Regeneration method for adsorbent and flue gas purifying method

An adsorbent regeneration and adsorbent technology, which is applied in the directions of combustible gas purification, combustible gas purification/reformation, separation methods, etc., can solve the problems of shortening the adsorption operation time, rapid decline in the activity of the regenerated adsorbent, etc., so as to suppress the generation of elemental sulfur. , Easy to operate, easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0049] According to the first embodiment, all the reducing gas can be sent into the lifting section as the lifting medium, or part of the reducing gas can be sent into the lifting section as the lifting medium, and the remaining part of the reducing gas can be directly sent into the reduction reaction section bottom of. In the actual operation process, it can be selected according to the amount of the sulfide-adsorbed adsorbent, so that the amount of reducing gas used as the lifting medium is sufficient to lift the sulfide-adsorbed adsorbent to the reduction reaction section. From the perspective of further improving the effect of regeneration, the volume ratio of the reducing gas used as the lifting medium to the reducing gas directly sent to the bottom of the reduction reaction section is preferably 1:1-4, more preferably 1:1.5-3.5, further Preferably 1:2-3.

[0050] In the first embodiment, the temperature of the sulfide-adsorbed adsorbent entering the riser (ie, at the in...

Embodiment approach

[0088] By adopting the second embodiment, the reducing gas is contacted and reacted with the sulfide-adsorbed adsorbent, which can significantly reduce the pressure drop of the regeneration reactor while still obtaining better regeneration effect.

[0089] According to the regeneration method of the present invention, the reducing gas can be conventionally selected, whichever can reduce the sulfide adsorbed on the adsorbent. Generally, the reducing gas may be a gas commonly used in the field sufficient to reduce sulfides, and its specific examples may include but not limited to one or two or more of hydrogen, carbon monoxide, light hydrocarbons, and dry gases. The light hydrocarbon can be C 1 -C 5 alkanes, C 1 -C 5 olefins, preferably the C 1 -C 5 of alkanes. Specific examples of the light hydrocarbons may include, but are not limited to, one or more of methane, ethane, propane and its isomers, butane and its isomers, pentane and its isomers. The dry gas is preferably r...

Embodiment 1-7

[0119] The composition of the flue gas used in Examples 1-7 is as shown in Table 1, and the adsorbent used is fresh catalytic cracking catalyst (produced by Sinopec Qilu Catalyst Factory, model is MLC-500), and its composition and properties are listed in Table 2 out.

[0120] Table 1

[0121] components

SO x

NO x

N 2

O 2

h 2 o

CO 2

Content / Volume%

0.18

0.065

73.5

4.5

10

11.8

[0122] Table 2

[0123]

[0124] Among the examples 1-7, the mixed gas of hydrogen and argon is formulated into reducing gases with different hydrogen sulfide contents (as shown in Table 3) for regeneration, wherein the total content of hydrogen sulfide and hydrogen is 30% by volume, The content of hydrogen sulfide is shown in Table 3.

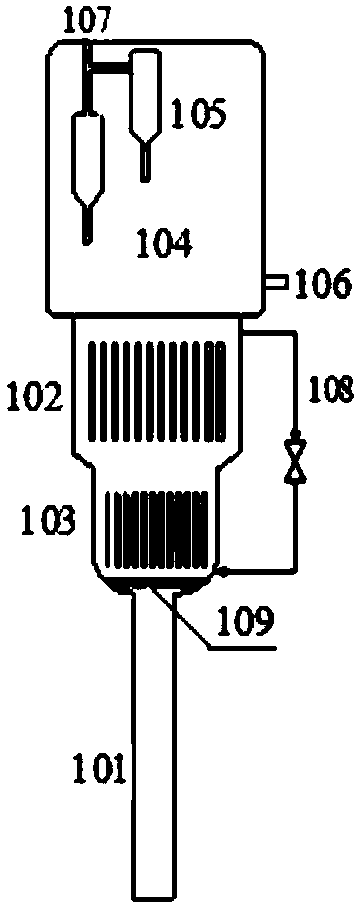

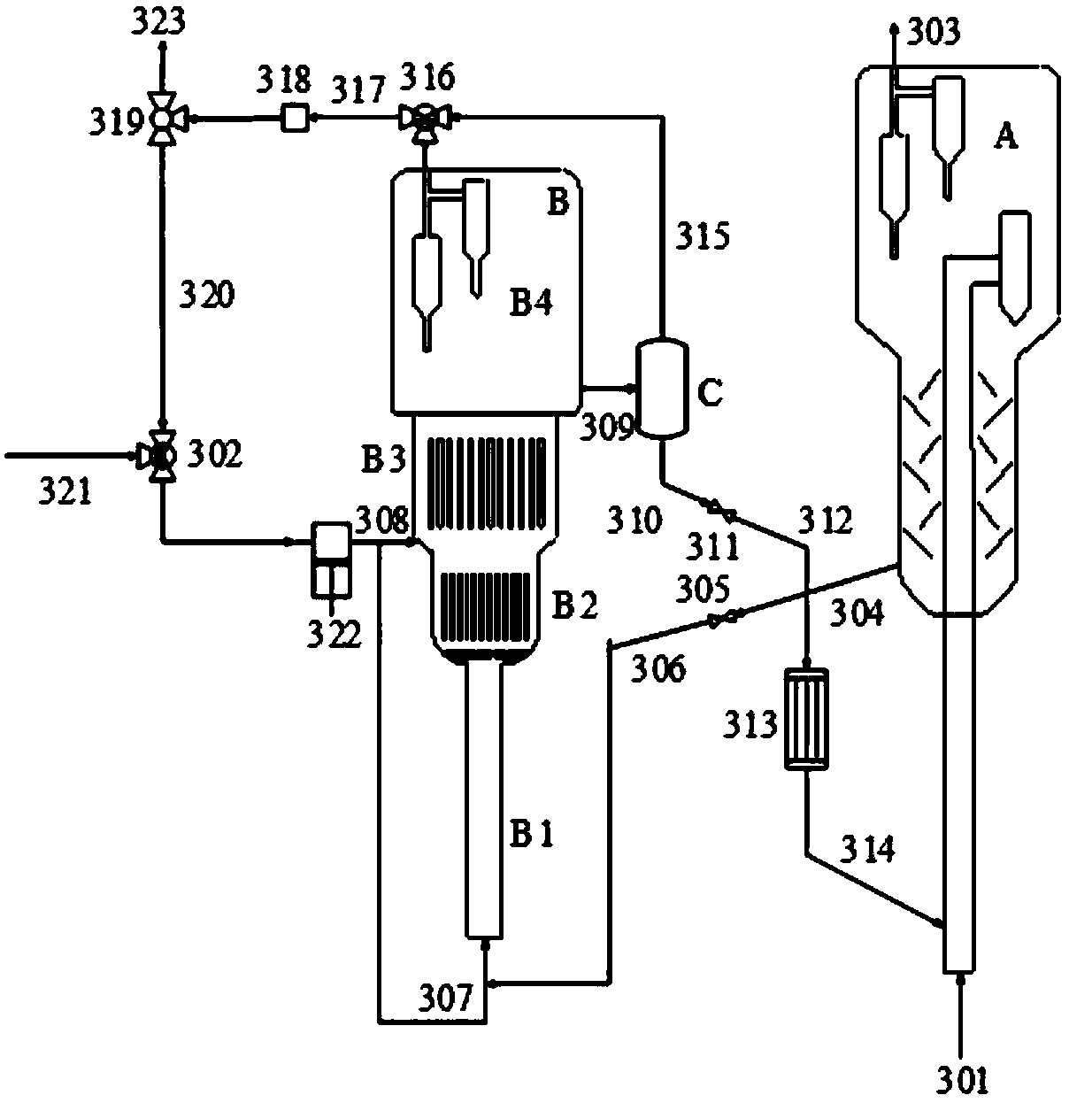

[0125] Embodiment 1-7 adopts figure 1 The regenerative reactor shown, the regenerative reactor includes a lifting section, a preheating section, a reduction reaction section, and a settling se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com