Straddling type monorail frame and assembly welding process method thereof

A process method and straddle-type technology, applied in the frame field of rail vehicle bogies, can solve the problems of structural asymmetry, unfavorable control of the overall size of the frame, large difference in welding volume and deformation size, etc., so as to improve work efficiency and product quality. The effect of huge control and improved frame size precision control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

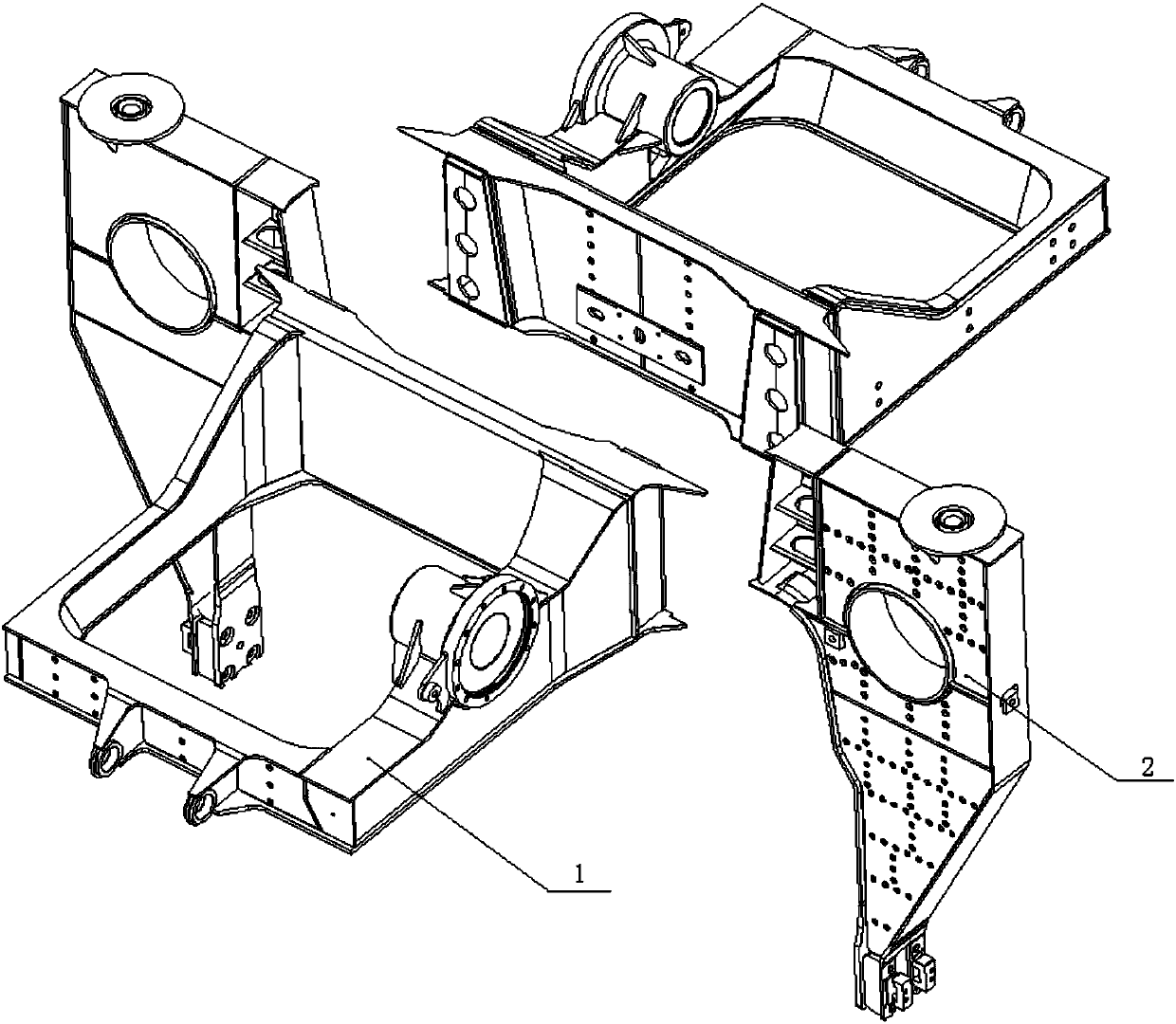

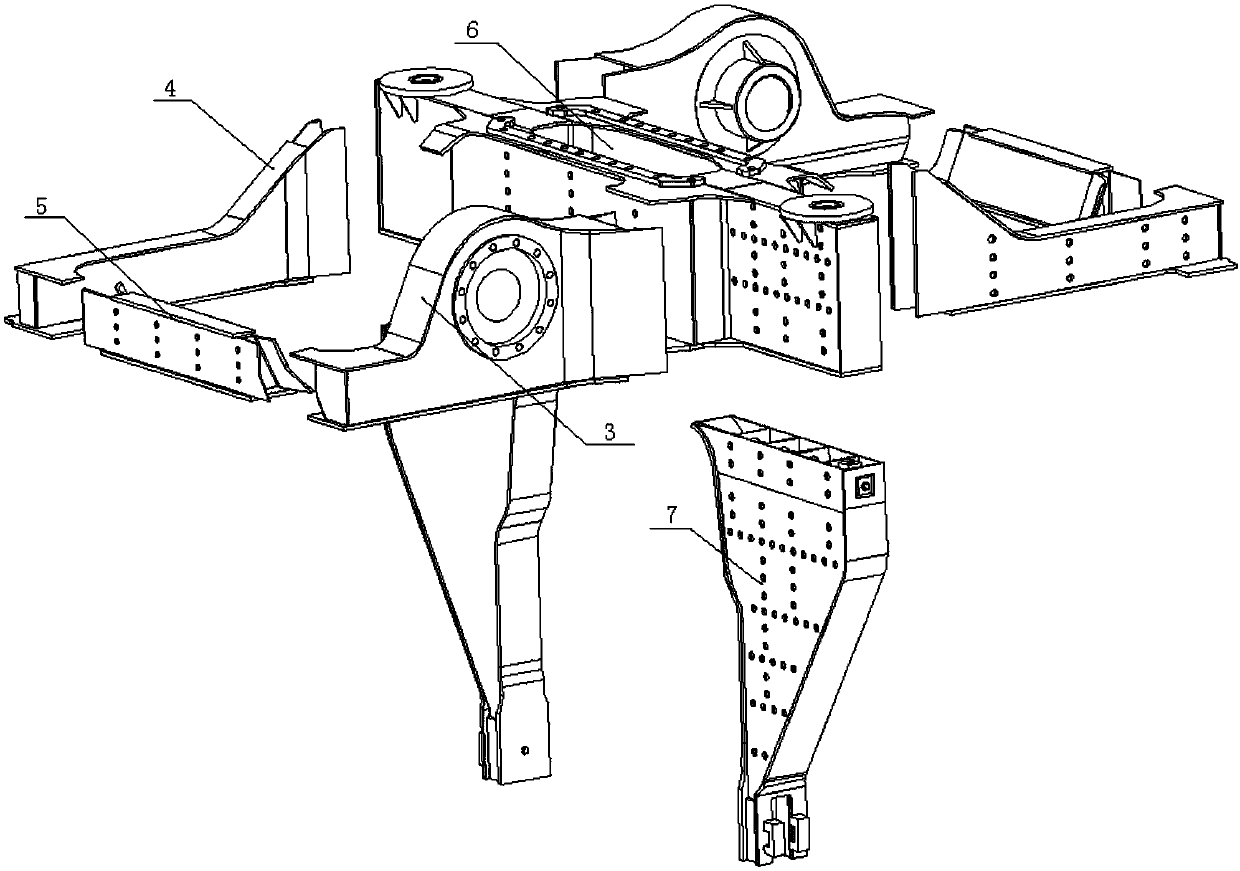

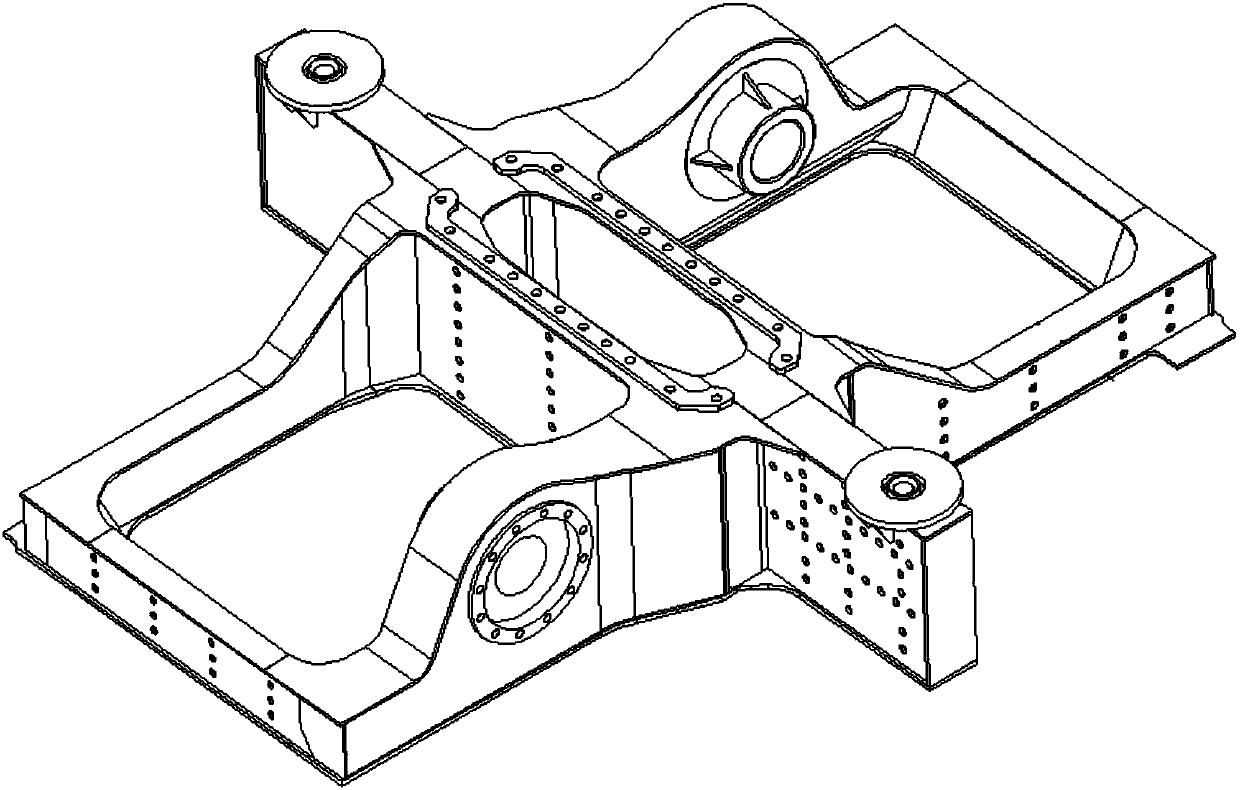

[0014] refer to figure 2 and image 3 , the straddle type monorail framework of the present invention is divided into 5 module parts altogether, is respectively wide side beam 3, narrow side beam 4, end beam 5, crossbeam 6, stable wheel 7, assembly welding process is as follows:

[0015] 1. The wide side beams, narrow side beams, end beams and cross beams are first assembled and welded into a large frame body: firstly fix the cross beams and end beams, then push the wide side beams and narrow side beams from the outside to the inside of the frame, and combine with the beams and The end beam is fixedly connected by plugging, and then the welding work of the above four parts is completed;

[0016] 2. Adjust and correct the large frame body that has been welded, and determine the process benchmarks of the X, Y, and Z axes of the workpiece;

[0017] 3. Assembling and welding the large frame body and the stabilizing wheels: first fix the large frame body, then assemble the two s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com