Paint spraying equipment for wood production

A paint spraying equipment and wood technology, applied in the direction of spraying device, liquid spraying device, etc., can solve the problems of poor spraying effect, easy flying of paint, time-consuming and other problems, and achieve good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

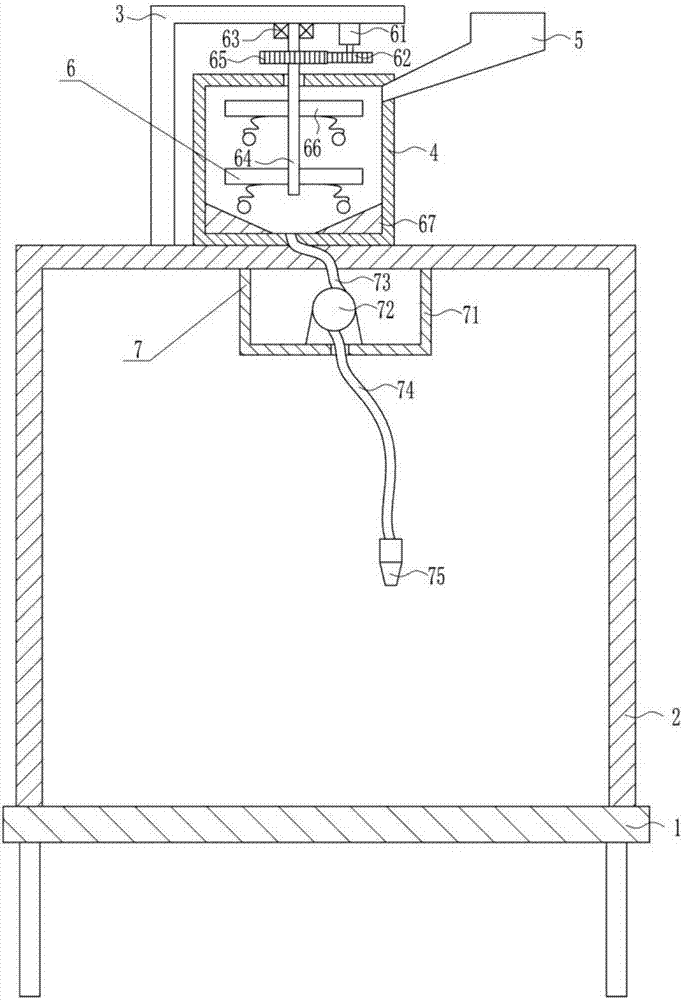

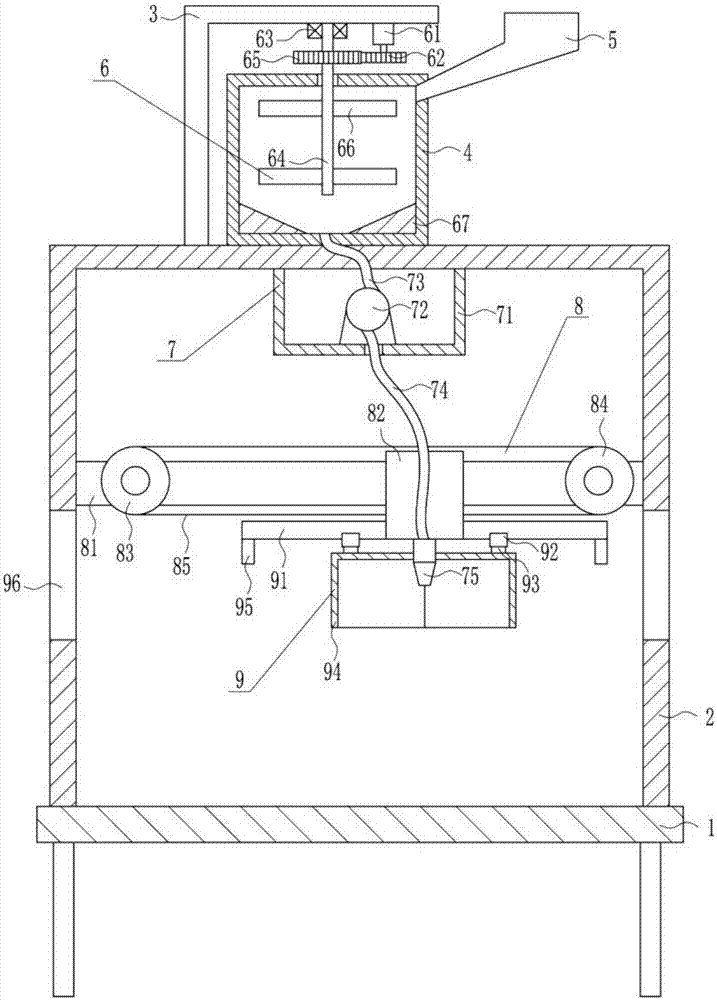

[0030] A paint spraying equipment for wood production, such as Figure 1-4 As shown, it includes a workbench 1, an n-type frame 2, a 7-type plate 3, a box body 4, a lower hopper 5, a stirring device 6 and a paint spraying device 7. The top of the workbench 1 is installed with an n-type frame 2, and the n-type frame 2 A 7-type plate 3 is installed on the top, a box 4 is installed in the middle of the top of the n-type frame 2, a lower hopper 5 is installed on the upper part of the right side of the box 4, and the lower hopper 5 is communicated with the box 4. There is a stirring device 6 , the stirring part of the stirring device 6 is located in the box 4 , and a paint spraying device 7 is arranged in the middle of the top of the n-shaped frame 2 .

Embodiment 2

[0032] A paint spraying equipment for wood production, such as Figure 1-4 As shown, it includes a workbench 1, an n-type frame 2, a 7-type plate 3, a box body 4, a lower hopper 5, a stirring device 6 and a paint spraying device 7. The top of the workbench 1 is installed with an n-type frame 2, and the n-type frame 2 A 7-type plate 3 is installed on the top, a box 4 is installed in the middle of the top of the n-type frame 2, a lower hopper 5 is installed on the upper part of the right side of the box 4, and the lower hopper 5 is communicated with the box 4. There is a stirring device 6 , the stirring part of the stirring device 6 is located in the box 4 , and a paint spraying device 7 is arranged in the middle of the top of the n-shaped frame 2 .

[0033]The stirring device 6 includes a first motor 61, a first gear 62, a first bearing seat 63, a first rotating shaft 64, a second gear 65, a stirring blade 66 and a conical block 67, and the middle of the inner top of the 7-type...

Embodiment 3

[0035] A paint spraying equipment for wood production, such as Figure 1-4 As shown, it includes a workbench 1, an n-type frame 2, a 7-type plate 3, a box body 4, a lower hopper 5, a stirring device 6 and a paint spraying device 7. The top of the workbench 1 is installed with an n-type frame 2, and the n-type frame 2 A 7-type plate 3 is installed on the top, a box 4 is installed in the middle of the top of the n-type frame 2, a lower hopper 5 is installed on the upper part of the right side of the box 4, and the lower hopper 5 is communicated with the box 4. There is a stirring device 6 , the stirring part of the stirring device 6 is located in the box 4 , and a paint spraying device 7 is arranged in the middle of the top of the n-shaped frame 2 .

[0036] The stirring device 6 includes a first motor 61, a first gear 62, a first bearing seat 63, a first rotating shaft 64, a second gear 65, a stirring blade 66 and a conical block 67, and the middle of the inner top of the 7-typ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com