A kind of composite type oilfield corrosion inhibitor and preparation method thereof

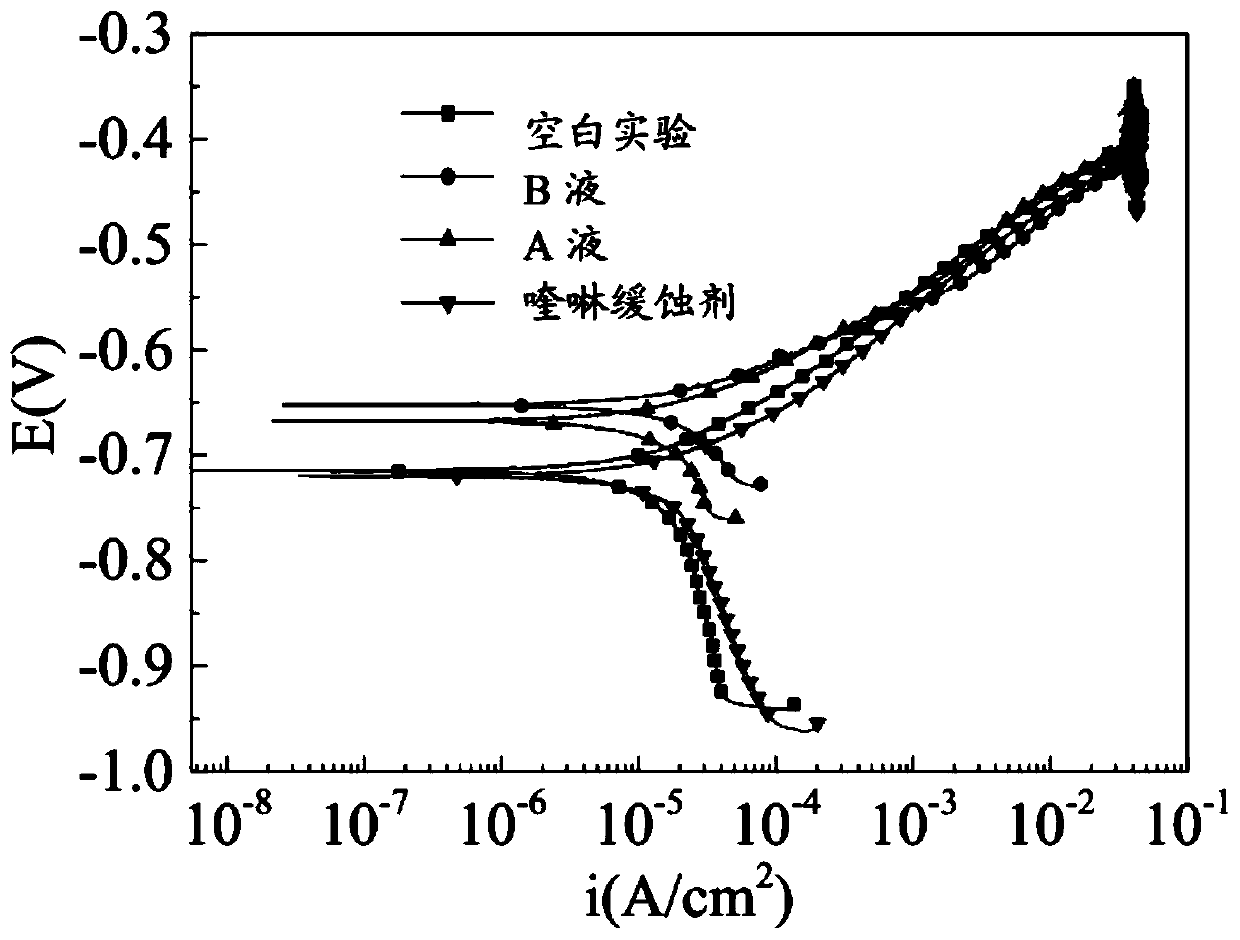

A corrosion inhibitor and oilfield technology, applied in the field of oilfield water treatment, can solve problems such as aggravated corrosion, failure to slow down oil-water pipeline corrosion, corrosion inhibitor failure, etc., to achieve the effect of delaying corrosion rate, facilitating large-scale promotion and application, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] According to another aspect of the present invention, the present invention provides a preparation method of a compound oilfield corrosion inhibitor, comprising the following steps:

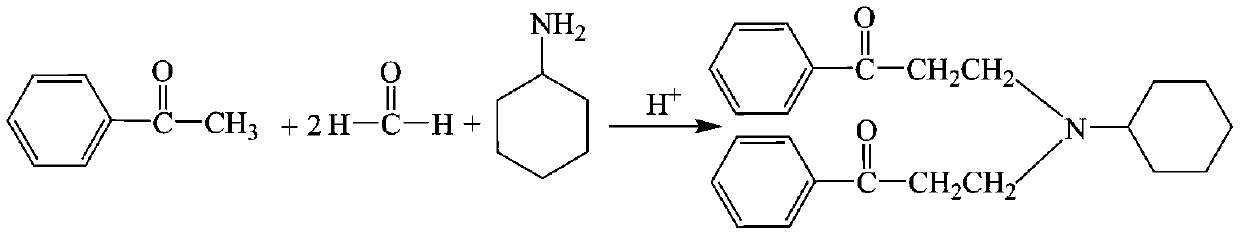

[0041] (1) Prepare liquid A

[0042] In the first reaction kettle, drop into the mixed solution of acetophenone and absolute ethanol, add hydrochloric acid dropwise while stirring, adjust the pH value of the solution to 2, and add dropwise formaldehyde and cyclohexylamine respectively at 80 ° C, the reaction is refluxed for 10 hours, adding A small amount of absolute ethanol was stirred to obtain a reddish-brown liquid, which was then compounded with potassium iodide and propargyl alcohol to obtain a Mannich corrosion inhibitor solution, and then added fatty alcohol polyoxyethylene ether and fatty alcohol polyoxyethylene ether phosphate at normal temperature and pressure, Prepare liquid A. Among them, the Mannich corrosion inhibitor A solution is a Mannich acidification corrosion inhibito...

Embodiment 1

[0057] (1) Preparation of liquid A:

[0058] Add 160 mL of absolute ethanol into a five-neck glass flask, add 47 mL of acetophenone, stir evenly, slowly add hydrochloric acid solution dropwise, and adjust the pH of the solution to 2. 68 mL of formaldehyde and 47 mL of cyclohexylamine were simultaneously added dropwise at about 80°C using a constant pressure dropping funnel, refluxed for 10 hours, a small amount of absolute ethanol was added, and the mixture was stirred evenly. Add 36g of potassium iodide and 80mL of propynyl alcohol to make A solution.

[0059] (2) Preparation of liquid B:

[0060] Put 146 grams of oleic acid and 206 grams of diethylenetriamine into another five-neck glass flask, stir evenly, and add 39 grams of xylene. Raise the temperature to 140-150°C and reflux for 4 hours. The temperature was raised to 180°C to evaporate xylene, and the temperature was continued to rise to 250°C for 4 hours. After that, the temperature was lowered to 120° C., 50 g of ...

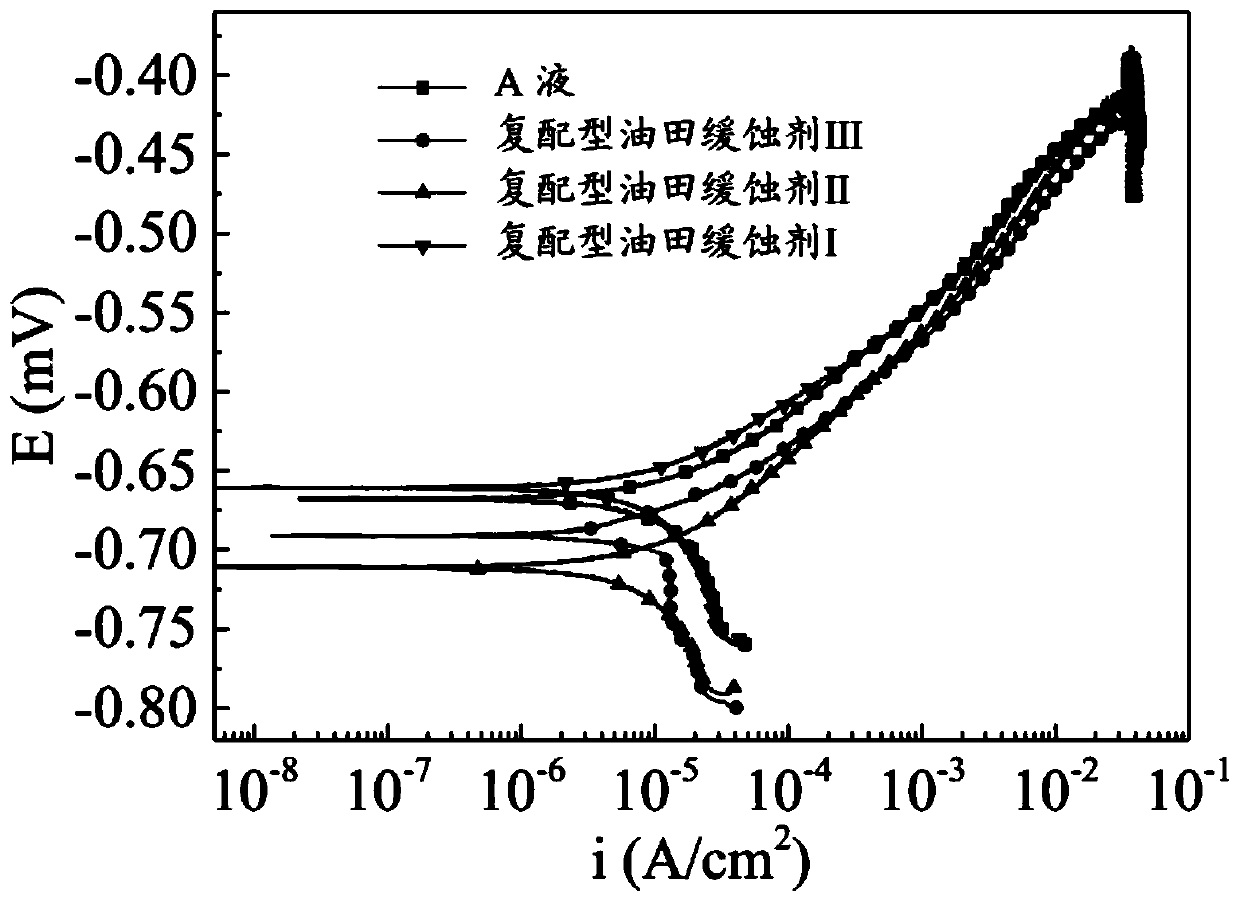

Embodiment 2

[0063] Adopt the same method as Example 1 to prepare A liquid and B liquid;

[0064] The A solution and the B solution are respectively compounded according to the volume ratio of 1:1 to obtain the compound oilfield corrosion inhibitor II.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com