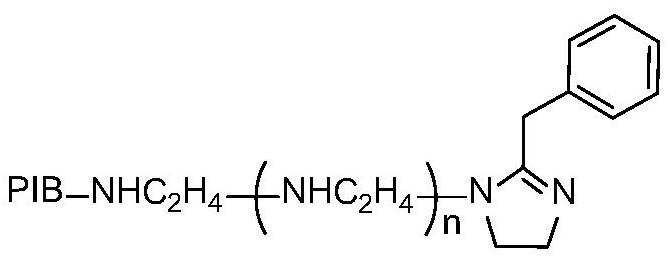

A kind of aryl imidazoline modified polyisobutenyl amine dispersant

A technology of polyisobutylene amine and aryl imidazoline, which is applied in the direction of fuel additives, fuels, liquid carbon-containing fuels, etc., can solve problems such as adverse effects of catalysts, loss of effect of scale inhibitors, loss of application effects, etc., and achieve good scale removal effect , saving energy and resources, excellent high temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

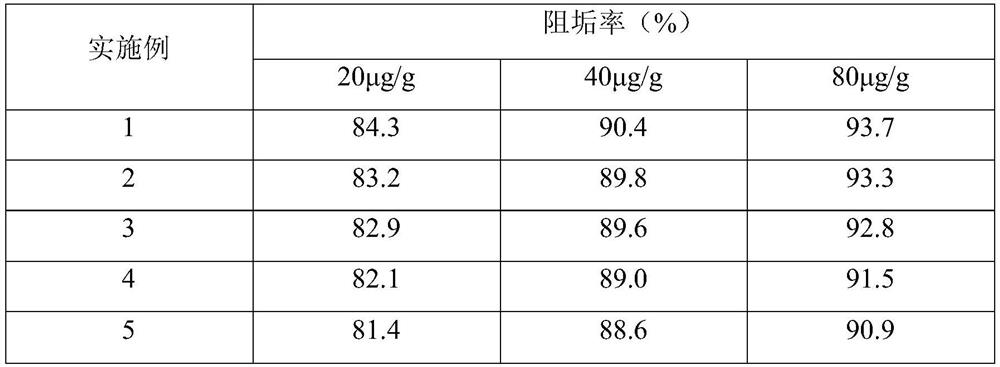

Examples

Embodiment 1

[0030] The preparation method of the polyisobutylene amine dispersant modified by aryl imidazoline comprises the following steps:

[0031] (1) Add 100g of phenylacetic acid and 167g of tetraethylenepentamine into the reactor respectively, then add 60g of xylene as solvent and water-carrying agent, pass in nitrogen, first react at 140°C for 4h to obtain amide, and then raise the temperature to 210°C React for 2.5 hours to carry out cyclodehydration, during which the water generated by the reaction is separated, and the unreacted raw materials are removed by rotary evaporation to obtain benzyl imidazoline;

[0032] (2) Add 500g of polyisobutene with a molecular weight of 500-2000 and a terminal double bond rate greater than 80% and 250g of n-heptane into the reactor, add an acidic ion exchange resin as a catalyst, and then add 25g of acetic acid, within 3 hours at 80°C Add 100g of hydrogen peroxide dropwise, keep the temperature for 6 hours, wash with water until neutral, and sp...

Embodiment 2

[0035] The preparation method of the polyisobutylene amine dispersant modified by aryl imidazoline comprises the following steps:

[0036] (1) Add 100g of phenylacetic acid and 167g of tetraethylenepentamine into the reactor respectively, then add 60g of xylene as solvent and water-carrying agent, pass in nitrogen, first react at 160°C for 3h to obtain amide, and then heat up to 220°C The reaction was carried out for 2 hours by cyclodehydration, during which the water generated by the reaction was separated, and the unreacted raw materials were removed by rotary evaporation to obtain benzyl imidazoline;

[0037] (2) Add 500g of polyisobutene with a molecular weight of 500-2000 and a terminal double bond rate greater than 80% and 250g of n-heptane into the reactor, add acidic ion exchange resin as a catalyst, and then add 25g of acetic acid, and heat it at 90°C within 2 hours Add 100g of hydrogen peroxide dropwise, keep the temperature for 5 hours, wash with water until neutral...

Embodiment 3

[0040] The preparation method of the polyisobutylene amine dispersant modified by aryl imidazoline comprises the following steps:

[0041] (1) Add 100g of phenylacetic acid and 167g of tetraethylenepentamine into the reactor respectively, then add 60g of xylene as solvent and water-carrying agent, pass in nitrogen, first react at 130°C for 6h to obtain amide, and then heat up to 200°C The reaction was carried out for 3 hours by cyclodehydration, during which the water generated by the reaction was separated, and the unreacted raw materials were removed by rotary evaporation to obtain benzyl imidazoline;

[0042](2) Add 500g of polyisobutene with a molecular weight of 500-2000 and a terminal double bond rate greater than 80% and 250g of n-heptane into the reactor, add acidic ion exchange resin as a catalyst, and then add 25g of acetic acid, within 3 hours at 70°C Add 100g of hydrogen peroxide dropwise, keep the temperature for 8 hours, wash with water until neutral, and spin of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com