Self-stacking manufacturing process of punched sheet body

A manufacturing process and sheet technology, which is applied in the field of punching sheet self-stacking manufacturing technology, can solve the problems of affecting the service life of laser welding equipment, expensive laser welding equipment, and limiting production efficiency, so as to improve motor efficiency, The effect of improving utilization rate and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

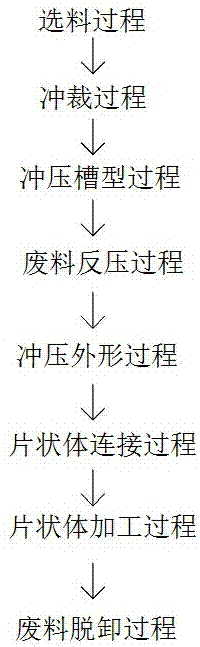

[0023] Example 1: as figure 1 A self-stacking manufacturing process of a blanking sheet body is shown, and the manufacturing process includes the following steps: firstly, a material selection process is performed, and raw materials are selected according to the processing requirements of the workpiece; The sheet body of the workpiece needs to be processed; then punch the groove shape, and transport the sheet body to the stamping die I. According to the requirements of the groove shape in the sheet body, punch the groove shape in the sheet body, and the groove shape can be circular Shape or oval or square; it can also be irregular shape, and part of the waste punched out of the groove is discharged, part of it is left in the die, and part of the waste left in the die is spaced apart from each other; The waste in the die is back pressed into the groove with stamping parts, so that the waste is connected with the sheet body; that is, the waste is punched back into the groove of ...

Embodiment 2

[0025] Example 2: A self-stacking manufacturing process of a blanked sheet body. The other processes are the same as those of Example 1, but during the connection process of the sheet body, the waste is punched back into the groove shape of the sheet body, and the surface of the waste is The surface of the sheet body is the same plane, and then the connecting piece is punched in the waste, and the two adjacent pieces of waste are connected to each other by the connecting piece. For example, when the first sheet body and the second sheet body are superimposed, the connecting piece makes the The waste material of the first sheet is fixedly connected with the waste material of the second sheet, so that the sheet body of the first sheet and the sheet body of the second sheet are connected together. As a further improvement measure of the present invention, in the scrap, the concave part and the convex part are punched, and the concave part and the convex part of the two adjacent sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com