Preparation method of corn porous starch

A technology of porous starch and corn, which is applied in the preparation of porous corn starch and the field of porous starch prepared by compound enzyme-intermittent ultrasonic method, which can solve the problems of long reaction time, slow reaction rate and high production cost, and achieve the reduction of enzyme consumption, Effect of avoidance of residual, high price advantage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

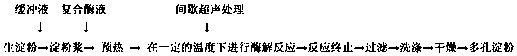

[0039] refer to figure 1 , the preparation method of corn porous starch, comprises the following steps:

[0040] (1) Prepare starch milk A: disperse 20 g of corn starch raw materials into citric acid and disodium hydrogen phosphate pre-buffer solution of pH 5.0, and prepare starch milk A with a mass concentration of 50%;

[0041] (2) Preheat treatment: move the starch milk A into a closed reactor with a stirrer and a condenser collection device, stir and heat to 50°C, keep for 15min, and the starch granules are heated to expand to obtain the starch milk B; ( 3) Enzymolysis treatment: add 0.4% by weight of glucoamylase compound enzyme (glucoamylase:α-amylase 9:1) to starch milk B, and perform enzymatic hydrolysis for 10 hours; among them, perform intermittent ultrasonication for 30 minutes during the enzymatic hydrolysis process Treatment, once every 30 minutes;

[0042] (4) Enzymolysis termination treatment: Immediately after enzymolysis, 4 mL of 4% NaOH solution was added t...

Embodiment 2

[0053] refer to figure 1 , the preparation method of corn porous starch, comprises the following steps:

[0054] (1) Preparation of starch milk A: disperse 20 g of corn starch raw materials into citric acid and disodium hydrogen phosphate pre-buffer solution of pH 3.5, and prepare starch milk A with a mass concentration of 30%;

[0055] (2) Preheat treatment: move starch milk A into a closed reactor with a stirrer and a condenser collection device, stir and heat to 45°C, keep for 20min, and the starch granules are heated to expand to obtain starch milk B; ( 3) Enzymolysis treatment: add 0.1% by weight of glucoamylase compound enzyme (glucoamylase: α-amylase 1:9) to starch milk B, and perform enzymatic hydrolysis for 5 hours; during the enzymatic hydrolysis process, perform intermittent ultrasonication for 20 minutes Treatment, once every 30 minutes;

[0056] (4) Enzymolysis termination treatment: Immediately after enzymolysis, 3.5 mL of 2% NaOH solution was added to terminat...

Embodiment 3

[0060] refer to figure 1 , the preparation method of corn porous starch, comprises the following steps:

[0061] (1) Preparation of starch milk A: disperse 20 g of corn starch raw materials into citric acid and disodium hydrogen phosphate pre-buffer solution of pH 5.5, and prepare starch milk A with a mass concentration of 40%;

[0062] (2) Preheat treatment: move starch milk A into a closed reactor with a stirrer and a condenser collection device, stir and heat to 55°C, keep for 5min, and the starch granules are heated to expand to obtain starch milk B; ( 3) Enzymolysis treatment: add 0.5% by weight of glucoamylase compound enzyme (glucoamylase:α-amylase 5:1) to starch milk B, and perform enzymatic hydrolysis for 8 hours; among them, perform intermittent ultrasonication for 25 minutes during the enzymatic hydrolysis process Treatment, once every 30 minutes;

[0063] (4) Enzymolysis termination treatment: Immediately after enzymolysis, 5 mL of 5% NaOH solution was added to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com