Three-dimensional laser measurement lifting platform

A lifting platform and three-dimensional laser technology, applied in the field of surveying and mapping instruments, can solve the problems of sparse point cloud density, the lifting platform cannot meet the lifting system, and the scanner center and the surface measurement point cannot be located on the same plumb line, etc. Work efficiency, the effect of reducing scanning workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

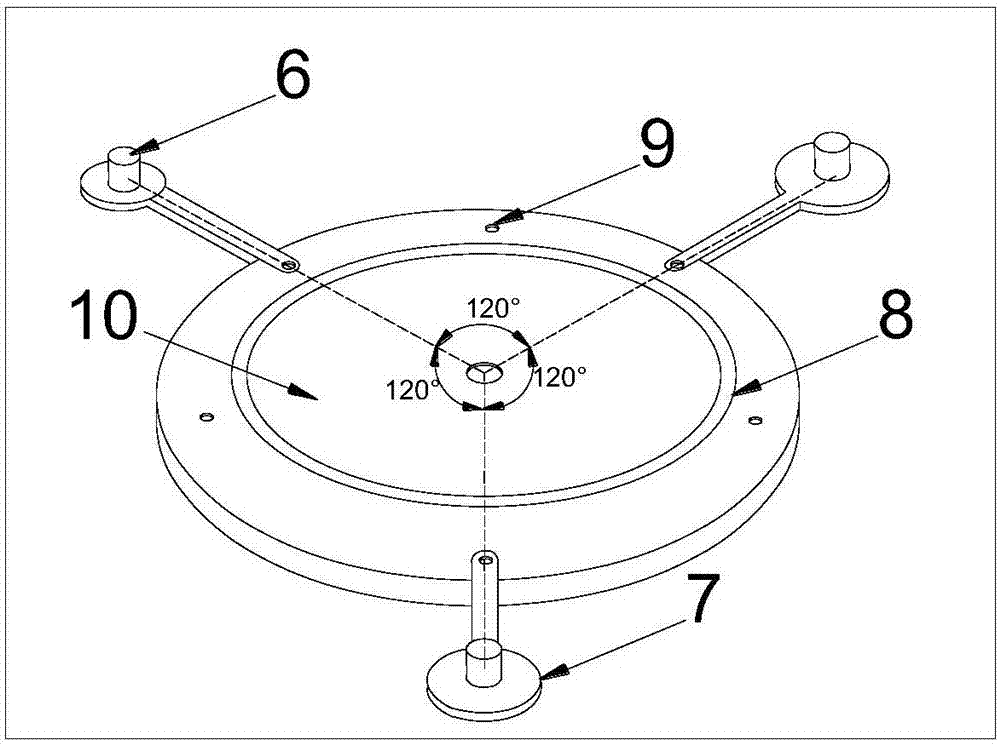

Embodiment example 1

[0054] When using the 3D laser scanner in the field, first of all, according to the position of the observation point on the ground surface and the flatness of the ground where the instrument is erected, the mid-sole plate 5 will be strictly centered, and the lower pillars will be adjusted for roughly leveling, and then the cylinder-type lifting main body 4 is placed on the centering base plate 5, and finally the mobile centering module 3, the leveling module 2, the laser projection module 1 and the three-dimensional laser scanner are installed above the cylinder type lifting main body 4 in sequence from bottom to top.

[0055] After the installation is completed, use the air pump to inflate the air so that the internal air pressure of the cylinder type lifting body 4 is higher than the external air pressure. Under the effect of the internal and external pressure difference, the instrument is lifted, and the inflation is stopped when the required lifting height is reached.

[0...

Embodiment example 2

[0060] The operation steps are similar to the implementation case 1, only the leveling module uses the human-computer interactive leveling device, the specific operation is as follows:

[0061] On the ground, the staff manually adjust the rotation of the three spin motors through the operating system to level the T-shaped distribution of air bubbles. The process is to first start the two motors parallel to the tube vial to adjust the height of the foot screws (rotate in opposite directions, that is, rotate inward or outward at the same time), so that the bubble of the tube level a14 is centered, and adjust the height of the third foot screw. Center the bubble of the vial b15.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com