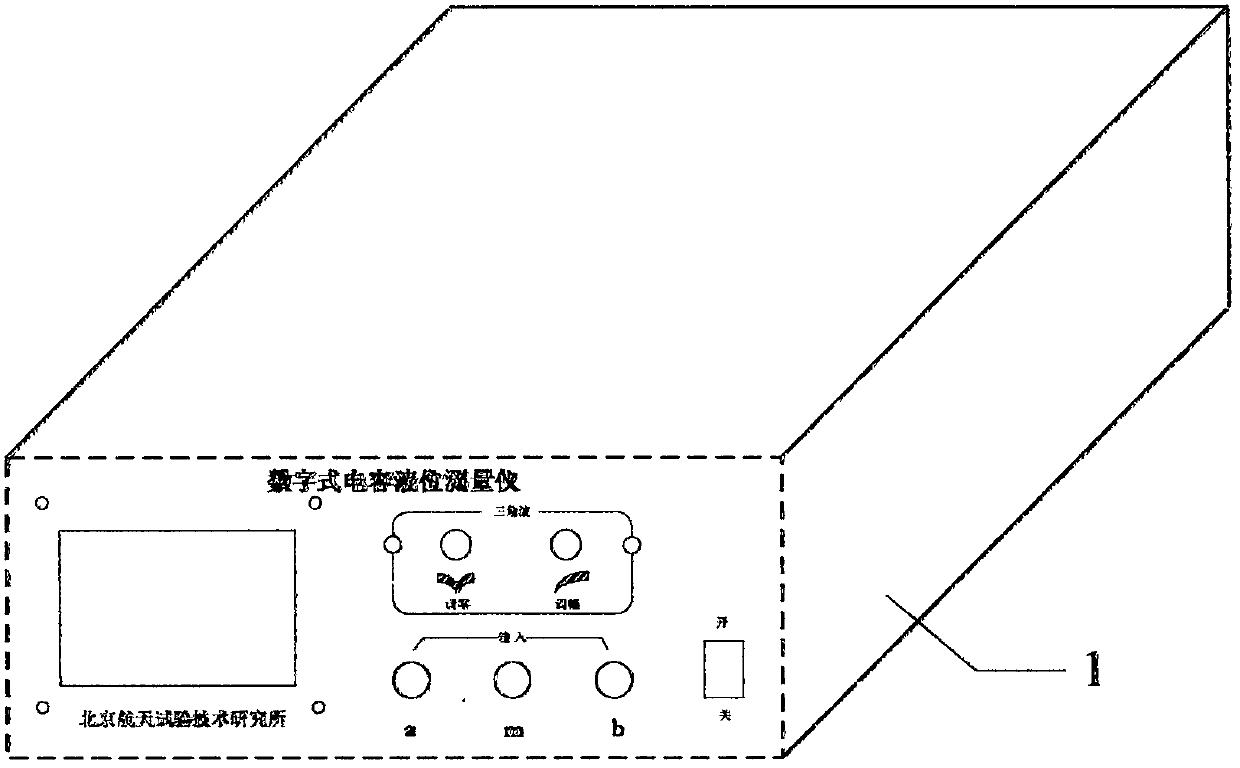

Digital capacitive liquid level measuring system

A technology of capacitive liquid level and measurement system, applied in liquid/fluid solid measurement, measurement device, liquid level indicator for physical variable measurement, etc., can solve the problems of low stability, low precision, and distortion of output signal, etc. Achieve the effect of strong real-time tracking ability, high working stability and high conversion sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

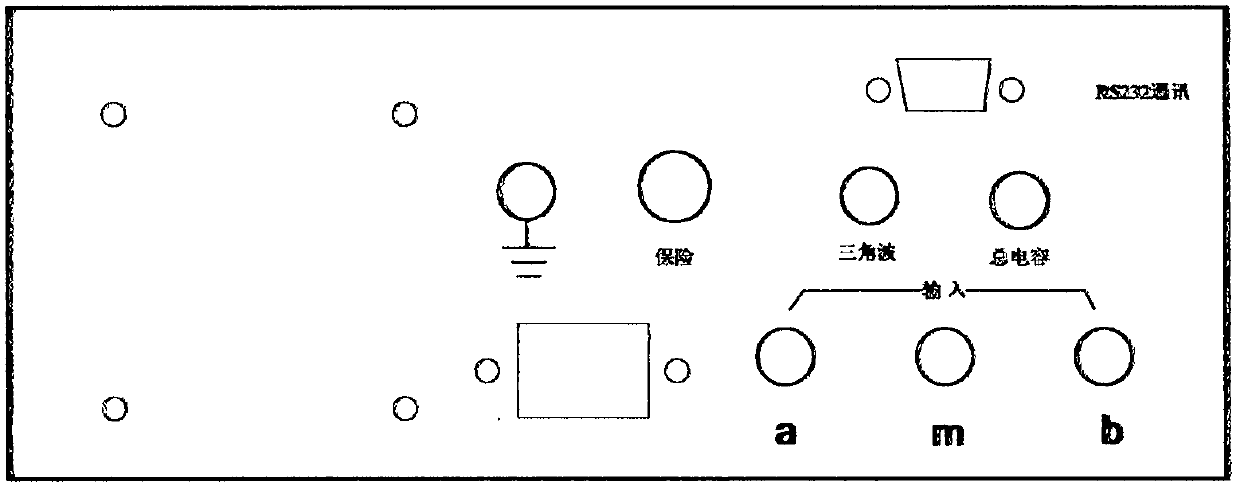

[0014] The internal circuit of the instrument is divided into three parts: analog circuit, digital circuit and power circuit, which are respectively implemented on three circuit boards. Among them, the C-V conversion circuit is the analog part. In the process of designing the circuit, a lot of simulation work has been done with Multisim software. Finally, determine the best parameters of the resistance-capacitance components in the circuit, thereby replacing the adjustable potentiometer with a fixed resistance resistance; the core of the digital part is the FPGA, which mainly completes the deserialization of high-speed serial data output by the ADC, serial port data transmission and To drive the display function of the liquid crystal display, the FPGA is selected from Altera's cycloneIII series EP3C16E144C8N. The FPGA design is the key to the instrument. The entire development process is completed under the development environment of Altera's Quartus II; powered by.

[0015] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com