Dual spectrum technology based leaf and stalk separating and cutting quality detection device and detection method

A detection device and dual-spectrum technology, which is applied in the field of comprehensive quality detection devices for threshing and destemming, can solve problems such as untimely feedback of detection data, single detection index, and long detection time, and achieve compact structure, good discrete effect, and occupation small area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Embodiment 1 detection device

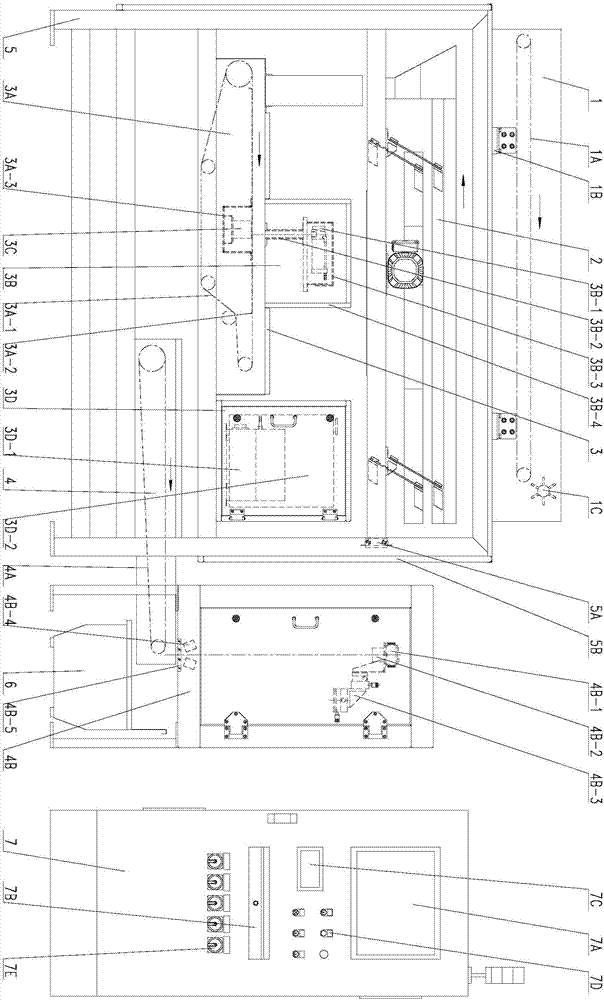

[0049] Such as figure 1 As shown, the detection device includes a paving device 1, a paver 2 positioned below the paving device 1, an X-ray detector 3 positioned below the paver 2, and a visible light detector positioned below the exit of the X-ray detector 3 4. The material receiving device 6, the frame 5 and the control cabinet 7 located below the exit of the visible light detector 4;

[0050] The material spreading device 1 includes a main belt conveyor 1A, a load cell module 1B and a material limiting roller 1C, and the main belt conveyor 1A and the material limiting roller 1C are respectively driven by a geared motor. Four sets of load cell modules 1B are installed between the left and right sides of the main belt conveyor 1A and the frame 5 . The material limiting roller 1C is located at the discharge port of the main belt conveyor 1A.

[0051] The paver 2 can adopt a spring plate type vibration conveyor or an exciting vibration ...

Embodiment 2

[0058] Embodiment 2 detection method

[0059] The first step is to spread the material and weigh: first, take a sample according to the tobacco industry standard, and when it is used for the detection of the leaf structure or the stem content rate in the leaf, take a sample (3000 ± 300) g on the leaf collection conveyor belt after the leaf has been threshed and destemmed; When detecting the long stem rate or the leaf content rate in the stem, take a sample (1000-1500) g on the conveyor belt of the tobacco stems after threshing and destemming. According to the online or offline usage, the sample can be spread evenly on the material spreading device 1 by manual or upstream equipment, and then the mass of the sample can be automatically obtained by static weighing through the rail weighing system.

[0060] The second step is uniform feeding: start the equipment through the control cabinet 7, so that the material passes through the material spreading device 1, the paver 2, the X-r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com