LED lamp power supply connection structure of backlight module group

A technology for LED lamp and power supply connection, which is applied in the field of LED lamp power supply connection structure, can solve problems such as light spots, and achieve the effect of saving costs and ensuring production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

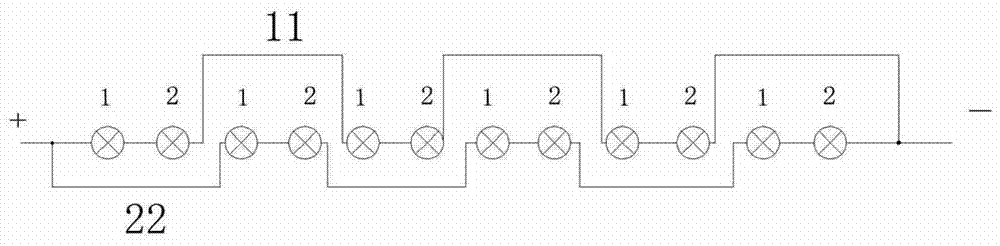

Embodiment 1

[0021] In this embodiment, LED lamps with 2 different light colors are used, and there are 2 power supply lines in total, as shown in the attached figure 1 As shown, in this embodiment, the power supply line 11 and the power supply line 22 are in a parallel structure, LED lights of different light colors are arranged alternately at equal intervals, and every 2 LED lights are used as a light unit. In this embodiment, there are 6 light units in total. The power supply line 11 and the power supply line 22 are alternately connected to the lamp units, that is, the power supply line 11 is connected to the 1st, 3rd, and 5th lamp units, and the power supply line 22 is connected to the 2nd, 4th, and 6th lamp units. Equipped with the same light color and the same number of LED lights on average, and finally the negative ends of the power supply lines are connected together to complete the design of the power supply mechanism for a horizontal row of LED lights.

[0022] Power is supplied...

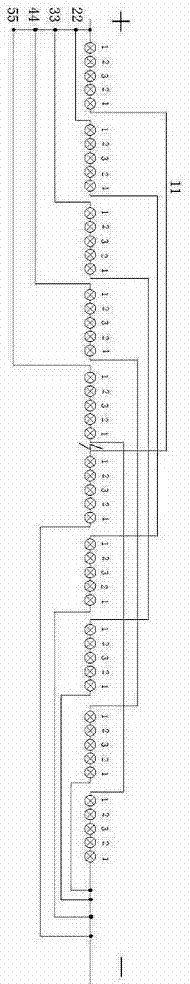

Embodiment 2

[0024] In this embodiment, LED lamps with 3 different light colors are used, and there are 5 power supply lines in total, among which there are 5 integral multiples of lamp units, such as figure 2 As shown, because the LED lamps match the color gamut design, the lamp units in this embodiment are arranged as 12321, sharing LED lamps with 3 different light colors, but the number of LED lamps contained in each group of lamp units 5. The 5 power supply lines are alternately connected to different lamp units, and the power supply line 11 is connected to the 1st, 6th, 11th, etc. (that is, the 5n+1th light unit, n is an integer), and so on. The 5n+2th light unit is connected, the power supply line 33 is connected to the 5n+3th light unit, the power supply line 44 is connected to the 5n+4th light unit, and the power supply line 55 is connected to the 5th (n+1) light unit. Because the number of light units in this implementation is an integral multiple of 5, the same number of light u...

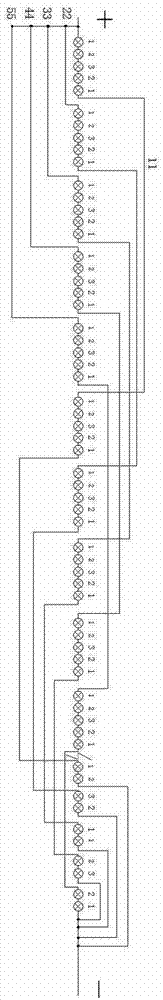

Embodiment 3

[0027] In this embodiment, similar to Embodiment 2, the difference is that the number of lamp units is an integer multiple of 5 plus 2, because the last two lamp units cannot be equally divided into each power supply line, so the two lamp units The LED lights in the unit are split, there are 10 LED lights in the two light units, and the 5 power supply lines are alternately connected to the LED lights. The specific connection method is that the 10 LED lights are numbered from 1, and the power supply line 11 is connected to the 6th, (that is, the 5n+1th LED light, n is an integer), and so on, the power supply line 22 is connected to the 5n+2 LED light, the power supply line 33 is connected to the 5n+3 LED light, and the power supply line is connected to the 5n+2 LED light. 44 is connected to the 5n+4th LED light, and the power supply line 55 is connected to the 5th (n+1) LED light. That is to disassemble the redundant lamp unit, so that the distribution of LED lamps on different...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com