Biodegradable polyester composition

A biodegradable polyester and biodegradable technology is applied in the field of biodegradable polyester compositions to achieve the effects of excellent food contact performance, improvement of poor winding, and excellent winding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

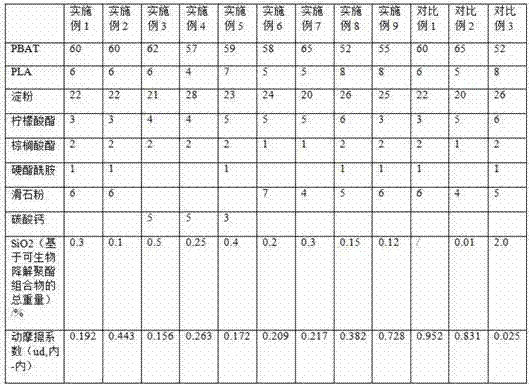

Embodiment 1-9 and comparative example 1-3

[0038] According to the formula shown in Table 1, mix PBAT, PLA, starch, inorganic filler, plasticizer, surfactant, wax and silicon dioxide, put them into a single-screw extruder, extrude at 140°C-240°C, Granulating to obtain a biodegradable polyester composition. The performance test data are shown in Table 1.

[0039] Performance evaluation method:

[0040] Evaluation method of biodegradable polyester composition film winding performance (dynamic friction coefficient, ud, inner-inner): (dynamic friction coefficient meter MXD-02, Jinan Languang Electromechanical Technology Co., Ltd.) using a test plate (placed in the horizontal operation on the platform), one biodegradable polyester composition sample is fixed on the test board with double-sided tape or other means, and the other biodegradable polyester composition sample is cut properly and fixed on the special slide board, and then Place the slide plate on the center of the first sample on the test plate according to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com