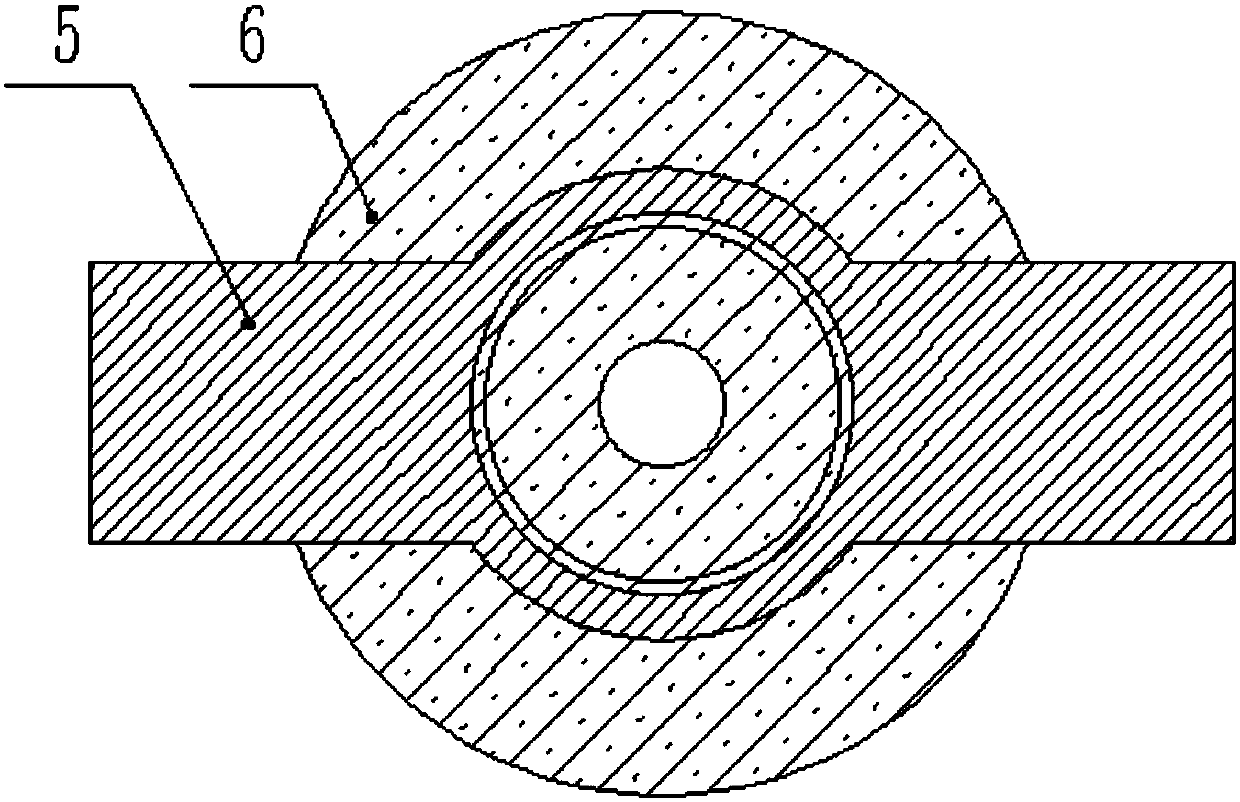

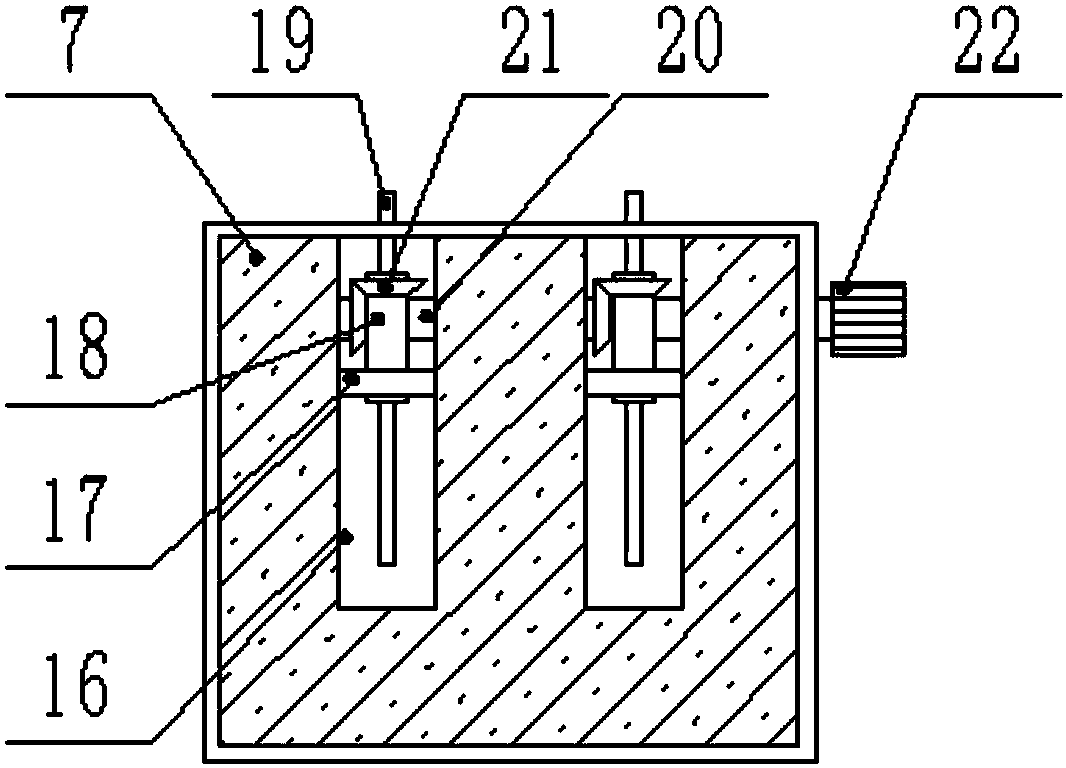

[0020] see Figure 1-3 , a frame-driven rotor dust treatment device for a feed mixing motor, comprising a device body, a base 1 is provided on the device body, a power cabin 2 is arranged above the base 1, and a passage between the power cabin 2 and the base 1 The way of welding is fixedly connected, the maintenance door 3 is set on both sides of the power cabin 2, and the interior of the power cabin 2 is communicated through the maintenance door 3, and the top of the power cabin 2 is provided with a support rod 4, and the support rod 4 is connected to the power supply. The cabins 2 are fixedly connected by welding, the support bar 4 is provided with a crossbeam 5, and the crossbeam 5 is welded to the support bar 4, and the middle position of the crossbeam 5 is provided with a rotor connector 6. The rotor connecting piece 6 and the crossbeam 5 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com