Thrust roller pin combination bearing for automobile steering knuckle

An automobile steering knuckle and combined bearing technology, which is applied to rolling contact bearings, rotating bearings, bearings, etc., can solve problems such as affecting the service life of bearings and adverse effects on assembly accuracy, so as to improve bearing life, improve service life, and ensure The effect of installation and use accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

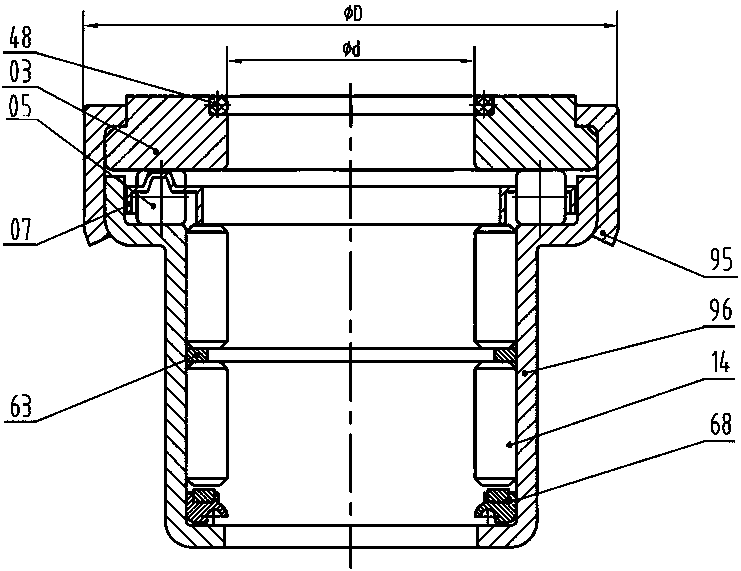

[0018] The present invention will be further explained below in conjunction with accompanying drawing.

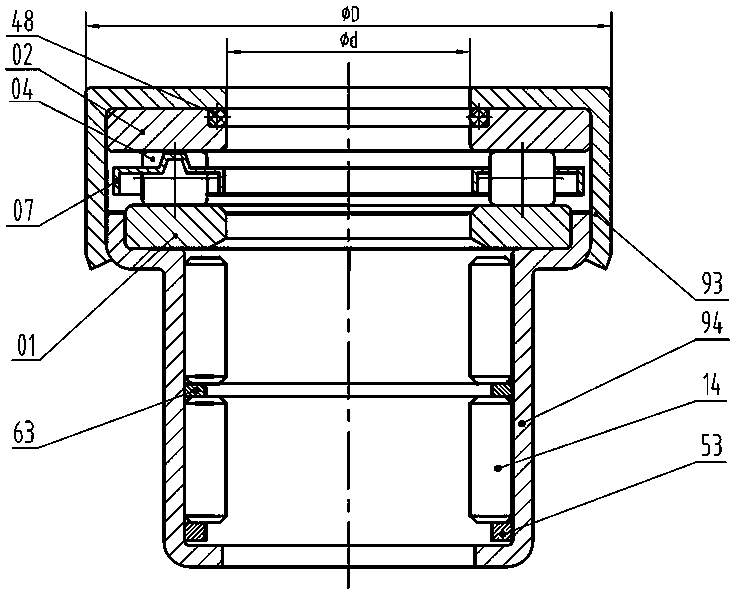

[0019] Such as figure 2 shown. A thrust needle roller combined bearing for an automobile steering knuckle of the present invention includes a shaft ring 03, a rolling element 05, a cage 07, a needle roller 14, a shaft ring O-shaped sealing ring 48, an inner spacer ring 63, a sealing ring assembly 68, and an outer cover 95 and outer ring 96. Wherein, the inner diameter of the shaft ring 03 has a shaft ring O-ring seal 48, the shaft ring O-ring seal 48 is an annular rubber seal ring, and the cage 07 is an engineering plastic cage. There is a step at the chamfer of the large end face of the shaft ring 03, which facilitates the edge of the outer cover 95 to fit on the step, and eliminates the adverse effect of the outer cover 95 on the assembly accuracy. The outer cover 95 has a bottom surface narrower than the large end surface of the shaft ring 03 , the end surface of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com