Piston mounting structure for forklift portal inclined oil cylinder

A technology for tilting oil cylinders and forklift masts. It is applied in the direction of lifting devices and fluid pressure actuating devices. It can solve the problem of coaxiality difference between the seal groove and the piston rod and the inner hole of the cylinder barrel, which affects the sealing performance of the seal and parts. and the difficulty of structural design, etc., to achieve the effect of compact structure, convenient maintenance and replacement, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

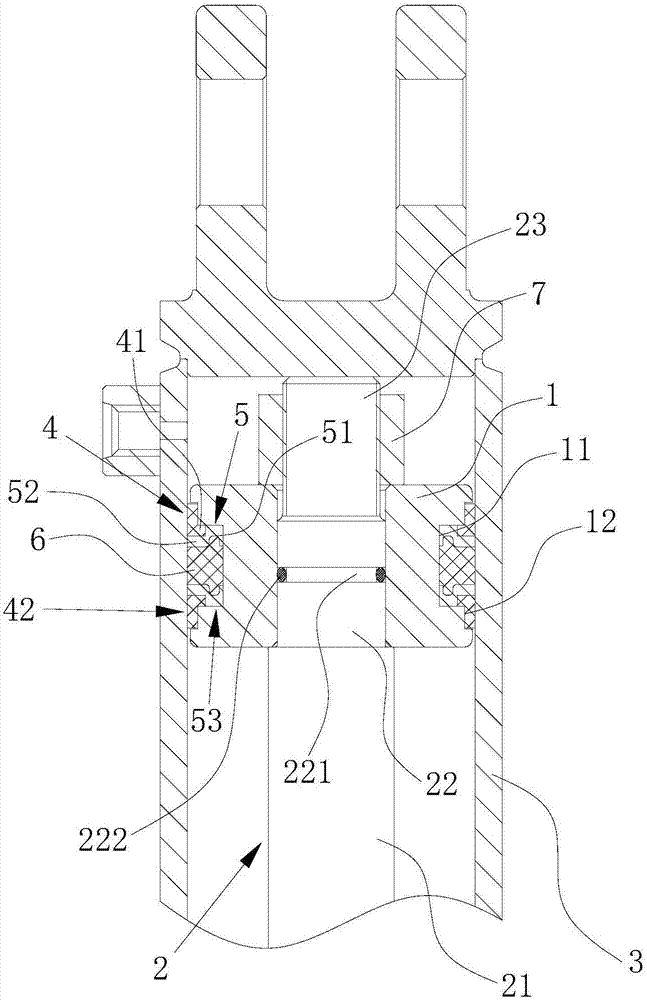

[0023] see figure 1 , the installation structure includes a piston 1, a piston rod 2 and a cylinder 3, the piston 1 is arranged on the piston rod 2, and the piston 1 and the piston rod 2 move axially in the cylinder 3;

[0024] The outer wall of the piston 1 is provided with a first annular groove 11 and a second annular groove 12 which communicate with the inside and outside and whose groove width increases;

[0025] The guide cylinder 4, protection cylinder 5, first sealing ring 6, another protection cylinder 5, and another guide cylinder 4, which are stacked sequentially from bottom to top and socketed with the piston 1, are filled in the piston 1 and the cylinder. between 3;

[0026] The structures and specifications of the guide cylinder 4 and the other guide cylinder 42 are respectively the same, and both are arranged symmetrically with respect to the first sealing ring 6;

[0027] The structures and specifications of the protection cylinder 5 and another protection cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com