Force reduction mechanism of winch

A winch, integrated technology, applied in the direction of the spring mechanism, mechanical equipment, transmission parts, etc., can solve the problems of huge and cumbersome structure, does not meet the operating requirements, etc., achieve small volume, optimize space utilization, and good interchangeability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0037] In order to further illustrate the technical solution of the present invention and the technical effects brought by it, in conjunction with the accompanying drawings, the specific implementation of the present invention is as follows:

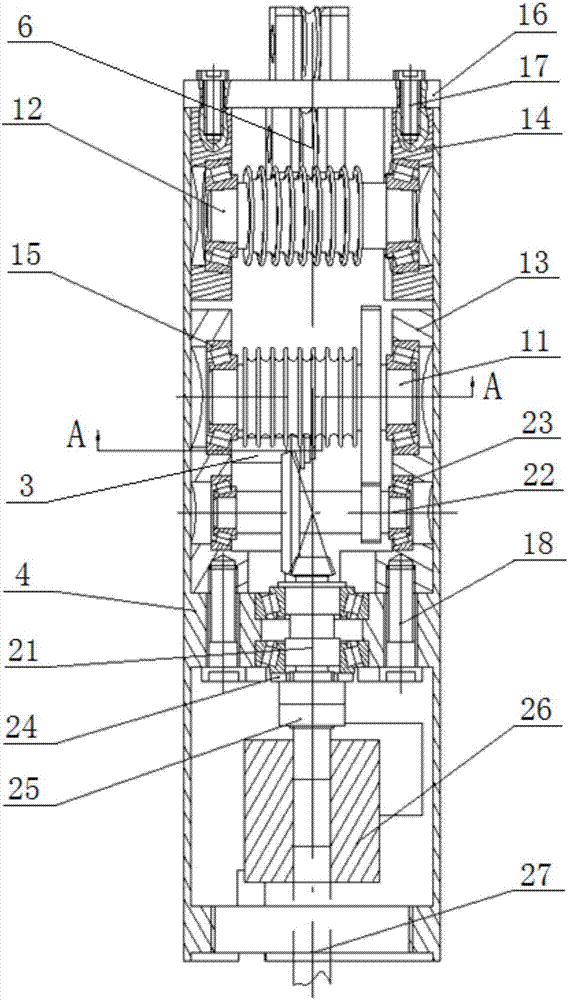

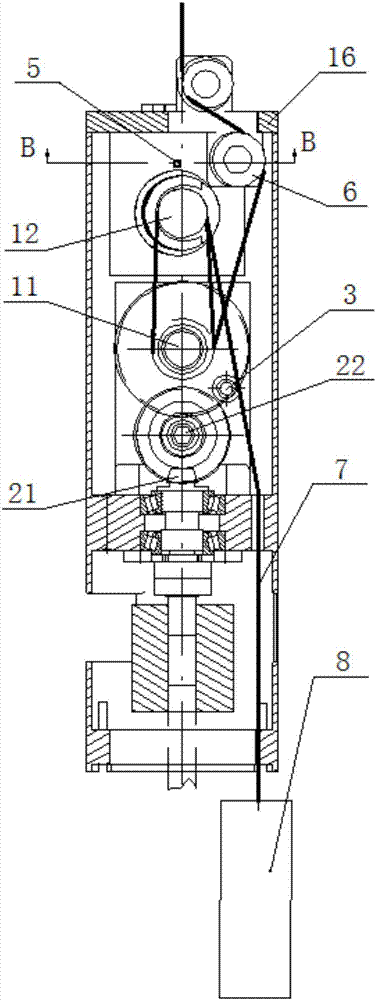

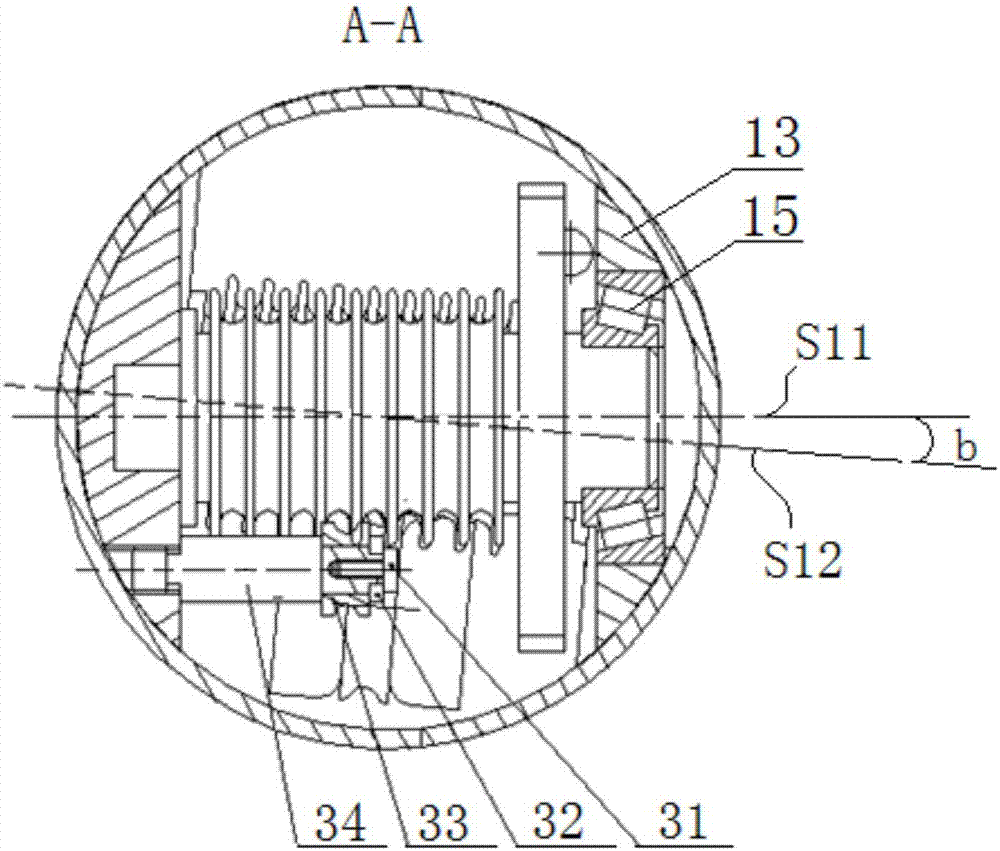

[0038] The present invention provides a thin cylindrical drawworks force reduction mechanism with small volume and large load, such as figure 1 As shown, the drawworks force reduction mechanism of the present invention is mainly composed of a driving bevel gear shaft 21, a transmission gear shaft 22, a lower sheave shaft 11, an upper sheave shaft 12, an upper guide wheel assembly 6, a lower guide wheel assembly 3, a housing 4 and Upper cover plate 16 is formed.

[0039] Described housing 4 is a cylinder shape, is provided with upper and lower two cavities, and above-mentioned transmission gear shaft 22, lower sheave shaft 11, upper sheave shaft 12, some components in upper guide wheel assembly 6 and lower guide wheel The components 3 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com