Carbon fiber cloth surface modification method for flexible supercapacitor electrode

A technology of supercapacitor and surface modification, which is used in the manufacture of hybrid capacitor electrodes and hybrid/electric double layer capacitors. It can solve the problems of poor cycle stability, low capacitance performance and limited electrode material performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

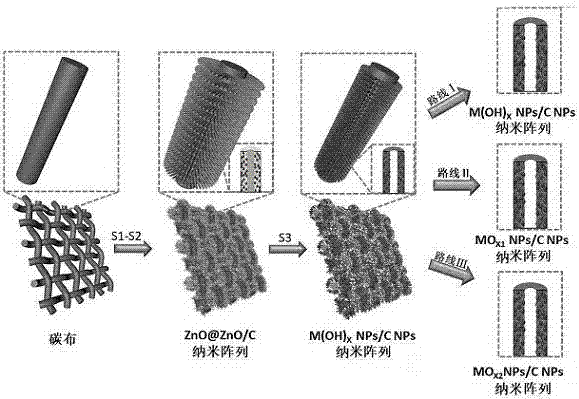

[0048] The invention provides a carbon cloth surface modification method for flexible supercapacitor electrodes, refer to the attached figure 1 Route I in includes the following steps:

[0049] S1: First arrange carbon in a mixed solution formed by 0.4g zinc nitrate hexahydrate, 0.2g hexamethylenetetramine and 70mL deionized water, control the temperature at 90°C for 12h, and prepare carbon containing ZnO nanoarrays cloth, and then repeatedly washed three times with deionized water and ethanol, and dried at a controlled temperature of 60 ° C for 10 h;

[0050] S2: Arrange the carbon containing ZnO nanoarray prepared in S1 in a mixed solution formed by 0.2g 2-methylimidazole, 12mL dimethylformamide and 4mL deionized water, and control the temperature at 70°C for 10h to prepare The carbon cloth containing ZnO@ZIF-8 nanoarrays was obtained, and then repeatedly washed with deionized water and ethanol three times, dried at a controlled temperature of 70 °C for 12 h, and then heate...

Embodiment 2

[0054] The invention provides a carbon cloth surface modification method for flexible supercapacitor electrodes, refer to the attached figure 1 Route II in includes the following steps:

[0055] S1: First arrange carbon in a mixed solution formed by 0.4g zinc nitrate hexahydrate, 0.2g hexamethylenetetramine and 70mL deionized water, control the temperature at 90°C for 12h, and prepare carbon containing ZnO nanoarrays cloth, and then repeatedly washed three times with deionized water and ethanol, and dried at a controlled temperature of 60 ° C for 10 h;

[0056] S2: Arrange the carbon containing ZnO nanoarray prepared in S1 in a mixed solution formed by 0.2g 2-methylimidazole, 12mL dimethylformamide and 4mL deionized water, and control the temperature at 70°C for 10h to prepare The carbon cloth containing ZnO@ZIF-8 nanoarrays was obtained, and then repeatedly washed with deionized water and ethanol three times, dried at a controlled temperature of 70 °C for 12 h, and then heat...

Embodiment 3

[0062] The invention provides a carbon cloth surface modification method for flexible supercapacitor electrodes, refer to the attached figure 1 Route III in includes the following steps:

[0063] S1: First arrange carbon in a mixed solution formed by 0.4g zinc nitrate hexahydrate, 0.2g hexamethylenetetramine and 70mL deionized water, control the temperature at 90°C for 12h, and prepare carbon containing ZnO nanoarrays cloth, and then repeatedly washed three times with deionized water and ethanol, and dried at a controlled temperature of 60 ° C for 10 h;

[0064] S2: Arrange the carbon containing ZnO nanoarray prepared in S1 in a mixed solution formed by 0.2g 2-methylimidazole, 12mL dimethylformamide and 4mL deionized water, and control the temperature at 70°C for 10h to prepare The carbon cloth containing ZnO@ZIF-8 nanoarrays was obtained, and then repeatedly washed with deionized water and ethanol three times, dried at a controlled temperature of 70 °C for 12 h, and then hea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com