Column plate inserting-buckling-type mounting structure and method

A technology of installation structure and installation method, which is applied in building construction, covering/lining, construction, etc., can solve the problem of contradiction between the decorative effect of polygonal aluminum plate and the cylindrical surface and installation stability, and achieve reliable installation stability and beautiful decorative effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

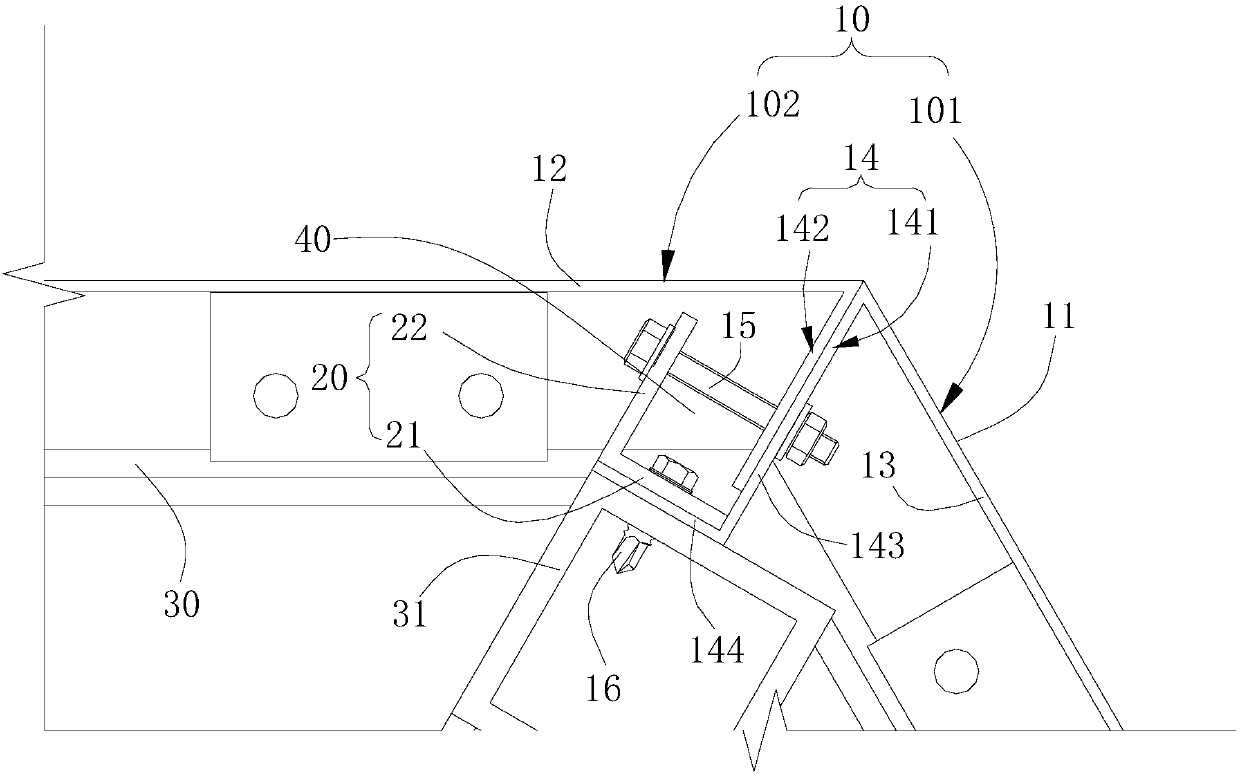

[0030] In order to facilitate the understanding of the present invention, the following will be described in conjunction with the accompanying drawings and embodiments.

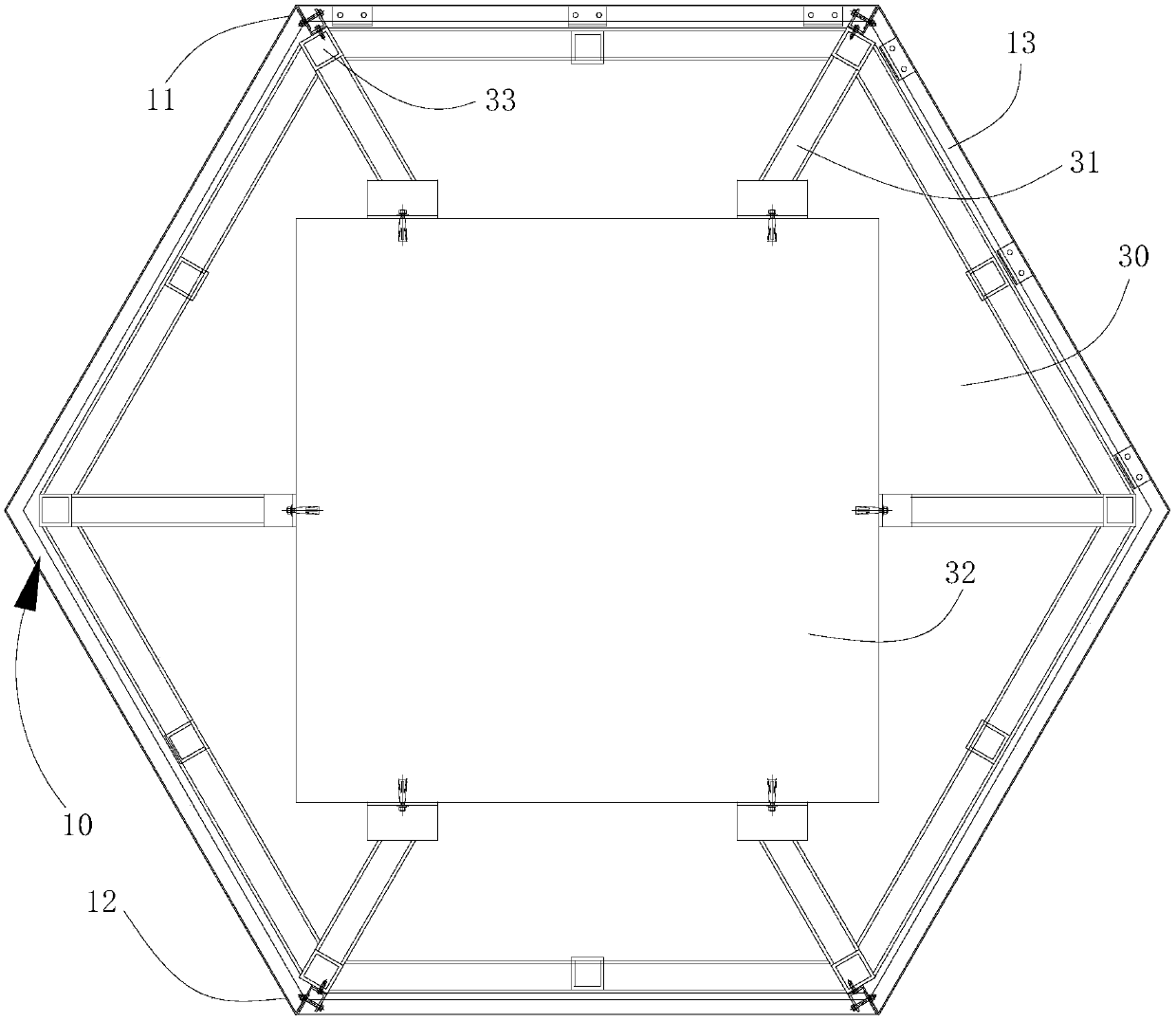

[0031] see Figure 1 to Figure 3 , the present invention provides a column plate plug-in installation structure, which is arranged on the side of the polygonal column plate. The top surface of the polygonal column plate 30 is provided with a keel 31 and a top plate 32. In the middle of the surface, the keels 31 respectively extend from the corners 33 of the top surface of the polygonal column plate 30 to the center of the top surface of the polygonal column plate 30 , and the installation structure includes a plurality of flanged plates 10 .

[0032] In a preferred embodiment of the present invention, the polygonal column plate 30 can be a regular hexagonal aluminum plate column, but it is not limited thereto, and can be adjusted according to actual construction conditions.

[0033] in:

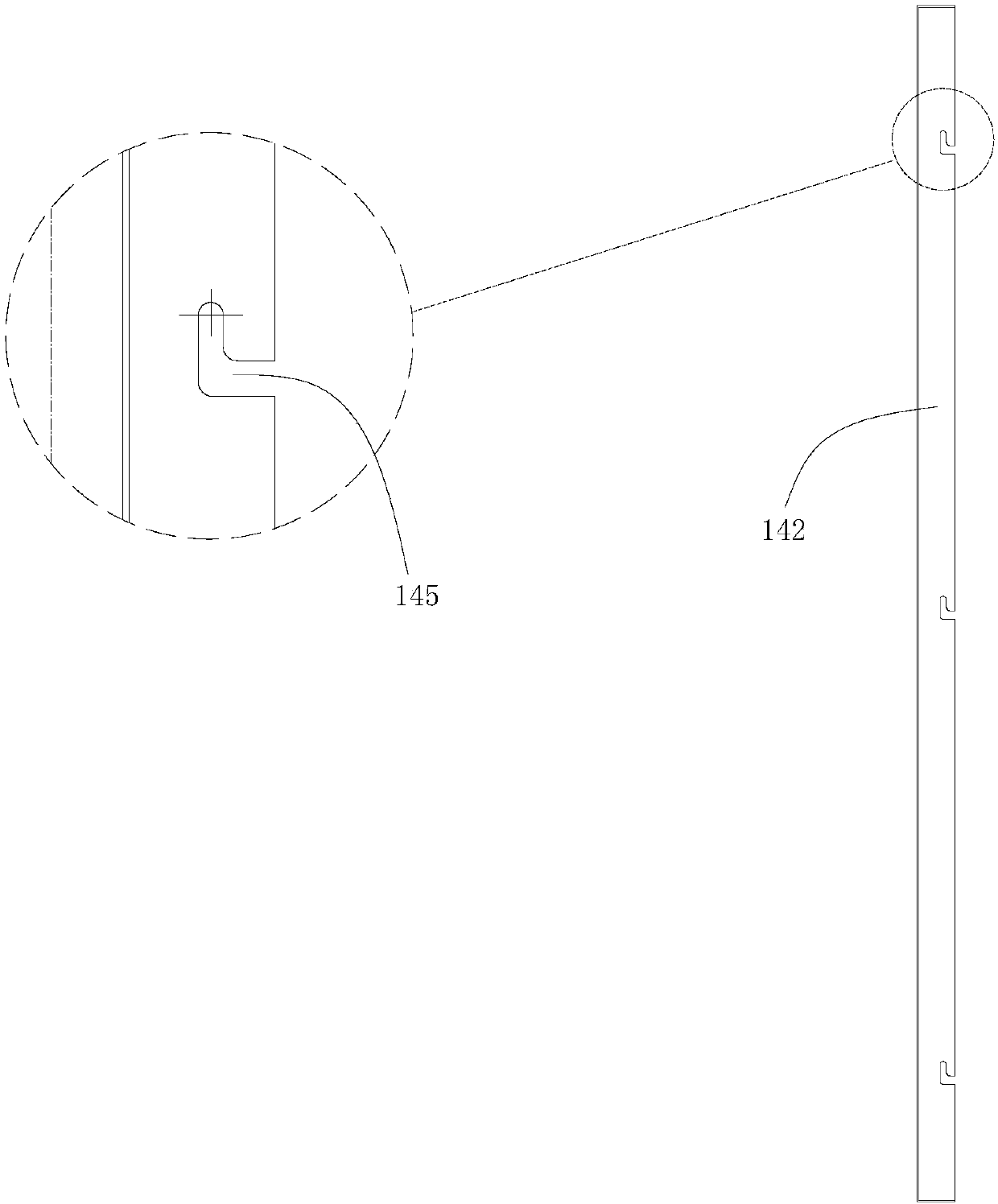

[0034] Such as fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com