Aquatic feed feeding device

An aquatic feed and feeding tube technology, applied in fish farming, application, climate change adaptation and other directions, can solve the problems of inconvenient feeding, increased oxygen, high labor intensity, etc., and achieves easy throwing, wide angle and good effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

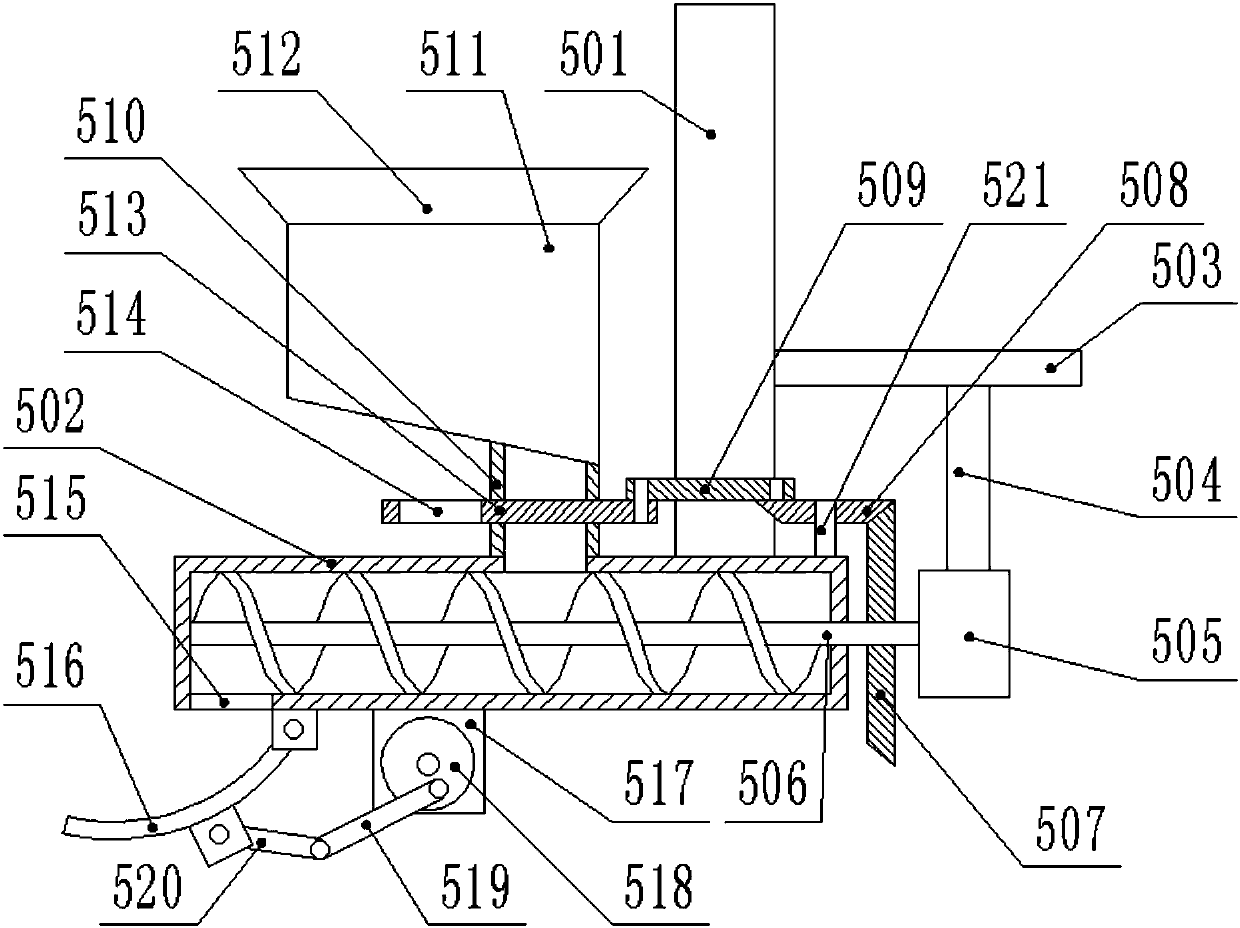

[0019] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, a kind of aquatic feed feeding device comprises a slide bar 1, the slide bar 1 is covered with a slide block 2 and is slidably connected with it, the lower end of the slide block 2 is fitted with a rotating plate 8, and the rotating plate 8. An annular rotating disk 3 is fixed on the upper end. The section of the annular rotating disk 3 is "T" shaped. The lower end of the slider 2 is provided with a chute matching the annular rotating disk 3. The annular rotating disk 3 The slider 2 is embedded with a motor A4, the output shaft of the motor A4 passes through the rotating plate 8 and is fixed to it, and the thrower 5 and the aerator are arranged under the rotating plate 8 6. The thrower 5 also includes a connecting rod 501, the upper end of which is fixed to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com