Claw-sleeve type multi-stage cementing device

A technology of graded cement injectors and claw sleeves, which is applied in wellbore/well components, earthwork drilling, sealing/isolation, etc., and can solve problems such as complex assembly process, unstable product performance, and complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the following embodiments in no way limit the present invention.

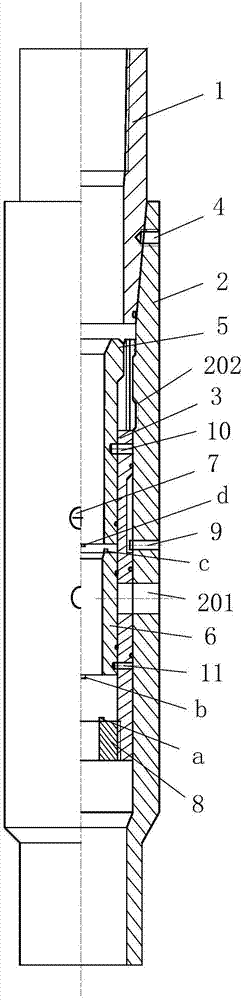

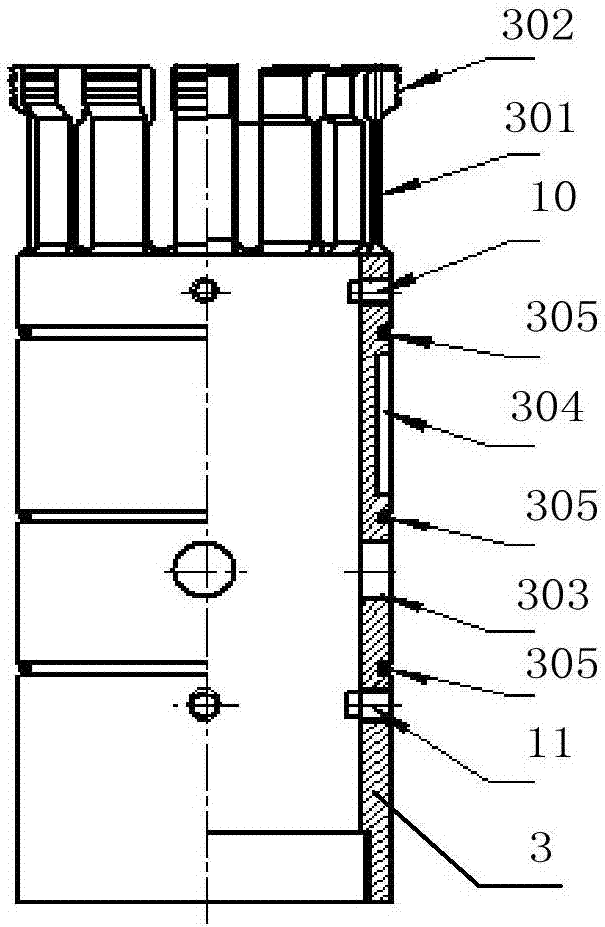

[0024] Such as figure 1 As shown, the claw-type step-by-step cementing device includes an upper joint 1, a cylindrical body 2, a sliding sleeve 3 fitted inside the cylindrical body 2, and closing sleeves that are sequentially fitted inside the sliding sleeve 3 and arranged at intervals from top to bottom. 5. Open the sleeve 6 and the anti-rotation sleeve 8; where,

[0025] The upper joint 1 is threaded on the top inner wall of the cylindrical body 2, and the cylindrical body 2 is fixed on the upper joint 1 by a plurality of fastening screws 4 arranged on the outer wall along the circumferential direction to prevent tripping; on the upper joint 1 The inner wall is provided with connecting internal threads for connecting casing strings; the inner diameter of the upper joint 1 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com