Preparation of three-dimensionally ordered macroporous MnCo2O4 spinel-type composite oxide

A composite oxide and spinel-type technology, which is applied in metal/metal oxide/metal hydroxide catalysts, chemical/physical processes, incinerators, etc., can solve the problems of catalyst activity decline and achieve improved contact performance, The effect of large pore size and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Example 1: A three-dimensional ordered macroporous MnCo mentioned in the present invention 2 o 4 The preparation method of spinel type composite oxide is as follows:

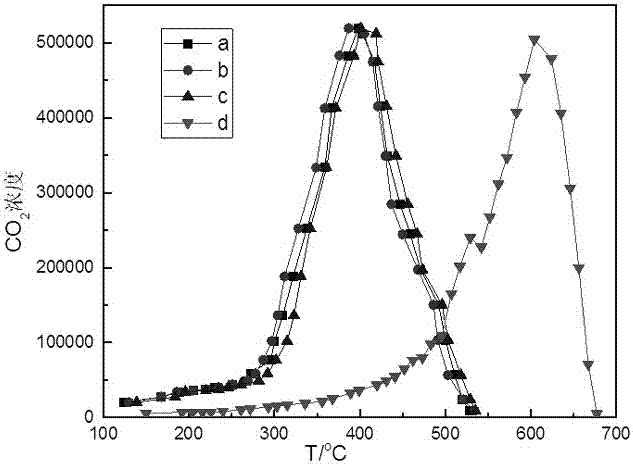

[0021] Weigh the metal salt manganese acetate tetrahydrate and cobalt nitrate hexahydrate according to the molar ratio of 1:2, add methanol or ethylene glycol and water mixture to dissolve at room temperature, stir for 5min; Weigh the glucose and add it to the above solution, and continue to stir for 10 minutes; add polymethyl methacrylate (PMMA) template, and soak for 5 hours; Wash with methanol, dry in a water bath at 40°C for 24 hours; put the dried sample in a tube furnace, heat up from room temperature to 300°C at a rate of 1°C / min under air with a flow rate of 80mL / min, and keep it for 2h. Then it was raised to 600°C at a rate of 1°C / min, kept for 4 hours and then cooled down to room temperature naturally.

[0022] The three-dimensional ordered macroporous MnCo mentioned in the present invention ...

Embodiment 2

[0024] Example 2: A three-dimensional ordered macroporous MnCo mentioned in the present invention 2 o 4 The preparation method of spinel type composite oxide catalyst is as follows:

[0025] Weigh metal salt manganese acetate tetrahydrate and cobalt nitrate hexahydrate according to the molar ratio of 1:2, add methanol or ethylene glycol and water mixture to dissolve at room temperature, stir for 10min; then weigh glucose according to a certain molar ratio and add to In the above solution, continue to stir for 15 minutes; add polymethyl methacrylate (PMMA) template, and impregnate for 6 hours; ℃ in a water bath for 12 hours; put the dried sample into a tube furnace, and raise the temperature from room temperature to 300°C at a rate of 2°C / min under air with a flow rate of 60mL / min, keep it for 2 hours, and then heat it up at a rate of 1°C / min The speed was increased to 600°C, kept for 4 hours and then dropped to room temperature naturally.

[0026] The three-dimensional orde...

Embodiment 3

[0028] Example 3: A three-dimensional ordered macroporous MnCo mentioned in the present invention 2 o 4 The preparation method of spinel type composite oxide catalyst is as follows:

[0029] Weigh metal salt manganese acetate tetrahydrate and cobalt nitrate hexahydrate according to the molar ratio of 1:2, add methanol or ethylene glycol and water mixture to dissolve at room temperature, stir for 10min; then weigh glucose according to a certain molar ratio and add to In the above solution, continue to stir for 10 minutes; add polymethyl methacrylate (PMMA) template, and soak for 5 hours; ℃ in a water bath for 20 hours; put the dried sample into a tube furnace, and raise the temperature from room temperature to 300°C at a rate of 1°C / min under air with a flow rate of 80mL / min, keep it for 1h, and then heat it up at a rate of 1°C / min The speed was raised to 700°C, kept for 5 hours and then naturally dropped to room temperature.

[0030] The three-dimensional ordered macroporou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com